Flow meters measure the volume or mass of liquid, gas, or steam moving through a piping system. There are many different flow meter technologies, and each delivers different accuracy.

The accuracy requirements for a flow meter depend a great deal on the exact application. High accuracy flow meters have become vital tools for industries where precision is paramount. This blog post explores the technology behind high accuracy flow meters, their applications, benefits, and key considerations for selecting the right meter for specific needs.

What is Flow Meter Accuracy?

Accuracy is the most common term and is sometimes used incorrectly. Accuracy is how close your instrument comes to giving you the exact value that exists in the process at that moment. It is commonly expressed as a value, or margin of error, above or below the reading that the instrument is showing.

For example, let’s say that your flow meter is showing a result of 1 GPM, with an accuracy of ± 10%. The exact value of the flow in the meter is more than likely not exactly 1 GPM because of the inherent deviation. More than likely, the actual flow rate is somewhere in between 0.9 GPM and 1.1 GPM. This is accuracy. When accounted for, in relation to the value being expressed by the meter, it gives you the range that the actual value falls between.

Operative Elements of a Flow Meter: Components that decide the accuracy of a flow meter

Operative Elements of a Flow Meter: Components that decide the accuracy of a flow meter

- Primary Sensing Element: Measures the flow rate through a physical or electronic mechanism.

- Transmitter: Converts the sensed data into readable measurements.

- Processing Unit: Applies calibration factors and compensations for temperature, pressure, and fluid properties.

- Output Interface: Displays data or transmits it to control systems.

Different types of flow meters utilize various measurement principles to achieve high accuracy. Let’s explore some of the most commonly used high accuracy flow meter types.

Types of High Accuracy Flow Meters

Key Types of High Accuracy Liquid Flow Meters and Their Applications

Coriolis Flow Meters: Coriolis flow meters use the Coriolis effect to measure mass flow directly. They consist of vibrating tubes that twist in response to fluid movement, and sensors detect these changes to determine the flow rate. These meters offer exceptional accuracy (±0.1% or better) and are widely used in oil and gas, pharmaceuticals, and food industries.

Electromagnetic Flow Meters: Magameters use electromagnetic induction to measure flow in conductive fluids. These meters are highly accurate (±0.2% or better) and widely used in water treatment, chemical processing, and beverage industries.

Liquid turbine flow meter: Turbine flow meters measure flow by detecting the rotation of a turbine within the fluid stream. These meters offer high accuracy (±0.5% or better) when properly calibrated and used with clean, low-viscosity fluids.

Gear Flow Meters: The cylindrical gear transmitter is processed with high precision and precisely installed. The rotation of the gear is scanned contactless, and each tooth generates a pulse with very high resolution. The cylindrical gear transmitter can measure very small flow rates and quantitatively measure small volumes of liquid. The accuracy can reach 0.5%.

Ultrasonic Flow Meters: Ultrasonic flow meters measure flow by analyzing sound waves traveling through the fluid. There are two primary types: transit-time and Doppler. Transit-time ultrasonic meters, in particular, provide high accuracy (±1% or better) by measuring the time difference between upstream and downstream signals.

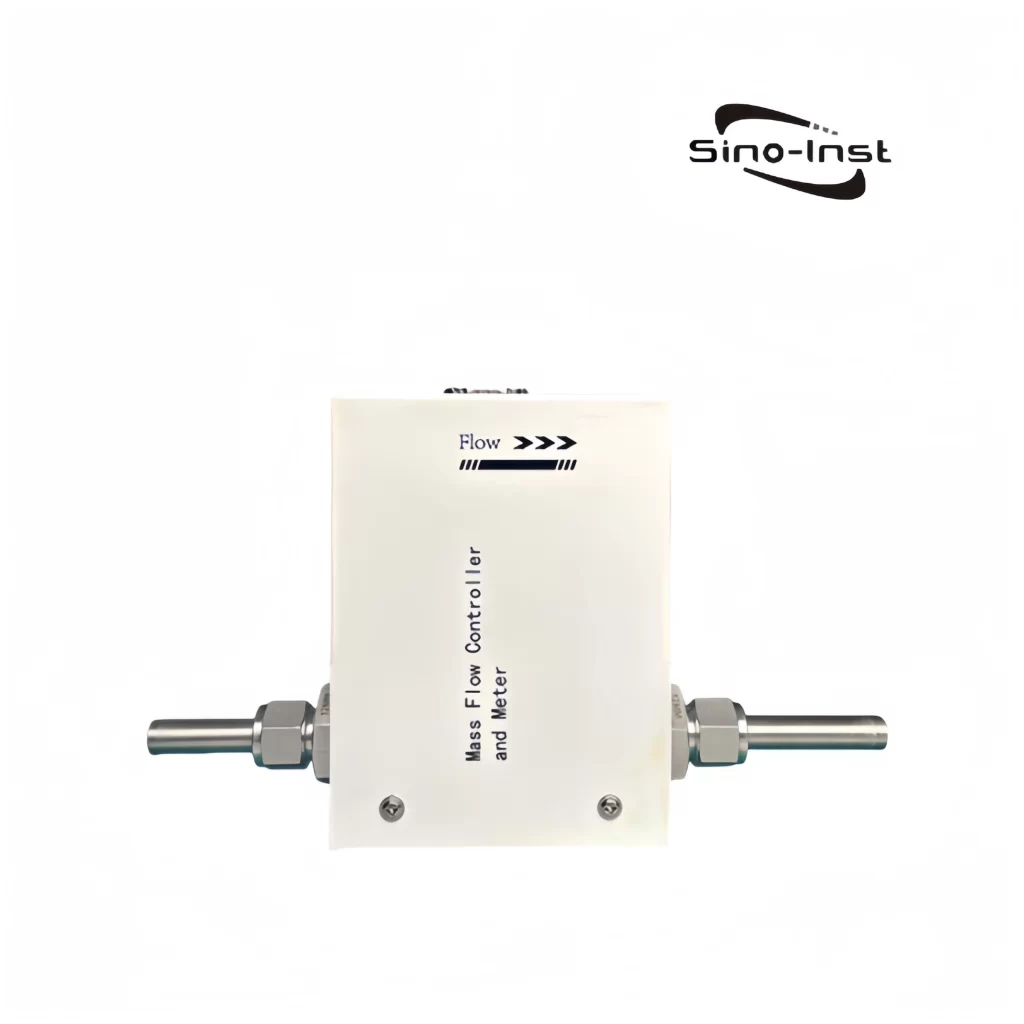

Key Types of High Accuracy Gas Flow Meters and their applications

Coriolis Mass Flow Meters: These meters are capable of measuring both mass flow and density, making them fit for a variety of gas types, including natural gas, nitrogen, and oxygen. Common accuracy 0.1%R.

Thermal Mass Flow Meters: Thermal mass flow meters are also widely used in gas flow measurement. These meters are ideal for measuring gases such as natural gas, compressed air, and oxygen. Common accuracy 1.5%R.

Vortex flow meter: Vortex flow meter can measure a variety of gases, including air, nitrogen, oxygen, carbon dioxide, hydrogen and natural gas. It also includes special gases such as hydrogen chloride and ammonia, providing high-precision flow control. Common accuracy 1.0%R, 1.5 %R. SI-3301 and SI-3301 are examples of Gas Vortex Flow Meters.

Benefits of High Accuracy Flow Meters

- Better Process Efficiency

Accurate flow measurement allows industries to optimize their processes, reducing waste and improving overall efficiency. - Cost Savings

Precise measurement minimizes product loss, reduces overages, and ensures proper billing, resulting in significant cost savings. - Compliance with Industry Regulations

Many industries must adhere to strict regulatory requirements regarding flow measurement. High accuracy flow meters help meet compliance standards and avoid legal or financial penalties. - Enhanced Safety

Accurate flow measurement helps detect leaks, pressure anomalies, and hazardous conditions, reducing risks associated with fluid handling.

Choosing the Right High Accuracy Flow Meter

- Fluid Type: Some meters work best with specific fluids (e.g., magmeters for conductive liquids, Coriolis for mass flow measurement).

- Flow Range: Ensure the meter’s operating range matches the expected flow rates.

- Accuracy Requirements: Select a meter with the required precision level.

- Installation Environment: Consider temperature, pressure, and space constraints.

- Maintenance Needs: Choose a meter with minimal maintenance requirements if operational downtime is a concern.

More Flow Measurement Solutions

- Right Flow Meter For Molasses

- Mechnical & Digital Kerosene Flow Meters

- Understanding Asphalt And Bitumen Flow Meters

- Extreme Temperature Flow Meters: Accurate Flow Measurement In Harsh Environments

- Inline Thermal Mass Flow Meters | Sino-Inst

- Mass Flow Meter Vs Magnetic Flow Meter

- Liquid Mass Flow Meters And Its Significance

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

High accuracy flow meters are essential tools for industries that require precise fluid measurement. Whether used in oil and gas, chemical processing, or food production, these meters offer unmatched reliability, efficiency, and cost savings.

By understanding the different types of high accuracy flow meters and their applications, industries can make informed decisions when selecting the right meter for their needs. Investing in high accuracy flow measurement technology ultimately leads to improved operations, regulatory compliance, and better financial outcomes.

Sino-Inst has been providing lots of high accuracy flow meter solutions with its outstanding expert team, which helps customers to choose the best flow meter as per their requirements.

-1.jpg)