A high-temperature pressure sensor is an instrument that accurately measures the pressure of high-temperature media. It converts pressure into an electrical signal and maintains stable operation even at high media temperatures. Industries like steelmaking, chemicals, and petroleum are essential, as a failure could lead to production halts. Therefore, it is crucial.

Customized Case Sharing

A customer from Kuwait ordered an ultra-high-temperature pressure sensor from us, also known as a water-cooled pressure sensor. The specific specifications are as follows:

- Ultra-high-temperature pressure sensor

- Water-cooled

- 30 MPa gauge pressure

- Temperature: 1200°C

- Mounting thread: M20*1.5

- 4-20 mA signal output

- No local display

- Accuracy: ±0.5%

A customer from the United States ordered a high-temperature pressure sensor from us. The specific specifications are as follows:

- High temperature pressure transmitter

- Measurement medium: nitrogen

- Pressure: 1-50 psi

- Temperature: 900°C

- Signal output: 4-20 mA

- Local display

- 0.5″ NPT

Operating Principle

Both pressure sensors utilize the traditional diffused silicon principle. Based on the piezoresistive effect of single-crystal silicon, an elastic component is fabricated using advanced micro-electromechanical processing technology in a specific direction on the silicon wafer. Four force-sensitive resistors of equal resistance, fabricated using integrated circuit technology, are connected to form a pressure sensor. Wheatstone bridge. A constant voltage (current) is applied to the bridge. The measured pressure is transmitted losslessly to the silicon chip through the silicone oil sealed in the measuring diaphragm. The transmitter then outputs a voltage signal linearly proportional to the measured pressure. This voltage signal is then amplified and converted into a standard two-wire signal by electronic circuitry.

When measuring high-temperature media, sensor reliability and stability are critical factors in industrial applications. High temperatures not only affect sensor performance but can also shorten its service life. Therefore, sensor design for high-temperature environments is particularly important. The two pressure sensors have different heat dissipation designs.

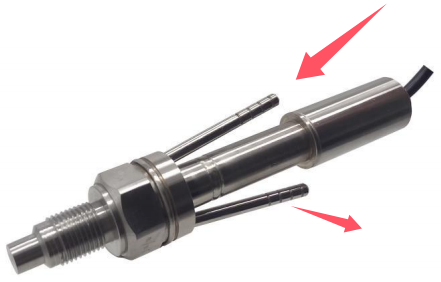

Water-cooled pressure sensors have cooling water channels in their housings. The circulating cooling water removes heat from the sensor’s internal electronics and diaphragm area, preventing them from accumulating in high-temperature environments. Overheating can cause failure. High-temperature pressure sensors, on the other hand, use heat sinks to cool the sensor, protecting critical components behind the sensor. In reality, only the heat sink and pressure inlet are subject to high temperatures.

Advantages

- Good sealing

- Multiple signal output options

- Accuracy up to 0.5%

- Customizable threads

- OEM support

Applications

- Aerospace and aerospace engine thrust testing

- High-temperature automated testing systems

- Internal combustion engine pressure control programming

- High-temperature boiler and combustion chamber monitoring

- Pressure monitoring of other high-temperature fluids

High-temperature And High-pressure Pressure Sensors

In practice, many customers encounter not only high temperatures but also high pressures. In the aerospace field, high-temperature and high-pressure operating environments are frequent, particularly in engines, thermal protection systems, and aircraft fuel systems. During oil and gas exploration, deep underground pressures are also a concern. In high-temperature and high-pressure environments.

Sino-Inst’s high-temperature pressure sensors can also be customized for high-pressure measurements. They accurately measure pressure changes under these complex conditions, providing real-time data for aircraft performance monitoring and control. They also provide critical data for oil and gas production in oil drilling and oil and gas well pressure testing. One of our customers once customized a pressure sensor capable of operating at 400°C and 300 MPa for high-temperature gas measurement. After our follow-up visit, the customer confirmed the excellent performance of our pressure sensor.

Integrated Temperature And Pressure Transmitter

With technological advancements and market changes, many applications, such as industrial process control and oil and gas transportation monitoring, require both pressure and temperature monitoring. Consequently, customer demand for sensors capable of multi-parameter measurement is increasing.

Thus, we developed We have released a temperature and pressure integrated transmitter that measures both pressure and temperature, consuming only the power of a single sensor. It features an integrated elastomer structure, eliminating leakage risks. It incorporates a highly reliable diffused silicon pressure sensor chip and a PT100 temperature sensor. The two outputs are independent of each other.

Our customer previously customized a temperature and pressure integrated transmitter with a pressure range of 40 MPa and a temperature range of 100°C. After receiving and using it, the customer was impressed by the excellent performance and found it very helpful.

More Solutions For Pressure Measurement

- Pressure Switch vs Sensor What You Need to Know

- Natural Gas Pressure Transmitters – Selection and Products

- Gas Pressure Measurement for Industrial Tanks and Pipelines

- Industrial Hydraulic Pressure Sensors – Top Guide

- Common Industrial Pressure Measuring Devices

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Case-Liquid Oxygen Pressure Measurement

- Understanding Digital Air Pressure Sensors: Why They Matter

- Everything You Need To Know About Electronic Pressure Transducers

- Customized Case: High Temperature and High Pressure Pressure Measurement -100MPa-700℃

- Featured Gauge Pressure Transmitters for Industrial Process Pressure Measurement

- What Are Diaphragm Seal Systems in Pressure Measurement? and Types

- Industrial Differential Pressure Sensors | Sino-Inst

- RS485 Pressure Sensors

- Water Level Pressure Transducers

- Differential Pressure Transmitters – Guide and Selection

- DP Transmitters for Filter Differential Pressure Monitoring

- 2 Wire-3 Wire-4 Wire Pressure Transducer Wiring Diagram

- Industrial Analog Pressure Transducers | 4-20mA, 0-5/10V DC

- Submersible Pressure Transducers for Liquid Pressure and Level Measurement

Summary: Sino-Inst has many years of experience in designing and manufacturing pressure sensors. We offer gauge, absolute, and differential pressure sensors. Ranges range from 7 kPa to 1000 MPa (vacuum capable), and materials include SS316L, titanium, tantalum, and Hastelloy C. The sensors are temperature-resistant from -252°C to 1200°C. Please contact our technicians to discuss your requirements and we will provide a customized solution.

-1.jpg)