In food production, pharmaceutical industry, chemical industry and other processes, many fluid flow measurements require hygienic and aseptic processes. Non-Contact Flow Meters have become an important choice.

Non-Contact Flow Meters have no contact with the fluid and do not require cutting or modification of the pipeline. Suitable for all applications with strict hygiene requirements.

This blog post will explore the working principle, types, applications, advantages and challenges of non-contact flow meters. Help you choose the right Non-Contact Flow Meters.

What is a non-contact flow meter?

The non-contact flow meter is a kind of flow metering device that does not need to insert, pipe penetration or cut any mechanical parts through the pipe or extend into the flow system to accurately measure the liquid flow rate in the closed pipe.

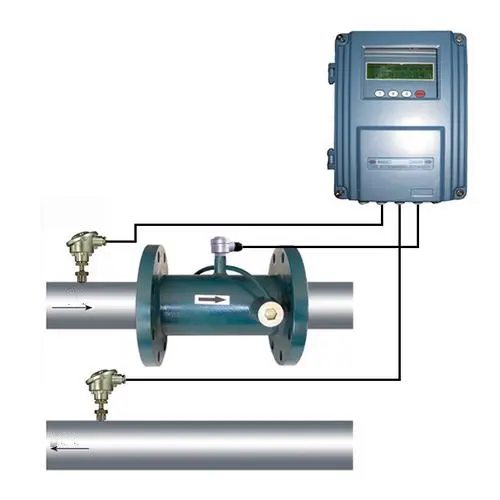

Non-contact flow meters can be installed on the outer wall of the pipeline to achieve flow measurement without pipe or flow interruption. And there is no pressure loss for its non intrusive flow meter sensor. Clamp on ultrasonic flow meter realizes the non-contact measurement of the liquid flow rate.

Non-contact flow meter technology & ultrasonic flow meter types

Non-contact flow meter uses ultrasonic technology to measure the volume flow by detecting the effect of the ultrasonic beam (or ultrasonic pulse) when the fluid is flowing.

When the sound wave propagates in the fluid, the speed of the sound wave will increase in the downstream direction and decrease in the counter current direction. The same propagation distance will have different propagation times.

Ultrasonic flow meter types

According to the ultrasonic liquid flow meter, there are: transit time flow meter; Doppler flow meter.

Transit-time Ultrasonic Flow Meters: These meters work by measuring the time it takes for sound waves to travel downstream and upstream in the pipe. The difference in time between these two measurements is used to calculate the flow rate.

Doppler Ultrasonic Flow Meters: These meters use the Doppler effect, where the frequency of the reflected sound waves changes based on the velocity of the fluid. This change in frequency is then used to calculate the flow rate.

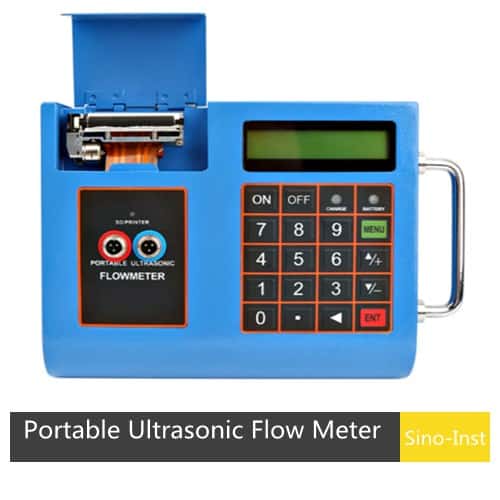

According to the structure of ultrasonic flow meter: panel-mounted, wall-mounted, integrated, portable flow meters, handheld flow meters, alignment rail transducers, clamp-on flow meter, insertion ultrasonic flow meters , etc.

Non-contact flow meter advantages

Disadvantages of non contact flow meter

- Transit time ultrasonic flow meter can only be used to clean liquids and cannot measure liquids with suspended particles and bubbles exceeding a certain range.

- Although Doppler ultrasonic flow meter can measure liquids with impurities. But the proportion of impurities cannot be too high. And the price of Doppler ultrasonic flow meter is usually more expensive.

- Non contact flow meters with clamp on transducers cannot be used for pipelines with thick lining or thick fouling, stainless steel 316 or pipelines with severe corrosion.

Specifications of non contact flow meters

- Good stability and high accuracy: Linearity is better than 0.5%, repeatability is better than 0.2%, measurement accuracy is better than ±1%;

- Wide measuring range, various flow probe options: Different types of ultrasonic flow sensors can be used to measure the flow rate of pipes with a diameter of DN6~DN200~ DN6000mm.

- Non contact flow detects velocity range: -10m/s~+10m/s.

- Small and light non-contact flow meters: easy for transportation and carry on, also easy to install the clamp on transducers

- With keys for easy configurations and easy settings.

Applications of Non-Contact Flow Meters

Oil and Gas Industry: Used for monitoring crude oil flow, refined petroleum products, and gas pipelines without risking leaks or contamination.

Water and Wastewater Management: Deployed in treatment plants and distribution systems to measure water flow in large pipes and open channels.

Chemical Processing: Ideal for handling corrosive chemicals and hazardous materials without exposing sensors to harsh environments.

Food and Beverage Industry: Ensures hygiene by measuring the flow of liquids such as milk, juices, and other beverages without direct contact.

Pharmaceutical Industry: Supports the precision required in drug manufacturing and sterile processing.

Future Trends in Non-Contact Flow Measurement

With advancements in sensor technology and data processing, non-contact flow meters are expected to become even more accurate, reliable, and cost-effective. Emerging trends include:

- Integration with IoT and AI

- Improved Signal Processing

- Miniaturization and Portability

- Improve the compatibility of complex media.

More Flow Measurement Solutions

- Relationship Between Pressure And Flow Rate: Key Insights

- High Accuracy Flow Meters: Technology, Applications, And Benefits

- Right Flow Meter For Molasses

- Mechnical & Digital Kerosene Flow Meters

- Understanding Asphalt And Bitumen Flow Meters

- Liquid Flow Controller-Flow Meter | For Process Liquids

- Extreme Temperature Flow Meters: Accurate Flow Measurement In Harsh Environments

- Inline Thermal Mass Flow Meters | Sino-Inst

Non-contact flow meters offer a highly impelling solution for industries requiring accurate, contamination-free, and low-maintenance flow measurement. With a range of technologies available, selecting the right meter depends on fluid properties, application requirements, and budget considerations. As technology continues to evolve, non-contact flow meters will play an increasingly vital role in industrial automation and process optimization.

Sino-Inst is a Professional flow meter manufacturer and supplier. Our Ultrasonic flow meters are popular in the market. Expert team of our company is always available for customers with best flow measurement solutions.

-1.jpg)