Mass flow meters directly measure the mass flow of fluids under various conditions. They are crucial for commercial measurement, laboratory procedures, and various industrial processes.

Sino-Inst offers custom mass flow meters for special requirements, such as low temperatures, high temperatures, and high pressures. Coriolis mass flow meters are ideal for liquid flow measurement. Thermal mass flow meters are suitable for most dry gases. We also offer flow meters capable of measuring the mass flow of powders.

What is a Mass Flow Meter?

A mass flow meter is a flow meter that measures the velocity of a fluid by measuring the mass of the fluid.

Methods of measuring fluid flow are volume and mass.

The volume of a fluid is a function of fluid temperature and pressure and is a dependent variable. The mass of a fluid is a quantity that does not change with time, temperature, and pressure.

Among the commonly used flow meters, most are volume flow meters. Such as orifice flow meters, laminar mass flow meters, turbine flow meters. Vortex flow meters, electromagnetic flow meters. Rotor flow meters, ultrasonic flow meters. And oval gear flow meters, etc.

Common mass flow meters are: Coriolis mass flow meters and thermal mass flow meters.

Read more about different mass flow meters working principle:

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

Different Methods of Mass Flow Measurement

① Direct mass flowmeter

That is, directly detecting the amount proportional to the mass flow, and the detection element directly reflects the mass flow. The Coriolis mass flowmeter is currently the most widely used.

② Derivational mass flowmeter

That is, using a combination of a volume flowmeter and a density meter to measure mass flow. The volume flow rate and fluid density are detected at the same time, and the output signal related to the mass flow rate is obtained through calculation. Thermal mass flowmeter is one of them.

③Compensated mass flowmeter

Simultaneously detects the volume flow rate of the fluid and the temperature and pressure of the fluid. Then, according to the relationship between fluid density, temperature and pressure. The density value of the fluid in this state is calculated by the calculation unit. Then the mass flow value of the fluid is calculated.

Types of Mass Flow Meters

Coriolis Mass Flowmeter

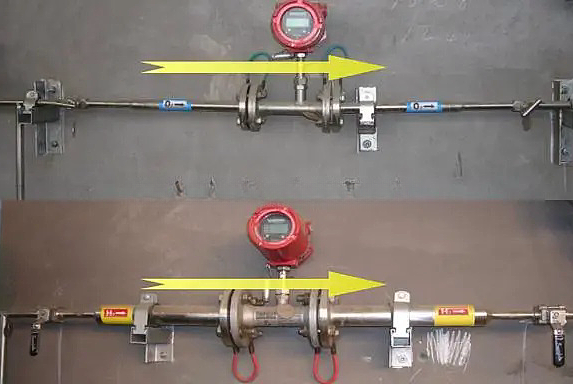

Coriolis mass flowmeters directly measure fluid mass flow based on the Coriolis effect. Their core principle is that as fluid flows through a vibrating tube, the Coriolis force causes the tube to distort. The mass flow rate is calculated by measuring the phase difference between the inlet and outlet.

They can simultaneously measure parameters such as density and temperature, with an accuracy typically ranging from ±0.1% to ±0.35%. They are widely used in various industries, including chemical, pharmaceutical, energy, rubber, paper, and food, and are particularly suitable for batching, loading, and custody transfer.

Thermal Mass Flow Meter

A thermal mass flow meter uses heating and temperature measurement to measure the thermal conductivity of a fluid. It contains two temperature sensing devices: a heater and a thermistor. When the thermal measuring device is placed in a fluid pipeline, its heat transfer efficiency changes. Based on the laws of heat conduction and thermal equilibrium, the fluid’s mass flow rate can be calculated.

They are generally used to measure the mass flow of dry gases. They feature low pressure drop, a wide flow range, accurate measurement, and stable performance. They can also be used to monitor and control extremely low gas flows.

Powder Mass Flow Meter

Powder flow meters utilize the most reliable electrostatic measurement technology. When airflow containing dust particles in a pipe passes through a fixed sensor, the weak current generated by the particles in motion is detected by the sensor and transmitted to a transmitter. The transmitter then filters, amplifies, and processes the current into a standardized output value that is linearly proportional to the dust flow rate.

Powder flow meters are used to precisely control the proportion of active ingredients in pharmaceuticals and are used to measure flour, sugar, cement, and chemical raw materials. They not only ensure precise mixing of raw materials but also help reduce energy consumption and material waste.

FAQ

More Flow Measurement Solutions

As a crucial component of process measurement and control, mass flow meters have become indispensable tools across various industries due to their high precision, high reliability, and broad application prospects.

Sino-Inst supplies Coriolis mass flow meters, thermal mass flow meters, and mass controllers. We support customization of parameters such as temperature, pressure, material, and signal output. If you need to purchase a mass flow meter or have any technical questions, please feel free to contact our sales engineers!

-1.jpg)