When using liquid nitrogen tanks, it’s crucial to constantly monitor the liquid nitrogen level inside. Replenishing the tank as needed ensures the sample remains at a constant -196°C, preserving its activity. Generally, replenishment is necessary when the level drops below one-third. Insufficient liquid nitrogen will prevent complete coverage of the sample, causing the internal temperature to rise and ultimately damage the sample.

However, liquid nitrogen tanks are not transparent, making it impossible to directly observe the internal liquid level. Even with the lid open, the cryogenic liquid nitrogen produces a significant amount of white mist upon contact with air, obscuring visibility and making it impossible to visually determine the liquid level. So, how can we correctly check the liquid level in a liquid nitrogen tank?

Method 1: Manual Measurement

The simplest method is manual measurement. Find a long, solid wooden stick and insert it directly into the bottom of the liquid nitrogen tank you want to measure. Wait a few seconds and then remove it. You will see frost forming on the part of the stick that was immersed in liquid nitrogen. By observing the frost line on the stick, you can determine the liquid nitrogen level in the tank.

There are also professional liquid nitrogen level gauges that measure the liquid level using the same principle.

However, manually measuring the liquid nitrogen level based on experience is inevitably prone to error. Therefore, more professional measuring instruments are also available for liquid level detection.

Method 2: Weighing Measurement

First, weigh the empty liquid nitrogen tank. Then, weigh the tank when it is filled with liquid nitrogen. Subtract the weight of the empty tank from the weight of the filled tank to get the weight of the liquid nitrogen in the tank. Calculate this to obtain the liquid level.

However, this method requires regular weighing and calculation, which is cumbersome, and the accuracy of the data may not be guaranteed.

Method 3: Pressure Measurement

The liquid level is indirectly calculated by measuring the pressure exerted by liquid nitrogen on the tank.

This method is suitable for situations where the pressure can be measured through an opening at the bottom of the tank. This requires a dedicated cryogenic pressure transmitter. However, the measurement accuracy can be affected by various factors, such as the tank material and the ambient temperature.

If the pressure at the bottom of the tank cannot be obtained, then measurement is not possible.

Method 4: Cryogenic Level Sensor

The cryogenic level sensor uses the capacitive principle to measure the liquid level of a medium. It can continuously measure the liquid nitrogen level in a container, outputting a 4-20mA signal. The real-time liquid level can also be accurately read through a digital display screen.

The cryogenic level sensor is a customized product for liquid level measurement in low-temperature environments such as liquid nitrogen, LNG, and liquid ammonia.

The Sino-Inst cryogenic level sensor supports customization of a 50mm ~ 3000mm range. Optional 4~20mA/0~5V/RS485/RS232 signal output. Widely used in liquid level monitoring of LN2 and other low-temperature medium storage tanks.

Case – Liquid Nitrogen Level Measurement

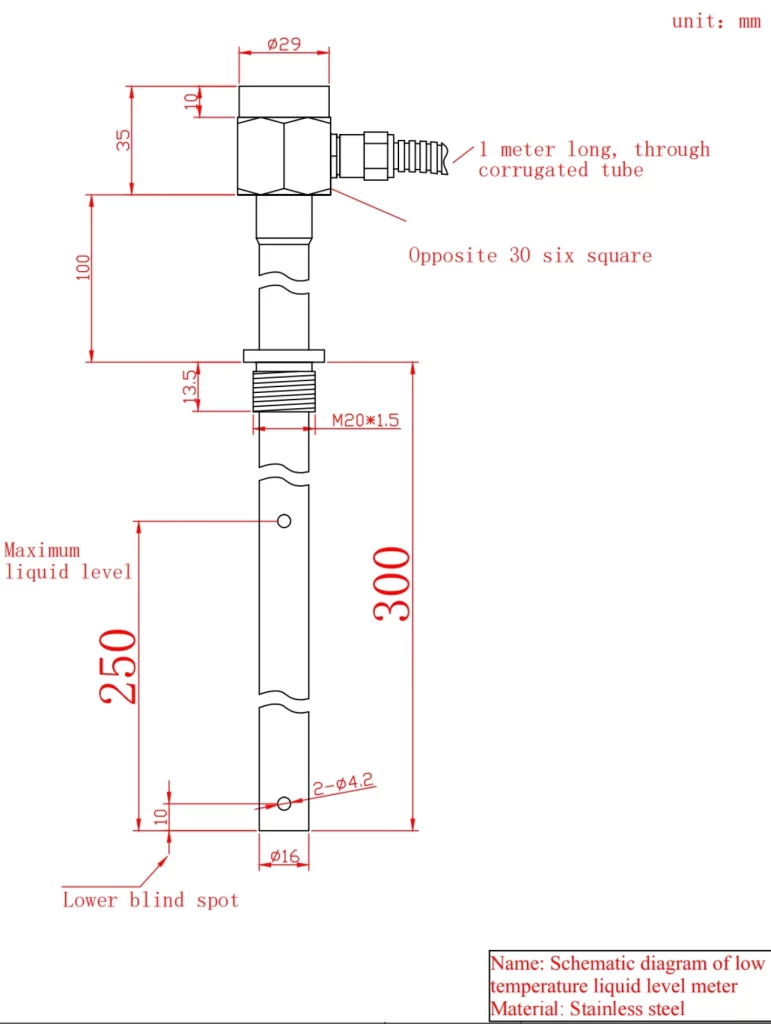

A customer from the Middle East consulted us about low-temperature liquid level meters. With our help, the customer confirmed the technical parameters.

- Low temperature liquid level meter

- Measure liquid nitrogen

- Internal pressure 1.5MPa.

- Output signal: 0-5V

- Total length: 300 mm

- Highest liquid level: 250 mm

- Thread is M20*1.5

- 24vdc

- No display

More Level Measurement Solutions

In summary, there are various methods for monitoring the liquid nitrogen tank level, each with its own characteristics and applicable scope. When selecting a specific monitoring method, it is necessary to comprehensively consider factors such as the model, specifications, application environment, and cost of the liquid nitrogen tank.

Furthermore, regardless of the method used, regular calibration and maintenance are required to ensure the accuracy and reliability of the liquid level measurement.

Sino-Inst supports the customization of cryogenic storage tank level gauges, including dimensions, temperature, pressure, digital display, and signal output.

-1.jpg)