The selection of an appropriate variable area flow meter, commonly known as a rotameter, represents a foundational decision in numerous industrial and laboratory settings. This process demands a nuanced consideration of multiple interacting factors, extending beyond simple flow rate measurement.

These include the density, viscosity, and corrosiveness of the medium and their direct impact on meter performance and life. The pipe diameter, the required flow range, the pipe temperature, and the pressure, among other factors, must be considered systematically. By systematically considering these core issues, users can procure a device that provides reliable, accurate, and cost-effective flow measurement for their specific application.

Check 1: Understanding Your Fluid’s Character

In fluid measurement, the “material” is the gas or liquid flowing through your pipes. Its unique personality—its physical and chemical properties—dictates how it will behave inside a variable area flow meter and, consequently, which meter design is suitable.

The principle of a rotameter is an elegant balance of forces: the upward force of the fluid flow pushing on a float against the downward force of gravity. Any property of the fluid that affects this balance must be accounted for.

The Role of Density and Specific Gravity

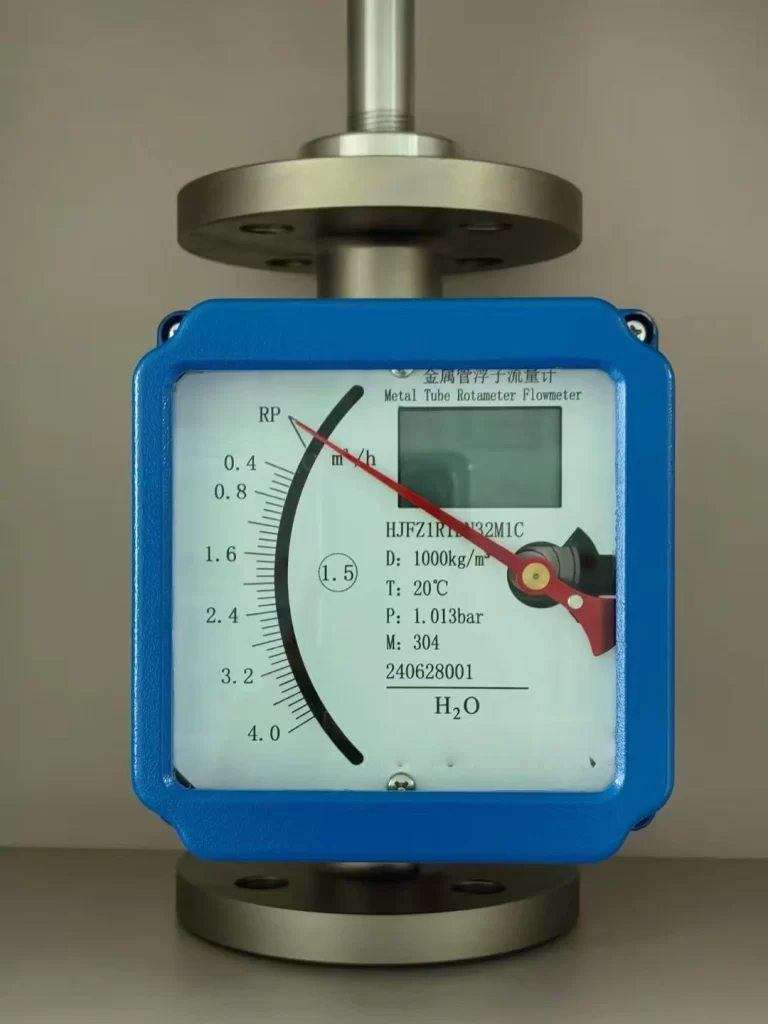

The fluid exerts a buoyant force on the float within the meter, and this force is directly related to the fluid’s density. A denser fluid will provide more “lift” to the float. Most standard variable area flow meters are calibrated for a specific fluid, often water for liquids or air for gases, at standard conditions. If your process fluid has a different density, the standard scale on the meter will be misleading.

For example, using a water-calibrated rotameter to measure a brine solution, which is denser than water, will cause the float to rise higher than it should for a given volumetric flow. This results in an erroneously high flow reading. The opposite occurs with a less dense fluid like gasoline. To counter this, you must either order a meter with a custom-calibrated scale specific to your fluid’s density (or specific gravity) or use a conversion factor to correct the readings from a standard scale.

The Challenge of Viscosity

Viscosity primarily affects the drag forces acting on the float. While density affects the buoyant force, viscosity introduces a “sticky” or frictional force. For low-viscosity fluids, this effect is often negligible. However, as viscosity increases, the viscous drag becomes a significant upward force, adding to the lift provided by the fluid’s velocity. This additional lift will cause the float to rise higher, again leading to an inflated flow reading.

We have developed floats with specific shapes designed to minimize the effects of viscosity. A sharp-edged float, for instance, is more immune to viscosity changes than a simple spherical float because the flow separates cleanly from its edges, reducing the surface area subjected to viscous drag.

Most manufacturers will provide a viscosity ceiling for their standard rotameters, typically around 100 centipoise (cP). If your fluid’s viscosity exceeds this limit, or if it varies significantly with temperature, you must consult with the supplier to select a viscosity-compensating float or consider an entirely different flow measurement technology, such as an electromagnetic flow meter, which is immune to viscosity effects.

Corrosive and Erosive Properties

The final aspect of a fluid’s character to consider is its potential to attack the flow meter from within. This attack can be chemical (corrosion) or physical (erosion). A highly acidic or alkaline fluid can dissolve the very materials of the meter’s tube and float, leading to catastrophic failure. Similarly, a fluid carrying abrasive particles, like a slurry, can physically wear away the components, altering the delicate geometry of the float and tube, which inevitably destroys the meter’s calibration.

A comprehensive chemical profile of your fluid is required. You must know if it is an acid, a base, a solvent, or if it contains suspended solids. This knowledge allows you to filter your options down to only those variable area flow meters constructed from materials that can withstand the chemical and physical challenges posed by your process fluid, ensuring both the longevity of the instrument and the safety of the operation.

Check 2: Defining the Operational Environment

After characterizing the fluid, our attention must turn to the world in which the flow meter will live: its operational environment. The pressures and temperatures of a process are not static figures on a datasheet; they are dynamic forces that exert constant stress on the instrument. A variable area flow meter is, at its core, a pressure-containing vessel. Its ability to withstand the rigors of the application’s environment is paramount for safe and reliable operation.

Pressure: The Constant Squeeze

Every flow meter has a maximum operating pressure rating, a limit determined by the strength of its materials and the integrity of its seals. This rating must comfortably exceed the highest pressure your system will experience, including any potential spikes or surges from pump startups or valve closures. Think of it as a safety margin. If your system normally operates at 100 PSI, selecting a meter rated for only 110 PSI is cutting it too close. A sudden pressure surge could compromise the seals or, in the case of a glass tube rotameter, even fracture the tube.

The material of the flow tube is the primary determinant of its pressure handling capability.

Glass tubes, while offering the benefit of direct flow visualization, are the most fragile and typically limited to lower pressure applications, often below 200 PSI.

Plastic tubes (like polycarbonate or polysulfone) offer a step up in durability and impact resistance but still have modest pressure ratings.

For high-pressure applications, there is no substitute for metal. Durable metal tube rotameters are constructed from stainless steel or other alloys and can handle pressures into the thousands of PSI.

Read more about: What Is Variable Area Flow Meter?

Temperature: The Silent Stressor

Temperature affects a variable area flow meter in two critical ways. First, like pressure, it stresses the materials of construction. High temperatures can soften plastics, compromise the elasticity of seals (O-rings), and reduce the overall strength of the meter body. Conversely, cryogenic temperatures can make materials brittle and prone to fracture. Every component of the meter, from the tube to the seals, has a specific operating temperature range that must be respected.

Second, temperature changes the properties of the fluid itself. As we discussed, fluid density and viscosity are often temperature-dependent. A liquid’s density generally decreases as it gets hotter, while its viscosity also tends to decrease.

For gases, the relationships are more complex. A rise in temperature at constant pressure will decrease a gas’s density, significantly affecting the reading. Because the rotameter is fundamentally a density-sensitive device, failing to account for the operating temperature can introduce substantial measurement errors. When specifying a meter, you must provide the operating temperature, not just the ambient temperature, so that the scale can be calibrated or corrected accordingly.

| Tube Material | Typical Max. Pressure | Typical Max. Temperature | Advantages | Disadvantages |

| Borosilicate Glass | ~150 PSI (10 bar) | ~250°F (121°C) | Excellent visibility, low cost, high chemical resistance | Fragile, low pressure/temp limits |

| Polycarbonate | ~100 PSI (7 bar) | ~130°F (54°C) | High impact strength, good visibility, low cost | Lower chemical and temp resistance |

| Polysulfone | ~150 PSI (10 bar) | ~212°F (100°C) | Good chemical resistance, higher temp than PC | More expensive than PC, can be attacked by some solvents |

| Stainless Steel | >1500 PSI (100 bar) | >572°F (300°C) | Extreme durability, high pressure/temp capability | Opaque (requires external indicator), highest cost |

Check 3: Balancing Flow Range with Required Precision

Once we have a firm grasp of the fluid’s nature and the environment’s demands, we must confront the central purpose of the instrument: measuring flow. This involves more than just picking a meter that can handle the expected flow rate. It requires a thoughtful consideration of the entire range of flows you need to measure and the degree of precision your process demands. The concepts of rangeability (or turndown ratio) and accuracy are deeply intertwined in the world of the variable area flow meter.

Defining Your Flow Range and Turndown Ratio

Every flow meter has a minimum and maximum flow it can accurately measure. The ratio of the maximum to the minimum is known as its turndown ratio. A typical variable area flow meter has a turndown ratio of 10:1. This means if a meter’s maximum capacity is 100 gallons per minute (GPM), it can accurately measure down to about 10 GPM. Below that minimum, the forces on the float are too weak and unstable to provide a reliable reading.

For instance, if your normal flow is 15 GPM, choosing a 0-100 GPM meter would mean your normal reading is at just 15% of the scale. A much better choice would be a 0-25 GPM meter, which would place your normal operating point at a much more readable and accurate 60% of the scale.

Understanding Accuracy and Repeatability

Accuracy is a measure of how close a measurement is to the true value. It is often expressed as a percentage of the full-scale reading (% FS) or as a percentage of the actual reading (% AR). For variable area flow meters, accuracy is almost always specified as a percentage of full scale.

A meter with a 100 GPM range and an accuracy of ±2% FS is accurate to within ±2 GPM (2% of 100) across its entire range. This is a critical point. At full scale (100 GPM), the potential error is 2 GPM, or 2% of the reading. But at 10 GPM, the potential error is still ±2 GPM, which is a staggering 20% of the reading. This demonstrates why operating a rotameter at the low end of its scale is so detrimental to accuracy.

Repeatability, on the other hand, is the ability of the meter to give the same reading for the same flow rate time after time. A meter can be very repeatable but not very accurate. The readings might be clustered tightly together, but far from the true value. For many process control applications, repeatability is actually more important than absolute accuracy. A highly repeatable meter allows for consistent process outputs, even if the absolute flow value is slightly off.

Standard variable area flow meters typically offer repeatability around ±0.5% of the full scale, which is quite good for such a simple mechanical device. If your application demands higher accuracy than the typical ±2-5% FS of a standard rotameter, you may need to consider a precision-machined model or a different technology, like a turbine flow meter.

Read More about: Flow Meter Accuracy Guide

| Flow Meter Technology | Typical Accuracy | Typical Turndown | Viscosity Effects | Cost |

| Variable Area | ±2-5% FS | 10:1 | High (unless compensated) | Low |

| Turbine | ±0.5% AR | 10:1 to 20:1 | Moderate | Medium |

| Electromagnetic | ±0.5% AR | 20:1 to 40:1 | None | High |

| Ultrasonic (Clamp-on) | ±1-2% AR | 40:1 | Low | High |

| Vortex | ±1% AR | 10:1 to 20:1 | Low | Medium-High |

Check 4: Selecting Materials for Durability and Compatibility

The choice of materials for a variable area flow meter dictates the instrument’s lifespan, safety, and reliability. The meter’s wetted parts—the components that come into direct contact with the process fluid—must be able to resist chemical attack and physical wear while maintaining their structural integrity under the process conditions. The two most important components to consider are the flow tube and the float.

The Flow Tube: Window or Wall?

The flow tube forms the body of the meter and the tapered conduit through which the fluid flows. The choice of tube material is a primary decision driven by the pressure, temperature, and chemical compatibility requirements identified in our earlier checks.

Glass (Borosilicate): The classic choice, offering the unparalleled benefit of allowing you to see the fluid and the float directly. This visual confirmation is incredibly valuable for troubleshooting, allowing you to spot oscillations, contamination, or bubbles in the line. However, glass is fragile. Its use is restricted to lower pressure and temperature applications and to fluids that are not highly alkaline or contain hydrofluoric acid, which attacks glass.

Plastic (Polycarbonate, Polysulfone): Plastics offer a compromise between the visibility of glass and the durability of metal. They are more resistant to impact than glass and are lightweight and inexpensive. Polycarbonate is a common choice for general-purpose air or water applications, while polysulfone offers better chemical and temperature resistance. Still, their pressure and temperature ratings are modest, and they are susceptible to attack by certain organic solvents.

Metal (Stainless Steel, Hastelloy): When the application involves high pressures, high temperatures, or opaque and aggressive fluids, metal tubes are the only viable option. Stainless steel (typically 316 SS) is the workhorse, offering excellent strength and good general chemical resistance. For extremely corrosive fluids like wet chlorine or strong acids, more exotic alloys like Hastelloy may be required. Since the tube is opaque, these high-pressure variable area meters rely on a magnetic coupling between the internal float and an external indicator or transmitter.

The Float: The Heart of the Measurement

The float is the dynamic element of the meter. Its material must not only be compatible with the fluid but also have the correct density to provide an appropriate measurement range.

Float materials are chosen for both their chemical resistance and density:

- Glass or Sapphire Balls: Often used in small purgemeters for their chemical inertness and predictable shape.

- Stainless Steel (316 SS): A common, versatile choice offering a good balance of corrosion resistance and density.

- Plastics (PVC, PTFE): Used for their excellent chemical resistance, particularly in applications where metal ions would contaminate the process fluid (e.g., deionized water). Their low density makes them suitable for lower flow rate measurements.

- Tantalum, Hastelloy, Monel: These dense and highly corrosion-resistant materials are reserved for the most demanding applications involving aggressive chemicals where stainless steel would fail.

The final piece of the puzzle is the seals, or O-rings, which prevent leaks between the tube and the end fittings. Common materials like Buna-N are fine for general use, but Viton or Kalrez are often required for aggressive chemicals or high temperatures. A chemical compatibility chart is an indispensable tool in this stage of the selection process.

Check 5: Planning for Proper Installation and Orientation

A perfectly specified variable area flow meter can still provide wildly inaccurate results if it is installed incorrectly.

The Mandate of Vertical Mounting

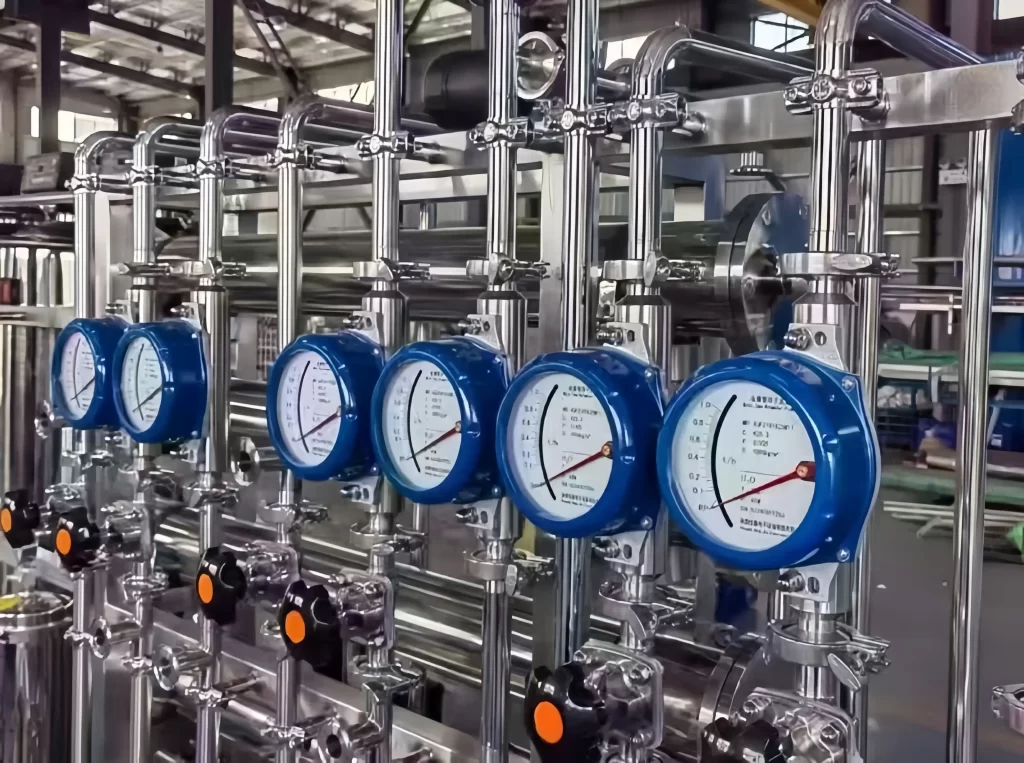

Metal tube rotameter flow meters must be installed vertically on a vibration-free pipe. The fluid must flow upwards through the flow meter, and the vertical alignment must be within 2°.

If the meter is tilted, a component of the float’s weight will be supported by the tube wall instead of the fluid flow. This reduces the amount of upward force required to lift the float, causing it to ride higher than it should and produce an erroneously high reading.

The degree of error is proportional to the angle of tilt. Some manufacturers even build a small bubble level into the meter’s housing to facilitate proper installation.

The Importance of Straight Pipe Runs

Fluid does not typically flow through a pipe in a perfectly uniform, well-behaved manner. Bends, valves, and reducers in the piping create turbulence and swirl in the flow stream. This non-uniform flow profile can cause the float in a rotameter to become unstable, oscillating or spinning in the tube.

To ensure a stable, well-developed flow profile enters the meter, it is standard practice to install a certain length of straight, unobstructed pipe directly upstream (and sometimes downstream) of the flow meter. A common rule of thumb is to have at least 10 pipe diameters of straight run before the meter inlet and 5 pipe diameters after the outlet.

For example, for a 1-inch pipe, you would need at least 10 inches of straight pipe leading into the meter. If a particularly disruptive element like a partially open valve or a pump outlet is located just upstream, a longer straight run may be necessary.

Managing Valves and System Control

The placement of control valves relative to the flow meter is also important. Whenever possible, the flow control valve should be placed downstream of the rotameter. Placing the valve upstream can create a jet of high-velocity fluid that impinges on the float, causing instability.

By placing the valve downstream, the meter operates at a more constant, higher inlet pressure, leading to more stable and reliable readings.

Check 6: Integrating with Your Control Systems

In many modern facilities, a flow meter is not just a local display for an operator to glance at; it is a sensor providing critical data to a larger control system.

A simple glass tube rotameter with a visual scale is a standalone device. When you need to transmit flow data to a programmable logic controller (PLC), a distributed control system (DCS), or a data logger, you must select a variable area flow meter equipped with an output signal.

From Mechanical Motion to Electronic Signal

For opaque metal tube rotameters, an output signal is a necessity, as the float is not visible. This is achieved through magnetic coupling. The float carries a set of powerful magnets. As the float moves up and down with the flow, its magnetic field moves with it. An external indicator, mounted to the outside of the tube, contains a follower magnet that tracks the float’s position, moving a pointer on a visual scale.

To generate an electronic signal, this mechanical follower is replaced with or supplemented by a transmitter. The transmitter uses a sensor—such as a Hall effect sensor or a magnetorestrictive sensor—to precisely detect the position of the float’s magnetic field without any physical contact. This positional information is then converted by the transmitter’s electronics into a standard industrial signal.

The Ubiquitous 4-20 mA Signal

The most common type of output signal in process instrumentation is the 4-20 milliamp (mA) analog current loop. This has been the industry standard for decades for good reason. In this system, the transmitter regulates a current that flows through a two-wire circuit, with 4 mA representing the lowest point of the measurement range (0% flow) and 20 mA representing the highest point (100% flow).

The 4-20 mA signal offers several advantages:

- Noise Immunity: Current signals are far less susceptible to electrical noise and interference over long cable runs than voltage signals.

- Live Zero: The use of 4 mA for zero flow allows the control system to distinguish between a true zero reading and a broken wire or failed transmitter (which would result in 0 mA).

- Loop Power: The transmitter can often be powered by the 4-20 mA signal itself, simplifying wiring.

When selecting a variable area flow meter with a transmitter, you are essentially buying a complete measurement system. You need to ensure its 4-20 mA output can be correctly scaled and integrated into your PLC or DCS input card.

Digital Communication and Smart Features

While 4-20 mA remains the workhorse, digital communication protocols are becoming more common. Protocols like HART (Highway Addressable Remote Transducer) superimpose a digital signal on top of the standard 4-20 mA loop. This allows for two-way communication with the transmitter. An operator can use a handheld communicator or a PC to remotely configure the meter’s range, diagnose problems, and access additional process variables without having to physically visit the instrument.

More advanced protocols like FOUNDATION Fieldbus or Profibus go a step further, creating a fully digital, multi-drop network where several instruments can communicate on the same pair of wires.

Check 7: Evaluating the Total Cost of Ownership

The final check in our selection process moves from the technical to the economic sphere. It is tempting to choose a flow meter based solely on its initial purchase price. However, this can be a shortsighted approach. A truly rational decision considers the total cost of ownership (TCO) over the entire lifecycle of the instrument.

TCO includes not just the upfront cost but also the costs of installation, maintenance, potential downtime, and eventual replacement. A cheaper meter that fails frequently or provides inaccurate data can end up being far more expensive in the long run.

The Initial Purchase Price Spectrum

The purchase price of a variable area flow meter varies dramatically based on its design and materials.

- Low End: Simple, small, plastic-bodied purgemeters used for regulating low flows of air or water can be purchased for under a hundred dollars.

- Mid-Range: Standard glass tube rotameters for general industrial use typically fall in the range of a few hundred to over a thousand dollars, depending on size, pressure ratings, and valve options.

- High End: Metal tube rotameters, especially those made from exotic alloys, equipped with 4-20 mA transmitters and digital communication protocols, represent the top of the range. These sophisticated instruments can cost several thousand dollars.

While it is wise to seek a competitive price, the cost should be weighed against the technical requirements. Choosing a plastic meter for an application that really demands stainless steel simply because it is cheaper is a recipe for failure.

Installation and Maintenance Costs

The cost of ownership begins to accumulate after the purchase. Installation costs can be significant, particularly if piping modifications are required to accommodate the necessary straight runs. A meter that is easy to install and commission saves labor costs.

Maintenance is another ongoing expense. The beauty of the basic variable area flow meter is its simplicity. With no moving parts other than the float, mechanical maintenance is minimal. The primary task is periodic cleaning. If the process fluid is dirty or prone to coating, the tube and float may need to be removed and cleaned to ensure the float can move freely and the scale (on a glass tube) is visible. A meter that is difficult to disassemble for cleaning will incur higher labor costs over its lifetime. Transmitters add a layer of complexity, though modern electronic devices are highly reliable. Calibration checks may be required periodically, which also represents a maintenance cost.

The Hidden Costs of Inaccuracy and Downtime

The most significant, yet often overlooked, costs are those associated with poor performance. If a flow meter provides inaccurate readings, it can lead to off-spec product, wasted raw materials, and inefficient process operation.

Imagine a batching process where an inaccurate meter consistently adds too much of an expensive ingredient. The cumulative cost of that wasted material can quickly dwarf the initial cost of a more accurate meter.

Even more costly is unplanned downtime. If a cheap, poorly specified meter fails, the entire process may have to be shut down for its repair or replacement. The lost production during this downtime can be astronomically expensive, far exceeding any initial savings on the hardware.

FAQ

More Flow Measurement Solutions

Selecting the right variable area flowmeter requires careful consideration. Analyze the characteristics of the process fluid, understand the ambient pressure and temperature conditions, and clearly define the specific flow range and accuracy requirements. This should gradually transition to a practical consideration of the product’s economic benefits.

Sino-Inst is a professional supplier of variable area flowmeters. Our flowmeters consistently provide accurate and reliable measurement data. We are a trusted partner in your process.

If you need to purchase a variable area flowmeter or have any technical questions, please feel free to contact us.

-1.jpg)