Proper lubrication is indispensable for maintaining optimal performance of industrial instrumentation and heavy-duty equipment. Both under-lubrication and over-lubrication is critical. Grease and Lube Flow Meters ensure that lubricants are applied correctly.

The Grease And Lube Flow Meters use a rotating oval gear concept with encapsulated magnets to provide a pulsed output that corresponds volumetrically to the flow through the flow meter.

In this discussion, we will delve into the various types of grease and lube flow meters.

The Importance of Accurate Grease Flow Measurement

Grease and lubrication systems are integral to reducing friction and wear in machinery. Accurate flow measurement is paramount. It enables businesses to monitor consumption, track efficiency, and detect any deviations that could indicate leaks or equipment malfunction.

With precise measurements, companies can optimize their processes, reduce waste, and ensure the smooth operation of critical machinery. Here to summarize the importance of Accurate Grease Flow measurement:

- Better Performance

- Cost-Efficiency

- Improved Equipment Life

How Grease Flow Meters Work: Different types of Grease Flow Meters

Grease flow meters are typically designed to handle the thicker consistency of grease compared to liquid lubricants. This Flow Meter is suited to installation in critical lubrication points that typically are distinguished by relatively low flow and high pressure.

There are several types of flow meters used for this purpose, and each type works differently depending on the application. Common types of grease flow meters include:

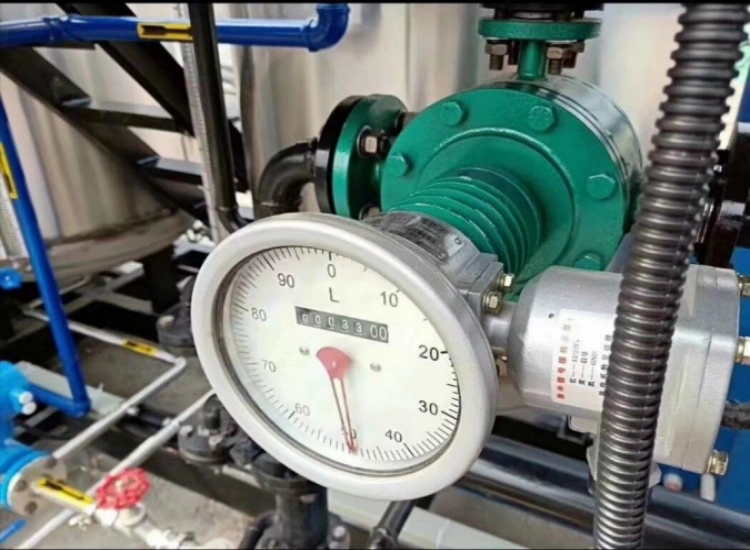

Oval gear flow meter

It is a kind of positive displacement oil flow meter. It can take high-viscosity grease measurements (max viscosity 2000 cp), and a max temperature of 200 °C. An oval gear flow meter can be made into a mechanical oil flow meter without any power supply. It can also equipped with a flow transmitter with pulse or 4-20mA output.

Turbine Flow Meters

In these meters, the flow of grease causes a turbine to spin. The speed of the turbine’s rotation correlates directly with the flow rate, which is then measured and converted into a readable output.

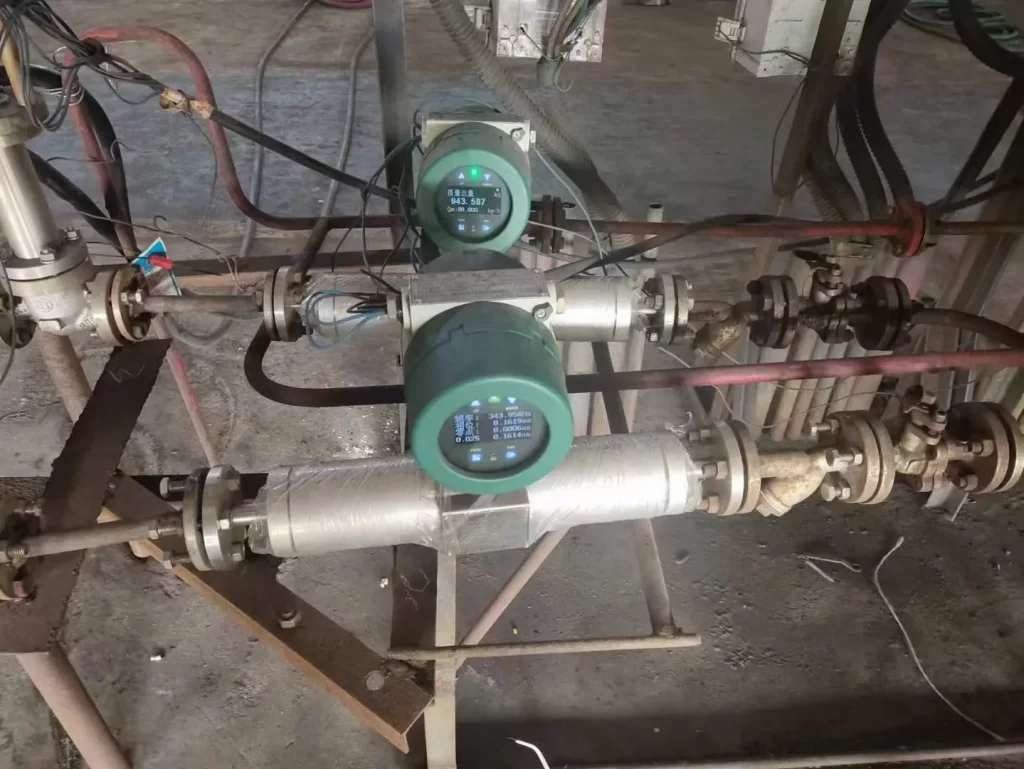

Coriolis mass flow meter

Coriolis flow meter is used to measure grease when high accuracy is needed. It is a kind of advanced flow metering device and a direct measure of oil mass flow. It can measure extremely viscous oil mass flow. So, perfect for Grease flow measurement. However, the Coriolis flow meter is expensive compared to other common types of oil flow meters.

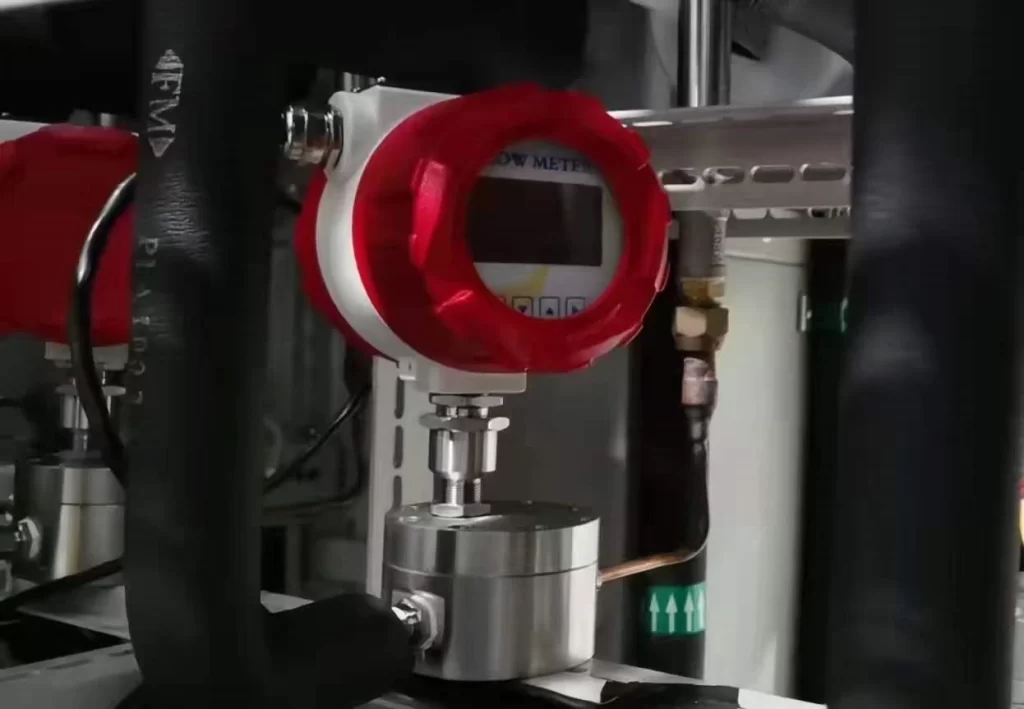

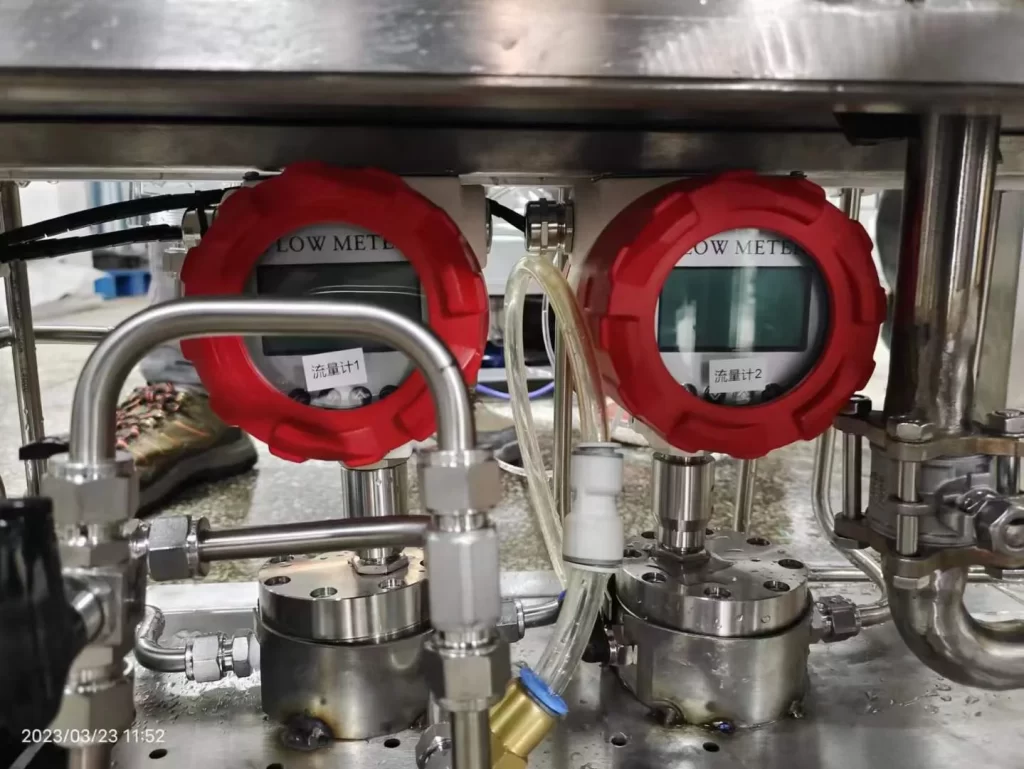

Digital Grease Flow Meters and their special features

A digital grease flow meter is an advanced version of the traditional mechanical grease flow meter. Digital grease flow meters often offer additional features such as:

I.Real-Time Monitoring

II.Data Logging

III.Accuracy and Calibration

IV.Alarms and Alerts

Lube Flow Meter: How it is different from Grease Flow Meters

A lube flow meter is similar to a grease flow meter but designed for use with oils and other lubricants, which have flow characteristics different from grease. These meters are used in automotive, industrial, and marine applications where oil or other lubricants need to be measured and dispensed accurately. Lube flow meters are often designed to handle thinner fluids than grease, but the principles behind their operation are the same.

While grease flow meters are used primarily for thicker lubricants, a lube flow meter can handle a broader range of fluids, including oils, coolants, and hydraulic fluids.

Grease Pump Flow Meter

A grease pump flow meter is a specific type of flow meter installed within a grease pump system to measure the exact amount of grease being pumped into the lubrication points of equipment. Grease pumps are often used in centralized lubrication systems, where they ensure that multiple components of a machine or piece of equipment receive the necessary amount of lubricant.

Grease pump flow meters help improve the efficiency of the lubrication system by:

- Ensuring Proper Lubrication Distribution

- Preventing Overuse of Grease

- Integration with Automated Systems

Common Troubleshooting and Calibration Issues

Even with proper installation and maintenance, Grease and Lube flow meters may encounter occasional issues that require troubleshooting.

Common problems include sensor drift, clogging, electrical interference, or mechanical wear. It is essential to have a comprehensive troubleshooting plan in place to identify and rectify these issues promptly.

Additionally, regular calibration is crucial to maintaining the accuracy and reliability of oil flow meters. Calibration ensures that the meter produces accurate measurements and provides traceability to recognized standards.

More Flow Measurement Solutions

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

- An All-inclusive Guide on Crude Oil Measurement

- Importance of Digital Fuel Flow Meters and Fuel Oil Flow Meters in Modern-day Industrial Applications

- Mechanical Oil Flow Meter vs Digital

Selecting the best flow meter for your application requires careful consideration of various factors. Accurate flow measurement is vital for optimizing efficiency, controlling costs, and ensuring the smooth operation of machinery.

In the end, investing in grease and lube flow meters can pay off by reducing downtime, minimizing damage to machinery, and lowering overall operating costs. Most importantly, it can help to extend the lifespan of your equipment. Unique Positive Displacement Flow Meters, Z Series Straight Tube Coriolis Liquid Mass Flow Meters, T Series Coriolis Mass Flow Meters top the list of Grease and Lube Flow Meters from Sino-Inst.

-1.jpg)