Many wells are between 10 and 60 feet deep, while some can reach depths of 1000 feet. Therefore, deep well level sensors are the best choice when customers need to measure water levels in deep wells. Sino-inst deep well level sensors can measure depths up to 6561.68 feet (2000m). These level sensors are inexpensive, versatile, and easy to install.

A deep well level sensor is a device specifically designed to measure and monitor water levels in deep wells or boreholes. These sensors can employ a variety of technologies. These include pressure measurement, ultrasonic sensing, and even simple probes. They can withstand the harsh environments of deep well applications and provide accurate and reliable water level measurements.

Principle of the Deep Well Water Level Sensor

The working principle of a deep well water level sensor is based on hydrostatic pressure. Hydrostatic pressure refers to the pressure exerted by the water column above the sensor. Water pressure is directly proportional to the water level. Therefore, by measuring water pressure, the water level can be indirectly measured.

When the liquid pressure in the deep well acts on the sensor probe, the water level will rise or fall. The change in static pressure exerted by the liquid on the probe is converted into an electrical signal. Then, through temperature compensation and signal processing, it is converted back into a standard electrical signal.

The formula for liquid surface pressure is: P = ρgh + P1, where:

- P: Sensor liquid surface pressure.

- ρ: Density of the measured liquid (default value during debugging is 1 g/cm³)

- g: Gravitational acceleration (default value during debugging is 9.8 m/s²)

- P1: Internal pressure during encapsulation (≈101.3 kPa)

- h: Depth of sensor immersion in liquid.

Types of Well Water Level Sensors

Submersible Level Transmitters

Submersible level sensors are devices that measure liquid height based on hydrostatic pressure. They employ a high-performance diffused silicon piezoresistive pressure sensor as the measuring element. This pressure is directly proportional to the liquid depth.

The signal is converted into a standard (current or voltage) signal output by a signal processing circuit. The output signal has a linear relationship with the liquid level depth, thus allowing for the measurement of liquid level depth.

Submersible level transmitters typically have a measurement range of up to 200 meters. They are widely used in industrial containers, storage tanks, reservoirs, and other similar applications.

In addition, Sino-inst offers stainless steel submersible level sensors. This sensor is a pneumatically guided level transmitter. It can be used to measure the level of high-temperature, corrosive, and wastewater liquids. It also supports multiple signal outputs, including 4~20mA, 1~5V, and RS485.

Features

- Accuracy up to ±0.25%FS, supports multiple measurement ranges (0~500 meters) for customization.

- Stable and reliable performance, usable in harsh outdoor environments.

- Waterproof and corrosion resistant. Operates stably in media/ambient temperatures from -20 to 85℃.

- Supports 4~20mA current, voltage, digital signal, and wireless transmission (such as GPRS) output.

- Equipped with a solid-state structure and no moving parts, offering a lifespan of over 10 years.

- Its measurement range is up to 200~2000mH2O.

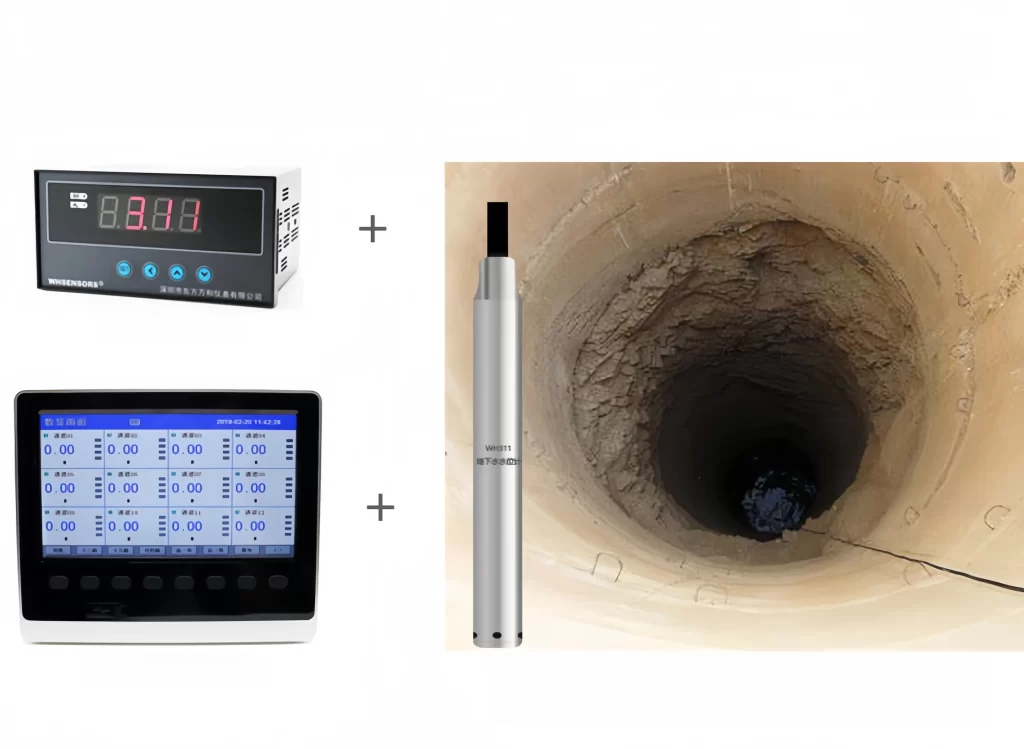

Deep Well Water Level Sensor

The deep well water level sensor is a submersible level transmitter specifically designed for deep well measurement applications. Its measuring range is up to 200~2000 mH2O. The temperature range covers -40 to 100℃. It also supports outputs of 4~20mA, 4~12~20mA, and RS485.

Compared to ultrasonic well depth sensors, deep well water level sensors offer a larger customizable measuring range and a more affordable price! They are widely used in deep well level measurement, groundwater level monitoring, and geothermal well measurement.

Features

- Utilizes an OEM pressure sensor with a stainless steel isolating diaphragm as the signal measuring element.

- Features internal sealing and a dual-isolation chamber design.

- Enhanced by lightning strike and open-circuit interference protection, providing strong anti-interference capabilities.

- Excellent stability, condensation-proof, and liquid-proof.

- Low temperature drift coefficient and high accuracy.

- Customers can assemble the cable themselves.

Chemical Level Sensor with PTFE Probe-Submersible

Chemical level sensors with PTFE probes are suitable for open-type hydrostatic level measurement. They are mainly used to measure highly corrosive liquids such as hydrochloric acid, sulfuric acid, and nitric acid, as well as seawater, chemical wastewater, and electroplating wastewater.

This chemical level sensor consists of a PTFE gas collection cylinder, a PTFE capillary tube, and a junction box. It features high corrosion resistance and wide applicability. It can be used for level measurement of high-concentration strong acids and alkalis in various industries.

Like other hydrostatic level sensors, the Sino-inst submersible chemical level sensor with a PTFE probe uses the hydrostatic method for measurement.

Features

- Utilizes a diffused silicon piezoresistive sensor.

- The probe is made of corrosion-resistant PTFE material.

- An LCD display is optional.

- The probe features an insertion-type measurement method for easy installation.

- Threaded or flange mounting options are available.

- The sensor itself features automatic temperature compensation.

Main Features of Deep Well Water Level Sensor

High measurement accuracy

The measurement accuracy of deep well water level sensors can reach ±1 cm. They can capture minor water level fluctuations.

Strong environmental adaptability

The measurement range of deep well water level sensors is 0 to 200 to 500 to 1000 to 2000 mH2O. The housing of deep well water level sensors is made of 316L stainless steel or engineering plastics. They can withstand temperature differences from -40°C to 100°C and strong corrosive environments. Please provide the text you would like translated.

Waterproof design

Deep well water level sensors usually have a waterproof function. This enables them to accurately measure water levels at different depths.

Multiple output options

Deep well water level sensors typically offer multiple output options. For instance, analog signals and digital signals are common. Analog signals are often 4-20mA current signals or 0-5V voltage signals. Some models support RS485 communication protocol for digital signals.

Applications of Deep Well Water Level Sensor

- Water resource management

Deep well water level sensors are mainly used to monitor water level changes in deep wells, geothermal wells, etc. They can record water level data in real time and upload it to the platform.

- Groundwater monitoring

Deep well water level sensors can be used to monitor changes in groundwater levels. They can assess the health of aquifers and manage water resources.

- Industry and environmental protection

Deep well water level sensors can be used in industrial wastewater and sewage treatment. Monitoring liquid level changes can optimize the process flow. Please provide the text you would like translated.

- Irrigation and Agriculture

In irrigation systems, deep well water level sensors can ensure that the water level in agricultural irrigation systems is appropriate. This can optimize water usage and crop growth, and reduce water waste.

- Environmental Monitoring

Deep well water level sensors can be used in environmental research to track the water levels of natural or artificial wells for ecological studies or conservation efforts.

How to Check The Well Water Level?

Common Measurement Methods:

Rope Method

A graduated conductive rope (such as a single-strand wire) is connected to a counterweight and a multimeter, and lowered into the well. When the multimeter detects continuity, the reading is the water level depth.

This method is suitable for temporary monitoring or when equipment is insufficient; it is low-cost and simple to operate.

Hand Probe Method

A probe is directly inserted into the well, and the water level is estimated by the exposed length. This method can quickly determine shallow water levels.

Instrument Monitoring Method

This typically uses contact instruments, such as hydrostatic sensors, which automatically record data based on changes in water pressure. This method has an error of less than 1 cm, supports a 2000-meter range, and is suitable for long-term monitoring.

Installation and Maintenance Recommendations for Deep Well Water Level Sensors

Installation

The following steps should be followed when installing a deep well water level sensor:

- Select an appropriate installation locati0n. The sensor should be installed at a position where the groundwater level is relatively stable.The monitoring well should avoid areas with sediment accumulation.

2. Drill a hole. The diameter of the hole should be larger than the outer diameter of the sensor. This will facilitate the smooth lowering of the sensor.

3. Install the sensor. Then place the sensor in the drilled hole. Use a well wall fixing frame or cable clamps to securely fix the equipment.

4. Test the sensor. After installation, calibrate the equipment’s zero point. Compare the measured data with manual measurements to adjust the error to within ±0.25%F.S. Test the automatic data collection function and check the completeness and continuity of the data.

Maintenance

Maintaining the deep well water level sensor requires following these steps:

1. Regularly inspect the sensor’s appearance. Check for damage or corrosion.

2. Regularly clean the sensor. Regularly clean the filter and the sensor exterior, and check for aging of the IP68 protection rating seals. Stainless steel protective sleeves are required for downhole installations.

3. Regularly calibrate the sensor. Return it to the factory for calibration annually or perform on-site comparison using a standard water pressure calibrator. Allow the equipment to stand for 24 hours before calibration.

4. Check the wireless transmission module signal strength. Ensure a stable power supply voltage (supports DC 6-30V wide voltage range).

FAQ

More Level Measurement Solutions

Deep well level sensors are essential tools for measuring water levels. They can measure water depths of 1000 meters and 2000 meters. Therefore, they are ideal water level measurement instruments for deep well surveying.

Deep well level sensors are specifically designed for deep well surveying applications. They provide accurate and reliable water level measurements. They offer advantages such as low temperature drift coefficient, high accuracy, and high tensile strength.

Sino-Inst offers a wide range of water level measurement equipment, including hydrostatic sensors, water pressure sensors, and pressure sensors. Please contact us if you have any questions or needs.

-1.jpg)