In the rapidly developing industrial sector, liquid level measurement is becoming increasingly important. Capacitive level transmitters are an important solution. They have no moving parts and are unaffected by water vapor, dust, or condensation. They are widely used in the petroleum, chemical, and pharmaceutical industries.

Capacitive level transmitters are a key technology for monitoring the levels of liquids and solid powders. They can be used to measure the levels of liquids, oils, and solids. In this article, we will delve into capacitive level transmitters to help you make an informed choice based on your application needs.

What Is a Capacitive Level Transmitter?

A capacitive level transmitter is a sensor that measures liquid level by detecting changes in capacitance. It is similar to a capacitor. It can measure liquids, powders, and solids in applications ranging from chemical processing to the food industry. Capacitive level transmitters utilize changes in capacitance to measure the level of the medium and liquid level within a container.

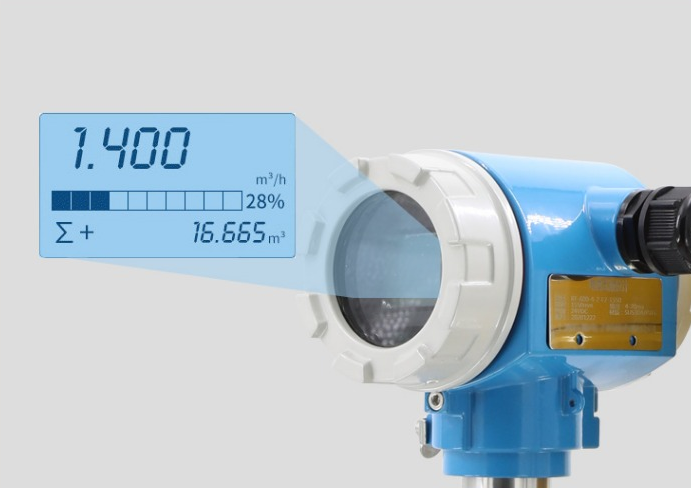

Capacitive level transmitters provide either continuous level measurement or switch signals. They are used for continuous monitoring in storage tanks. Suitable for all common fuels, oils, and coolants. This includes both conductive and non-conductive liquids.

Capacitive level transmitters are versatile, durable, and non-contact (or optionally direct-contact). They are suitable for harsh environments. Additionally, capacitive level transmitters feature low maintenance costs and a long service life. This makes them a cost-effective solution for numerous applications.

Performance Parameters

| Probe temperature resistance | -50~250℃ |

| Ambient temperature | -20~60℃ |

| Storage temperature | -55℃~+125℃ |

| Output Signal | 4-20mA, 4-20mA with HART communication, 485 communication, CAN bus communication |

| Power supply voltage | 12–28VDC |

| Mounting Methods | Threaded mounting: M20×1.5, M27×2.Flange mounting: DN25, DN40, DN50. Special specifications can be customized upon request. |

| Wetted materials | 316 stainless steel, 1Gr18Ni19Ti, or PTFE |

| Long-term stability | ≤0.2% FS/year |

| Temperature drift | ≤0.02%FS/℃ (within the range of 0–70℃) |

| Explosion Protection Rating | Intrinsically safe ExiaⅡC T6Flameproof ExdⅡC T5 |

| Protection Rating | IP67 |

| Intrinsic Safety Parameters | Ui: 28VDC, Ii: 93mA, Pi: 0.65W, Ci: 0.042μF, Li: 0mH |

Working Principle of Capacitive Level Transmitters

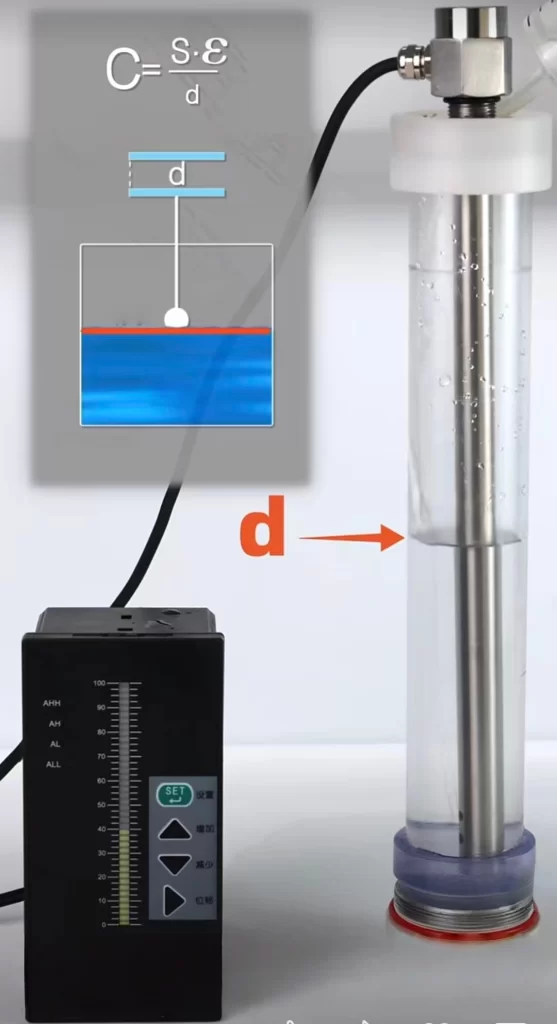

Capacitive level transmitters measure the liquid level in a container by detecting changes in capacitance. The change in capacitance is typically caused by the difference in dielectric constant between the liquid and air. As the liquid level changes, the capacitance of the capacitor also changes.

Within the container, the electrodes and the container wall, made of conductive material, form a capacitor. For a given electrode, when the dielectric constant of the measured medium remains constant, a fixed frequency measuring voltage is applied to the electrode. The current flowing through the capacitor depends on and is proportional to the height of the medium between the capacitor electrodes.

Components

A capacitive level transmitter essentially consists of a capacitor formed by the probe, the tank wall, and the liquid between them. The probe acts as one plate, and the tank wall acts as the other plate. The substance in the container acts as the dielectric material. For non-metallic tanks, a separate reference electrode is used.

Different substances have different dielectric constants. As the area of the probe covered by the liquid changes, the total capacitance also changes, thus enabling continuous liquid level measurement.

The dielectric constant of air is relatively low. Most liquids have a significantly higher dielectric constant. As the liquid level rises, the liquid displaces the air between the probe and the tank wall. This increases the average dielectric constant of that space, thereby increasing the capacitance. When the liquid level falls, air replaces the liquid, and the capacitance decreases accordingly.

Complex electronic circuits measure these minute capacitance changes and convert them into a standard output signal (e.g., 4-20mA, digital signal) representing the liquid level height.

Applications of Capacitive Level Transmitters

Oil and Gas Industry

Capacitive level sensors can monitor the levels of crude oil, natural gas, condensate, and water. These sensors provide real-time level data, allowing oil and gas companies to improve operational efficiency and reduce downtime.

Chemical and Petrochemical Industry

Capacitive level sensors monitor the levels of acids, solvents, crude oil, and chemicals in storage tanks. Chemical and petrochemical plants can prevent overflows, leaks, and spills. These sensors help optimize production processes and reduce waste.

Water and Wastewater Treatment

Capacitive level sensors monitor liquid levels in reservoirs, clarification tanks, and sewers. They measure various liquids including clean water, sewage, sludge, and chemicals. This enables water treatment plants and sewage treatment facilities to reduce operational costs and protect the environment.

Food and Beverage Processing

Capacitive level sensors measure liquid levels in diverse fluids like water, dairy products, beer, and soft drinks. Food and beverage manufacturers ensure consistent product quality while preventing overflows and leaks. Capacitive level sensors also detect conditions in food processing plants.

Advantages and Limitations of Capacitive Level Transmitters

Advantages of Capacitive Level Transmitters

High Sensitivity and High Accuracy

Capacitive level transmitters offer a wide measuring range. Zero point shift and range adjustment can reach ±30% FS, resulting in high measurement accuracy. They can effectively measure even minute changes in liquid levels. This high sensitivity is particularly important in industries requiring precise media level control.

Suitable for a wide range of media

Capacitive level transmitters accurately measure the level of liquids, slurries, and granular materials. They require no different sensing technologies. This reduces costs and simplifies inventory management. They deliver precise measurements even when media properties change.

Suitable for Harsh Process Conditions

Capacitive level transmitters operate effectively even in harsh environments. They maintain accuracy and reliability in high-temperature, high-pressure, or hazardous areas. Their robust design and low calibration requirements allow for long-term operation.

Low maintenance costs and extended service life

Capacitive level transmitters have a simple design and robust construction. This reduces wear-prone moving parts and mechanical components. They can operate reliably for extended periods without requiring extensive maintenance.

Limitations of Capacitive Level Transmitters

High Installation Requirements

The installation location and clearance must be precisely adjusted. Otherwise, measurement accuracy will be compromised. For complex liquid level scenarios, additional auxiliary structures may be required. This increases installation complexity.

Cost and Selection Complexity

While these sensors offer certain advantages, they also have a higher initial cost. This higher cost stems from the high-quality materials and electronic components used in their design.

Limitations in Certain Applications

Capacitive level transmitters face challenges in certain specific environments. This limits their general applicability. They are not suitable for substances with extreme dielectric constants.

Compensation Methods for Capacitive Level Transmitters

1. Fixed-Point Calibration Method

A capacitive level switch or tuning fork level switch is installed horizontally in the middle of the measured liquid level range to automatically compensate for the dielectric constant of the capacitive level meter.

When the liquid level reaches this position, the capacitance changes or the tuning fork stops vibrating. A switch signal is then generated to make the level meter reading match the liquid level value corresponding to that point. This eliminates the influence of changes in the dielectric constant (εl).

This method is suitable for situations where the dielectric constant changes slowly, such as liquid level measurement in raw material, semi-finished product, and finished product storage tanks.

2. Compensating Capacitive Sensor Method

A compensating capacitive electrode is installed at the bottom of the container. This electrode is always immersed in the measured medium and measures a signal proportional to the dielectric constant.

This signal is input to the instrument, and the instrument’s internal divider removes the output signal of the measuring electrode. The output signal of the divider is only related to the liquid level and is independent of εl.

This method is suitable for situations where the dielectric constant of the measured liquid changes rapidly, such as liquid measurement in reaction vessels.

Selecting the Appropriate Capacitive Level Transmitter

What aspects should be considered when selecting a capacitive level transmitter?

- Medium characteristics. Understand whether the medium being measured is electrically conductive. Also consider the temperature, pressure, corrosiveness, and tendency to crystallize of the medium being measured.

- Installation Conditions. Consider the required measurement range of the level transmitter. Also, consider the power supply method at the work site and whether on-site display of the measured liquid level data or remote transmission functionality is required.

- Temperature and Pressure Range. The operating temperature range of capacitive level transmitters is typically -80-200℃; special models are required for temperatures outside this range. The pressure limit is generally 600kPa; reinforced designs are needed for high-pressure environments. The measurement range can reach (0.1-20)m.

- Probe Type. The sensing probe can be designed as a rod or cable type, depending on the working conditions. Rod-type probes are suitable for clear water and ordinary solutions with a range of ≤ 2m. Cable-type probes are suitable for ranges >2m or for viscous or easily crystallizing media.

- Connection Method. The connection method can be customized as flange type, threaded type, or a special type according to requirements. The wetted parts material can also be selected based on the corrosiveness of the measured medium.

Installation

Installation Location Selection

- Keep away from direct sunlight, high temperature, high pressure, or vibration.

- The sensor should be installed at a distance of 1/6 of the tank diameter from the tank wall. The minimum distance is 200mm.

- Do not install it above or in the center of the material inlet.

- Avoid installing the sensor in locations where material may accumulate between the probe and the tank wall.

Mechanical Installation

- Insert the probe. Ensure the probe has sufficient length to extend below the connector.

- Use clamps or mounting accessories for a secure, leak-proof installation.

- For metal tanks, some sensors use the tank wall as a reference. Use Teflon tape for insulation if necessary to reduce noise.

Wiring and Electrical Connections

- Connect the correct power supply and ground according to the manufacturer’s guidelines.

- Use appropriate cables. Protect cables from damage or interference.

- Securely connect the wires. Do not overtighten the connectors.

- Match the wiring to the controller requirements (PNP/NPN, normally open/normally closed).

FAQ

More Level Measurement Solutions

Capacitive level transmitters play a crucial role in industrial applications. They are suitable for level measurement of both liquids and solids. They are widely used in industries such as automotive, food and beverage processing, and chemical and petrochemical industries. They provide accurate measurements even in harsh environments, making them an ideal choice for level monitoring.

Sino-inst’s capacitive level transmitters are specifically designed for high-precision, non-contact level measurement. If you need to purchase a capacitive level sensor or have any technical questions, please feel free to contact us.

-1.jpg)