As two common types of installation processes, vertical and horizontal flow meters have their own unique structure and performance advantages.

Although most applications are horizontally oriented, mounting the meter vertically actually offers some advantages. Based on relevant information, this blog post will go deeply into a comparative analysis of vertical and horizontal flow meters.

Basic concept of Vertical Flow Meter and Horizontal Flow Meter

The difference between vertical and horizontal flow meters is largely based on the orientation of the installation of the flow measurement device. This orientation can influence the performance, maintenance, and accuracy of the meter, as well as the type of fluids being measured.

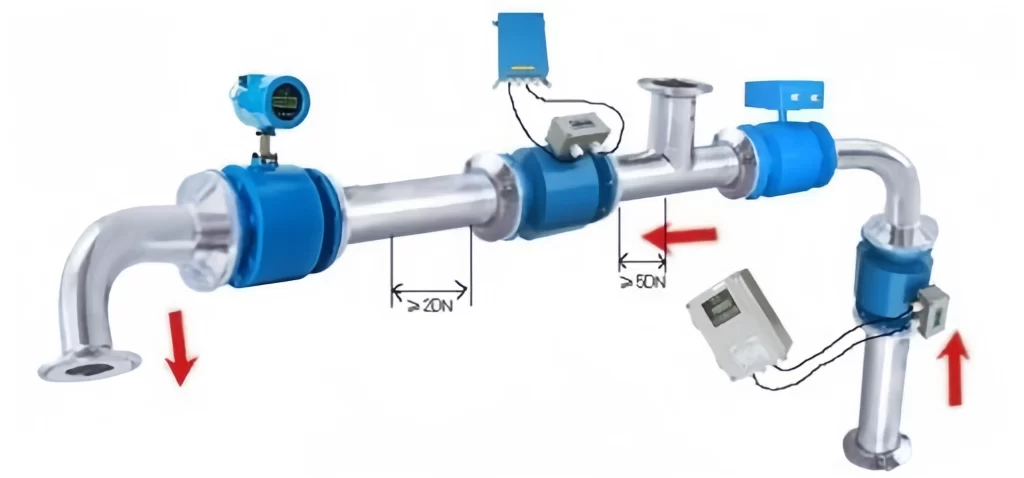

The axial arrangement of vertical flow meters enables them to achieve high flow rates in a small footprint, especially for applications that require a high flow rate and have a limited footprint. During the measurement process, it has little impact on the surroundings, has higher accuracy, and can accurately measure the flow. When installed vertically, the installation position should be below the pipeline to ensure that the medium flows normally into the interior of the flow meter.

Horizontal flow meters, on the other hand, are horizontally mounted on the ground and are characterized by good stability and ease of maintenance. The axial arrangement of horizontal flow meters allows them to smoothly handle larger flows and highly viscous liquids, making them suitable for applications requiring high stability and easy maintenance.

Comparative table of analysis of Vertical and Horizontal Flow Meters

| Attributes | Vertical Flow Meters | Horizontal Flow Meters |

| Space efficiency | Employing a vertical shaft design, vertical flow meters occupy a small footprint and are typically installed on top or next to storage tanks in areas with limited space. | Utilizing a horizontal shaft design, horizontal flow meters require more space but offer good stability and ease of maintenance. |

| Fluid types | Vertical flow meters tend to perform better when measuring high-viscosity fluids. The fluid’s gravity-assisted movement helps maintain a steady flow and reduces the risk of clogging or inaccuracies in measurement. | Horizontal Flow Meters perform well when measuring low-viscosity fluids (like water, gases, and oils), where the flow remains consistent and easily measurable. However, they may be less suitable for highly viscous or slurry-based fluids, as the movement can become erratic and lead to measurement errors. |

| Efficiencies | Similar efficiencies, generally ranging from 70% to 80%. | Similar efficiencies, generally ranging from 70% to 80%. |

| Flow Rates | Vertical flow meters typically have smaller flow rates, typically not exceeding 100 cubic meters per hour. | whereas horizontal flow meters can handle flow rates of several thousand cubic meters per hour. |

| Risk of Air Pockets | Due to the orientation, horizontal flow meters have an increased risk of air pockets or vapor lock. This can sometimes distort readings in horizontal flow meters. | Due to the orientation, horizontal flow meters have an increased risk of air pockets or vapour lock. This can sometimes distort readings in horizontal flow meters. |

| Cost-Effectiveness | Due to the orientation and setup, Vertical flow meters are costly. | In most cases, horizontal flow meters are more commonly used in industrial settings because they are easier to install in straight runs of piping without the need for special considerations related to gravity or orientation. It is cost effective. |

| Application fields | Suitable for applications that require high head and have limited space, such as high-rise building water supply systems and deep well water treatment. | Suitable for applications that require handling large flow rates such as chemical manufacturing and wastewater treatment. |

Relationship and selection of vertical and horizontal Flow Meters

When choosing between vertical and horizontal Flow Meters, several factors need to be considered, including application scenarios, fluid properties, installation space, and maintenance requirements.

Vertical Flow Meters are suitable for applications that require high head and space-saving, while horizontal Flow Meters are suitable for environments that need to handle high flow rates and highly viscous fluids.

In some cases, vertical flow meters are a must for gravity-driven systems, such as in wastewater treatment plants, where gravity naturally assists the flow. Vertical orientation helps achieve better flow dynamics, especially in these low-pressure environments.

Horizontal flow meters are ideal for measuring fluids that need to flow in a controlled manner under constant pressure. Because fluids in horizontal installations do not benefit from gravity, the flow must be powered, often using pumps.

If we consider the application areas of both flow meters, horizontal flow meters are used in a wide range of applications where space is less of a concern and the pipeline is oriented horizontally. This makes them highly versatile and easy to implement across various industries.

An example to understand the Vertical and Horizontal Flow Meter setups: Ultrasonic Clamp-on Flow Meter

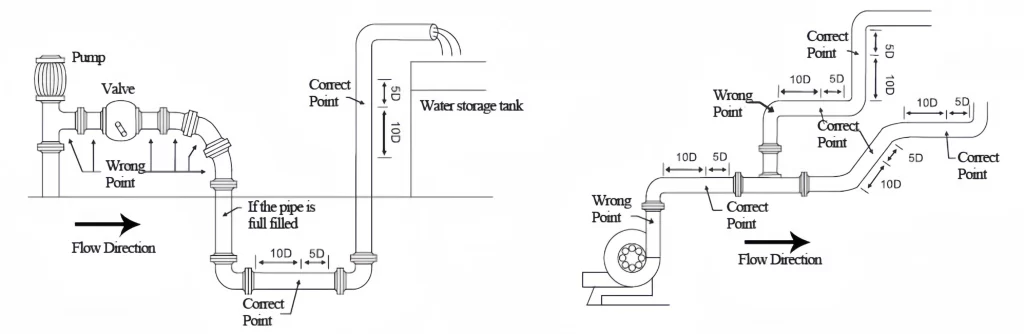

Ultrasonic Clamp-on Flow Meter can certainly be installed in both Vertical and Horizontal setup, but it’s important to consider where air collects so you can avoid any issues.

Vertical installation can be the best case or worst case for collecting air. The best case scenario is when flow is going upwards, i.e. flowing from the bottom to the top of the pipe. In this case, you are certain that the pipe is completely full of liquid so the ultrasound will transfer well.

In horizontal installation, air will collect at the top of the pipe, and sediment will collect at the bottom of the pipe. So, it is best to avoid installing the flow meter where the ultrasound will travel through the top or bottom of the pipe. Instead, rotate the flow meter off to the side of the pipe where the sound will travel through the pipe and fluid.

Since we cannot see inside the pipe, we should choose to install the flow meter where we can be most certain that the ultrasound can transmit through the fluid.

More Flow Measurement Solutions

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

Each type of flow meter offers unique benefits depending on the application. So it’s crucial to assess the needs of your specific system before making a decision. Whether you’re working in the food industry, oil and gas, HVAC, or chemical manufacturing, understanding the strengths of both vertical and horizontal flow meters will help you achieve more accurate and reliable measurements, improving system efficiency and reducing costs over time.

In summary, the choice between vertical and horizontal flow meters should always be guided by the specific needs of the fluid system, the environmental conditions, and the operational requirements of the application.

As an industry leader, Sino-Inst, with its excellent technology and high-quality service, is able to provide customers with optimal solutions. These best flow meter solutions of our company will definitely contribute to promoting the development of Flow Meter technology to its height.

-1.jpg)