Pressure transmitters are often installed in conjunction with manifolds, primarily for isolation, calibration, and venting. Manifolds control the input of the medium, ensuring measurement accuracy and safety. Manifolds are typically configured with a specified number of valves based on the required operating conditions. Common configurations include single-valve (2-valve), two-valve, three-valve, and five-valve manifolds.

When purchasing pressure transmitters or differential pressure transmitters, you can inform us of the type of manifolds you require.

Manifolds for Pressure Transmitters Are Important

Installing isolation manifolds and drain manifolds during transmitter installation is a key design element for ensuring the safe and reliable operation of the measurement system.

4 Types of Manifolds for Pressure Transmitters

We categorize Manifolds based on the number of valves configured.

1. Single-Shut-Off Manifolds

Also commonly known as instrument root valves, these are installed on process lines or equipment to isolate the instrument from the process medium.

2. Two-Valve Manifolds

Two-valve manifolds, also called dual-valve manifolds, consist of two on/off valves. In addition to the single-shut-off function, they also have a relief valve. Two-valve manifolds are used upstream of pressure transmitters (or pressure gauges).

Since pressure transmitters and pressure gauges require periodic disassembly and calibration, two-valve manifolds are typically used to release residual pressure in the pressure tapping branch line, and can also be used for sampling.

3. Three-Valve Manifolds

Three-valve manifolds are used in differential pressure transmitters or differential pressure gauges. High and low pressure are connected to two separate shut-off valves, with the middle valve being a balancing valve. When the differential pressure instrument is put into operation or under maintenance, to prevent excessive pressure on one side from exceeding the instrument’s range, the balancing valve must be opened first to achieve pressure balance between the high and low pressure sides, and then the shut-off valves on the high and low pressure sides should be opened or closed.

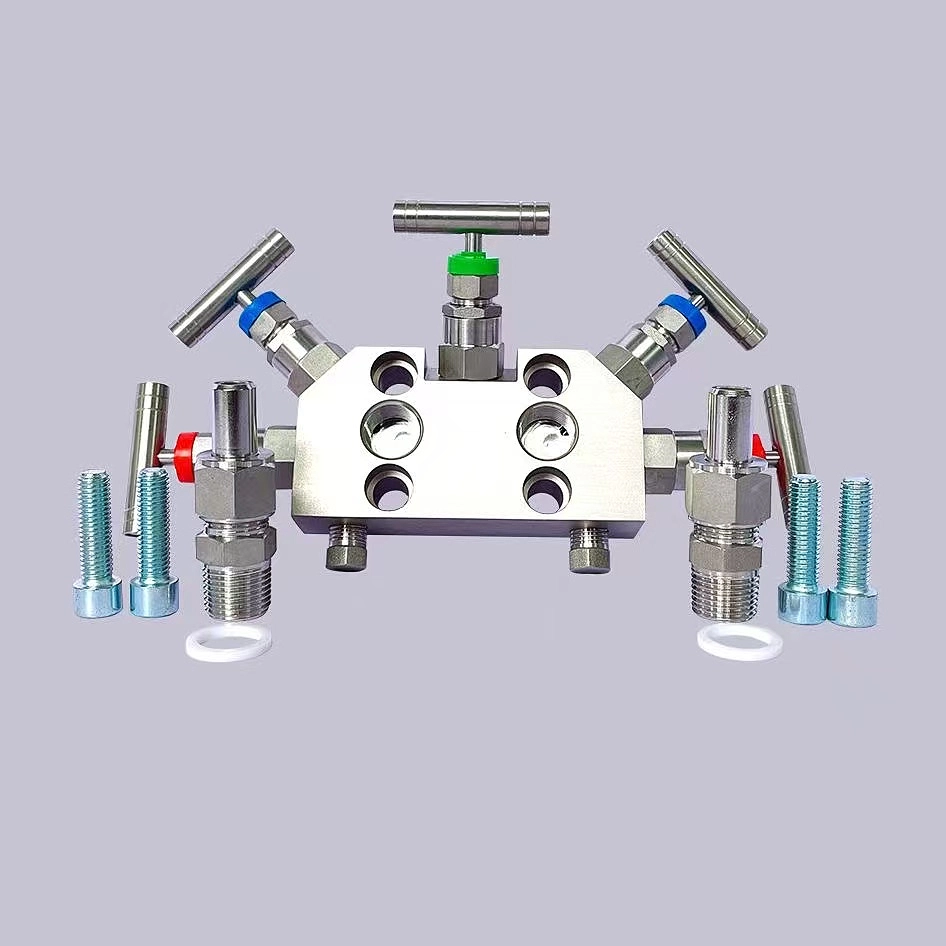

4. Five-valve Manifolds

A five-valve manifold is a three-valve manifold with two additional drain ports, serving a similar purpose. Essentially, a five-valve manifold adds drain valves to both the high and low pressure sides (for the same purpose as a two-valve manifold).

Purchase Pressure Transmitters/DP Transmitters with Manifolds

Our Sino-Inst pressure transmitters can all be configured with Manifolds, either as a complete product or as an accessory.

Why are three-valve Manifolds needed for differential pressure transmitters?

In most cases, differential pressure transmitters are configured with three-valve manifolds, primarily because:

- Improved measurement accuracy: The three-valve manifold effectively balances the pressure on the positive and negative sides, significantly reducing measurement errors caused by pressure fluctuations and temperature changes.

- Easier maintenance and repair: The three-valve manifold contains two shut-off valves that can control the positive and negative pressure sides separately. This greatly simplifies maintenance and repair.

- Extended transmitter lifespan: Adjusting the pressure through the balancing valve effectively prevents damage to the diaphragm due to unidirectional pressure, thus extending the transmitter’s lifespan.

- More accurate zero-point calibration: The three-valve manifold also keeps the positive and negative pressure sides of the differential pressure transmitter in a balanced state, resulting in more accurate zero-point calibration.

Manifolds Selection Guide

When selecting Manifolds for pressure transmitters, several factors need to be considered, such as media type, pressure range, temperature conditions, and interface size.

- For corrosive media, stainless steel or other corrosion-resistant materials should be selected; high-pressure environments require valves with higher rated pressure.

- During installation, ensure the valve is oriented correctly and connections are secure to prevent leakage.

- Regularly inspect the valve’s condition and replace worn parts promptly to extend its service life.

- Installation and maintenance by qualified professionals are recommended to ensure safety.

More Pressure Measurement Solutions

Natural Gas Pressure Transmitters – Selection and Products

Gas Pressure Measurement for Industrial Tanks and Pipelines

Industrial Hydraulic Pressure Sensors – Top Guide

Pressure Switch vs Sensor What You Need to Know

High-Temperature Media Pressure Measurement Case: 900-1200°C

Pressure Transmitter 4-20mA Guide: Testing and Troubleshooting

Sino-Inst is a professional manufacturer of pressure transmitters—specifically differential pressure transmitters. We can configure pressure transmitters with various accessories such as Manifolds, pressure taps, and remote diaphragms. We provide customized pressure measurement solutions for our users.

For example, in high-temperature steam pressure measurement, we can install a condensate tank (volume ≥100mL) between the isolation valve and the transmitter. The drain valve must be heat-resistant ≥450℃ (e.g., made of chrome-molybdenum steel), and a flow-limiting orifice plate (2mm diameter) should be installed in the drain pipe to prevent high-speed steam jets from scalding personnel.

We have extensive experience in pressure measurement services. If you need customized pressure transmitters, please feel free to contact us.

-1.jpg)