Industrial liquid oxygen is a colorless and odorless liquid oxygen with low temperature and flammable properties. In the fields of petroleum, chemical industry, and medical treatment, liquid oxygen is widely used in the production process. Its leakage may cause serious harm to operators and equipment. Real-time monitoring of the pressure of liquid oxygen tanks and pipelines can detect abnormal conditions in time, which is of great significance for ensuring industrial safety.

Customized case sharing

Users from Germany selected the model and parameters on their own through our website:

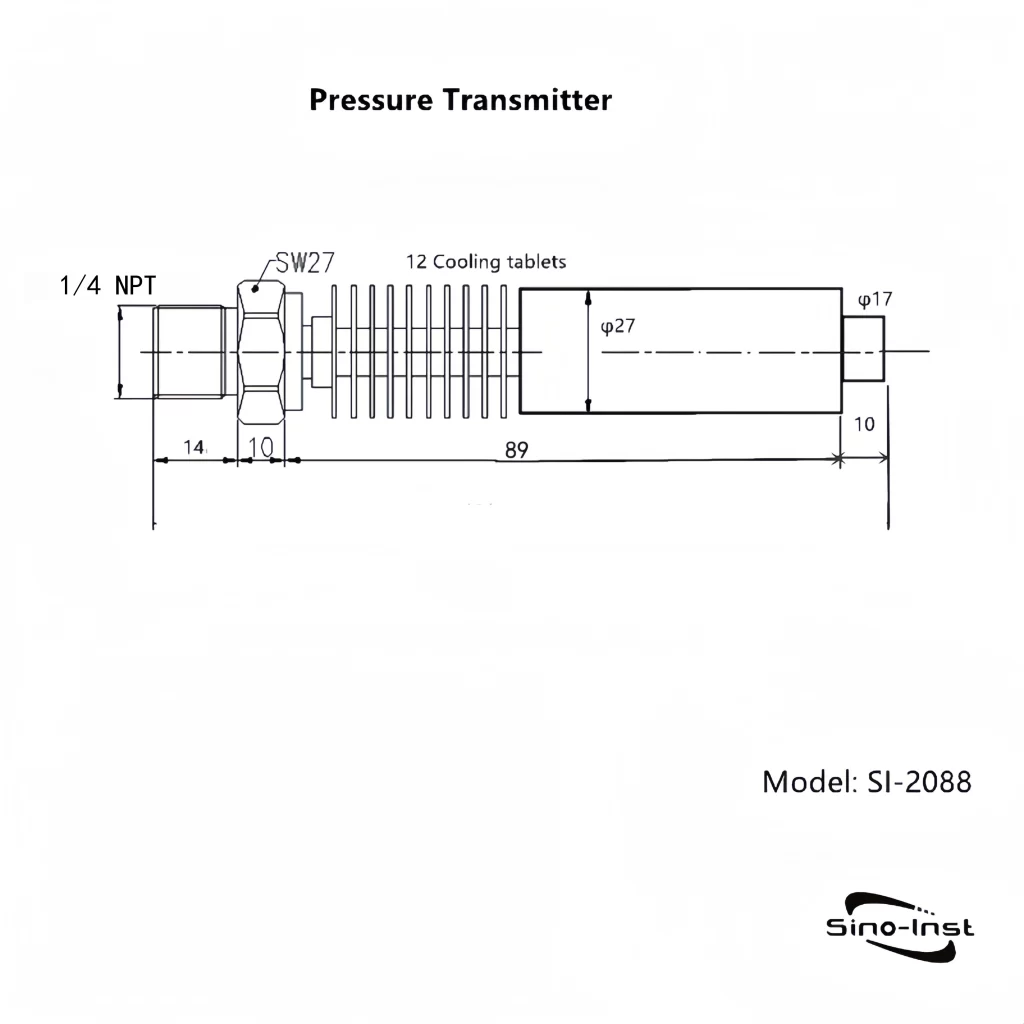

- Pressure transmitter

- Model: SI-2088

- Measurement medium: LIN or LOX.

- Pressure range: 0-30bar gauge pressure

- Temperature: -200℃

- 24VDC

- 4-20mA two-wire system

- 1/4″NPT thread installation

- No local display

Application of liquid oxygen pressure sensor in industry

Metal processing industry: In the process of cutting metal materials, liquid oxygen is usually mixed with fuel gas. The high temperature generated by the mixed gas during combustion can quickly melt the metal. Compared with traditional cutting methods, the process of using liquid oxygen not only speeds up the operation process, but also reduces material loss.

Chemical industry: Liquid oxygen is an oxidant in many chemical reactions. At the same time, liquid oxygen is also the main oxidant for rocket fuel in the aerospace field. It can release high energy and provide reliable power guarantee for the launch of spacecraft.

Medical field: In the medical industry, liquid oxygen will be converted into gaseous oxygen, which is widely used in the oxygen supply system of hospitals.

Environmental protection industry: Liquid oxygen controls industrial waste gas emissions by participating in the oxidation reaction of harmful gases. Liquid oxygen can help generate ozone in sewage treatment and participate in water disinfection and purification.

Advantages

- High precision

- High sensitivity

- Wide temperature range and good temperature performance

- High reliability and stability

- Good compatibility and corrosion resistance

Working Principle

Based on the piezoresistive effect of single crystal silicon, an elastic component is made in a certain direction on the silicon wafer using advanced micro-electromechanical processing technology, and four force-sensitive resistors with equal resistance are made using integrated circuit technology at the appropriate position, connected to form a Wheatstone bridge.

A constant voltage (current) is applied to the bridge, and the measured pressure is transmitted to the silicon wafer without loss through the silicone oil sealed in the measuring diaphragm box. The transmitter outputs a voltage signal that is linearly proportional to the pressure to be measured, and then the voltage signal is amplified and converted into a two-wire standard signal through the electronic circuit.

1. Pressure-deformation conversion: When the pressure of the measured medium is applied to the diaphragm of the sensor, the diaphragm will produce a small displacement due to the force, and this displacement is proportional to the medium pressure. For example, taking a stainless steel or ceramic diaphragm as an example, under the action of pressure, the diaphragm undergoes elastic deformation, and then the deformation is transmitted to the diffused silicon chip through silicone oil.

2. Piezoresistive effect: The working principle of the diffused silicon chip is based on the piezoresistive effect. There are four Wheatstone bridge structures inside the chip. When the micro-displacement of the diaphragm is transmitted to the chip, the chip generates stress, which in turn causes the resistance value to change, and the change in resistance value is proportional to the pressure on the diaphragm.

3. Signal conversion and output: The bridge is unbalanced due to the change in resistance value, thereby outputting an electrical signal proportional to the pressure. This electrical signal will be processed by the signal conditioning circuit inside the sensor and finally converted into a common standard measurement signal, which is convenient for subsequent data collection and processing.

More Pressure Measurement Solutions

- Pressure Transducer Troubleshooting: Expert Insights & Tips

- Fluid Pressure Guide: Static Pressure Vs. Dynamic Pressure Vs. Total Pressure

- Steam Pressure Sensor/transducer for Industrial Steam Measurement

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

Sino-Inst’s pressure transmitters are widely used in various industries and have been exported to the United States, the United Kingdom, Germany, Singapore, Malaysia, Nigeria and other countries, and have been highly praised by customers. Our pressure transmitters support customization. We can accept low temperatures as low as -252℃, high temperatures up to 1200℃, and high pressures up to 1000MPa. If you have any questions or needs about pressure transmitters, please contact us.

-1.jpg)