The float level switch is a common level measurement and control instrument in industrial production. It operates faster and has a longer service life than mechanical switches; it is more resistant to interference than electronic switches; and it can achieve multi-point control. It is widely used in shipbuilding, papermaking, printing, generator equipment, petrochemicals, food industry, water treatment, electrical engineering, dye industry, hydraulic machinery, and other industries.

Customized Case Sharing

A customer from the Philippines saw our product on our website and contacted us. The customer wanted to achieve four-point control of the diesel level in a storage tank. After multiple communications and drawing revisions, the final parameters are as follows:

- Float Level Switch

- Measuring Medium: Oil

- Measuring Range: 643mm

- 4 Control Points, from top to bottom:

- 236mm (Normally Open)

- 326mm (Normally Open)

- 506mm (Normally Closed)

- 596mm (Normally Closed)

- Ambient Temperature and Pressure

- ANSI 3-inch Class 150 Flange Connection

- Material: 304 Stainless Steel

- 220VAC

What Are The Components Of A Float Level Switch?

The liquid level measurement technology of a float-type level switch is based on the buoyancy of a float. Because of its low density and buoyancy, the float rises when the liquid level rises and falls when the liquid level falls. The liquid level is measured by utilizing the rise and fall of the float caused by changes in liquid level. Modern float switches are designed with high precision. The simplest single float switch consists of the following components: a hollow float with a built-in magnet, a guide tube for guiding the float, a reed contact inside the guide tube, and an adjusting ring to limit the movement of the float within the guide tube.

Working Principle

One or more reed switches are placed inside a sealed metal or plastic tube. One or more hollow floats containing ring magnets are then passed through the tube. A fixing ring controls the position of the float and the reed switch, allowing the float to float up and down within a certain range. When the liquid level rises to a set value, a set switching signal is emitted.

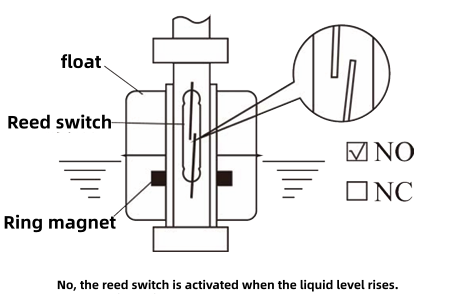

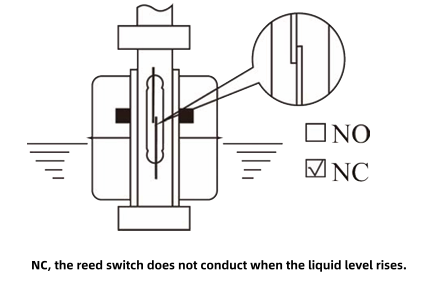

The reed switch consists of contact pieces located inside the sealed body. When a float switch is used in conjunction with a normally open reed switch, the contacts move closer together when a magnetic field is applied, allowing current to flow and completing the current loop. If a normally closed float switch is used, the contacts move further apart, breaking the current loop when a magnetic field is applied. This creates the opening and closing action, which can control the liquid level. The diagram below shows the positions of the float switch in normally closed (NC) and normally open (NO) states.

Features

- Multi-point control is possible.

- Switch positions can be customized to user needs.

- No power supply is required; using reed switches.

- Contact life reaches 2 million cycles.

- All switch wiring exits are in the same junction box, which requires external installation and reduces wiring costs.

- Compared to other types of level switches, it offers high cost-effectiveness with multiple switch control points.

- Junction boxes have an IP65 or higher protection rating.

- Conduits are available in PVDF, PP, PVC plastic, and SUS304 and SUS316 metal. Therefore, suitable products are available for use with acids, alkalis, solvents, and various fuels.

- The reed switch and wiring are completely isolated from the liquid, making it safe for use in high-temperature and high-pressure equipment.

Installation Requirements

- When the liquid fluctuates significantly, please install a wave deflector.

- Keep away from water inlets during installation.

- Clean regularly to prevent debris from clogging the float and causing malfunctions.

- Always use within the contact capacity to prevent burnout.

Application Industries

Petrochemical Industry: Level control for chemical raw materials, intermediate products, and finished product storage tanks.

Power Industry (Generator Equipment): Monitoring of cooling water and lubricating oil levels in generator sets; boiler water level control.

Shipbuilding Industry: Monitoring of fuel tanks, freshwater tanks, and ballast tank levels.

Food Industry: Level control in food processing, beverage, and dairy production.

Water Treatment Industry: Monitoring water levels during wastewater treatment; controlling the rise and fall of raw water and purified water levels.

How To Find A Suitable Float Switch?

To find the right float switch for your application, you should determine the following parameters:

- Measuring medium

- Medium density

- Process pressure

- Process temperature

- Number of switch contacts

- Position and function of each switch output

- Conduit length

- Electrical connection

- Process connection (threaded or flanged, and dimensions)

- Material compatibility (stainless steel, plastic, etc.)

Most importantly, you can directly provide us with a drawing of the tank dimensions and the height of the level point you need to control. As a float level switch manufacturer, we will create custom drawings based on your requirements. This avoids incorrect production dimensions that could lead to installation problems.

More Solutions For Level Measurement

Many wells are between 10 and 60 feet deep, while some can reach depths of 1000 feet. Therefore, deep well level sensors are the best choice when customers need to measure water levels in deep wells. Sino-inst deep well level sensors can measure depths up to 6561.68 feet (2000m). These level sensors are inexpensive, versatile, …

Read moreThe RF admittance level switch is a level detection device based on RF admittance technology, an upgrade from capacitive level technology. It is anti-fouling, more reliable, and more accurate. It is widely used for measuring liquids, slurries, and granular materials. It detects changes in the medium through the capacitance formed by the probe and the …

Read moreDue to its unique non-contact measurement capabilities, this intelligent radar level/liquid level meter accurately measures contaminants and corrosive media. Its 4-20mA and RS-485 output signals enable remote control. Its pulse operation allows for measurement of low-dielectric-constant media and is safe for use in various metal and non-metal containers, harmless to humans and the environment. It utilizes …

Read moreCapacitive level sensors are a crucial technology for monitoring the level of liquids and solid powders. Capacitive level sensors are a type of level transmitter that can be used for measuring the level of liquids, oils, and solids. They have no moving parts and are unaffected by water vapor, dust, or condensation. Capacitive level sensors …

Read moreThe Universal Intelligent Capacitive Level Transmitter is a liquid /material level transmitter suitable for measuring liquids, oils, solids, and interfaces. It is unaffected by water vapor, dust, or condensation. It offers long-term stable and reliable operation and is resistant to high temperatures and high pressures. This intelligent capacitive level transmitter uses a two-wire (loop-powered) 4-20mA/D …

Read moreAccurate liquid level detection is crucial for product quality and operational safety. Therefore, liquid level switches are essential components in industrial processes. They monitor and control liquid levels in tanks and containers. Level switches are widely used in industrial environments such as chemical and food production. Sino-Inst offers high-quality level switches and solutions. These includes …

Read moreRadar level gauges, with their non-contact measurement, high accuracy, and adaptability, have become the preferred technology for tank level monitoring. Using high-frequency microwave pulse or continuous wave technology, radar level gauges accurately measure levels by calculating the time difference between the electromagnetic wave’s transmission and its reflection back to the receiving antenna. In large tank …

Read moreRotary paddle level switches are suitable for controlling material levels in industrial production processes. When the material level reaches the upper or lower limit, the controller’s microswitch contacts output an alarm or control signal. Rotary paddle level switches offer a simple structure, reliable operation, and wide application, which make them an ideal instrument for measuring …

Read moreAccurate and reliable liquid level measurement is critical for many applications. Whether in industrial or civil fields, liquid level measurement can easily grasp the height of the liquid. That is the distance between the liquid and the top of the container. Including monitoring and controlling the level of liquids in storage tanks. Level measurement primarily …

Read moreA liquid level float switch is a simple, easy-to-use, safe and reliable industrial process liquid level controller. It detects single or multiple extreme liquid level points, outputs switching signals, and provides liquid level control. Liquid level float switches are specifically designed for liquid level detection, on-site signal transmission, and liquid level alarms in various small …

Read moreUltrasonic level transducers are widely used for level measurement in industrial tanks, cesspools, diesel containers, and other applications. They utilize ultrasonic technology to measure the liquid level in liquid or solid containers. This non-contact measurement method is used. These measurements are then converted into a standardized signal. This is used for monitoring, control, or displaying …

Read moreExplosion-proof ultrasonic level meters are specifically designed for level measurement in flammable and explosive environments. Die-cast aluminum alloy waterproof and explosion-proof housing. Sino-Inst explosion-proof ultrasonic level meter has an explosion-proof grade of Ex dⅡCT6 Gb. It is primarily used for monitoring the level of tanks containing media such as diesel, gasoline, and lubricating oil. Non-Contact Measurement …

Read moreLiquid nitrogen is a commonly used industrial gas with extremely low temperature, strong cooling capacity, and controllability. Liquid nitrogen has important applications in various industries, so it is important to monitor and control the liquid nitrogen level. Our liquid nitrogen tank level meter is a device used to monitor the liquid nitrogen level in ultra-low …

Read moreLevel transmitters with a magnetic, high-resolution measuring principle are used for continuous level measurement of liquids and are based on determining the position of a magnetic float following the magnetostrictive principle. This blog looks into each of the magnetic level instruments, their working principles, advantages, applications, comparability to other types of level measurement practical applications. …

Read moreGuided Wave Radar (GWR) level transmitters are level-measuring devices based on the time travel principle. They are widely used in industrial settings for liquid and solid material level measurement. GWR Type Level Transmitters are appropriate for harsh environments such as high temperature, high pressure, vacuum, steam, high dust, and volatile gases. This blog post investigates …

Read moreFirstly, let’s know what is Floating level?Float level switches run on the concept of buoyancy. The float rises or lowers when the liquid level alters and the location of the float is monitored by a switch or sensor. Whether you are carry off a primary residential water tank or operating a high-pressure industrial system, the …

Read moreFluid Level Measurement is very important in the industrial and civil fields. It is convenient to accurately grasp the height of the liquid, or the distance between the liquid and the top of the container. When you need Fluid Level Measurement, you have a variety of options in front of you. Including float level gauge, …

Read moreAmong various technologies available for level measurement, the float type level transmitter stands out for its naiveness, accuracy, and cost-effectiveness. All float-operated Level transmitters and sensors are based on the principle “the buoyancy force action on an object is equal to the mass of liquid displaced by the object.” We will explore float level sensors …

Read moreLevel measurement is the process of measuring the level of a liquid or solid material inside a tank, silo, container or reservoir. Measurement is calculated from the distance between the liquid or solid material surface and a predetermined reference point. Among the several applications of level measurement, the bin level measurement system plays an important …

Read moreIn different industrial processes, the measurement and control of fluid levels are crucial for ensuring creaseless operations. One effective way used for this intention is a level transmitter. A level transmitter, also known as a level sensor or level gauge, plays a critical role in accurately determining the level of liquids or bulk solids within …

Read moreBitumen is a byproduct of crude oil. The quality of bitumen and ease of production depends on the source and type of crude oil from which it is derived. On the other hand, Asphalt is a composite material with two primary ingredients: aggregates and bitumen. Bitumen and asphalt are hypercritical materials in construction, road paving, …

Read moreBin Level Indicators and Controllers can monitor the changes of materials in the silo in real time and accurately. Choosing the right Bin Level Indicators and Controllers can achieve efficient production planning and ensure the reliable transportation of finished products. In the industrial production process, a variety of liquid, solid, powder and other raw materials …

Read moreRotary Paddle Level Switch (controller) is a process instrument used to control the material level in open containers or closed and micro-pressure containers. When the material level reaches the high or low limit, the micro switch contacts of the controller output an alarm or control signal. Sino-Inst Rotary Paddle Level Switch (controller) can be installed …

Read more

Sino-Inst’s float level switch is a simple, easy-to-use, safe, reliable, and cost-effective level controller suitable for various level measurement applications. Customization is supported for conduit material and length, switch output position, process connections, and other specifications. If you have level control needs, please contact us.

-1.jpg)