Flow measurement is a captious aspect of many industrial and scientific processes. Assuring fine control and monitoring of fluid flow enhances efficiency, quality, and safety.

While a rotameter is a type of flow meter, there are key differences that set it apart from other types. This blog will explore these differences, their working principles, and applications to help you understand which might be the better choice for your needs.

What is a Flow Meter?

A ‘flow meter’ is a device used to measure the rate at which a fluid (liquid or gas) flows through a pipe or channel. The measurement can be volumetric (e.g., liters per second) or mass-based (e.g., kilograms per hour), depending on the type of meter used.

Is a rotameter a flow meter?

Yes, a rotameter is a commonly used variable area flow meter that measures the volumetric flow rate of liquids and gases.bThe flow measurement technique is implemented by a free-moving float that is balanced in a tapered tube.

Rotameter type flow meters are referred to by a number of names including rotameter, variable area flow meters, and float-type flow meters.

Variable area rotameter technology has been around for more than 100 years. This type of flow meter is among the most commonly sold and installed flow meters in the world.

Rotameters can be used to measure the flow rate of either gases or liquids. Different rotameters for liquids can handle media of different viscosities like water or oil. They are not suitable for steam measurement.

They are comprised of a few simple parts: a tube (usually made of glass or plastic and sometimes protected by a surrounding metal housing), a float (usually metal), a scale (printed on the flow tube), fittings for inline installation, and optional outputs or switches for flow control.

Read more about:

- Metal Tube Rotameter: Working Principle and Applications

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

What is the Difference between a Rotameter and a Flow Meter?

Rotameter flow technology is such a long standing, familiar, and popular flow meter technology type that for some it is used as a substitute word for all flow meters in general.

This, however, is in error as rotameter flow meter technology is just one of many flow meter technology types. So, in essence, all rotameters are flow meters, but not all flow meters are rotameters.

What is a Rotameter Used For?

A rotameter is used to measure the rate of liquid or gas flowing through a system of pipes at any given time. They provide a constant flow rate measurement and can also offer optional switching capabilities to control the flow in a system or process.

How Do Rotameters Work?

The rotameter principle of operation is a mechanical means of flow measurement. They measure flow using a float that is able to move freely up and down within the flow tube.

The buoyancy force acting on the float, the flow resistance, and the weight of the float itself are all in equilibrium. This position of equilibrium provides the flow rate by referencing the top of the float against the scale printed on the flow tube.

Other existing Types of flow meters

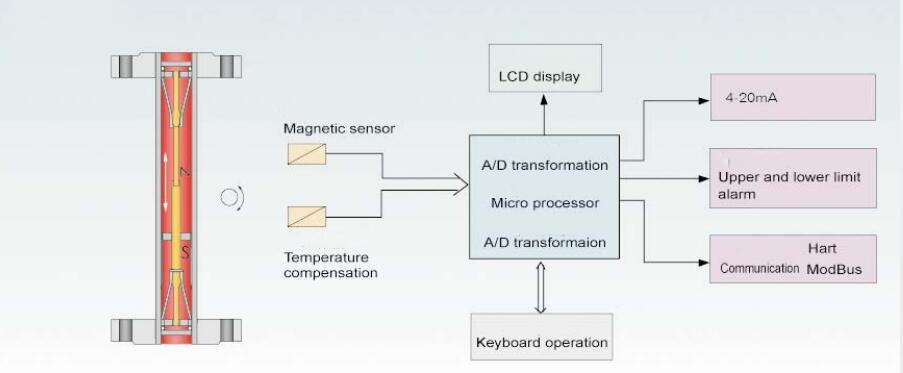

- Electromagnetic Flow Meters

Perfect for conductive liquids, they operate based on Faraday’s law of electromagnetic induction. - Ultrasonic Flow Meters

These use sound waves to measure flow and are commonly applied in non-invasive settings. - Turbine Flow Meters

These measure flow by detecting the rotation of a turbine placed in the path of the fluid. - Vortex flowmeter

Vortex flowmeter is widely used for flow measurement of gas, liquid and steam. It can be configured with integrated temperature and pressure compensation. - Coriolis Flow Meters

Renowned for precision, these measure mass flow and are used in demanding applications. - Volumetric Flow Meter

Volumetric flow meter is suitable for volume flow measurement of high viscosity media and oil media. It can be configured as a mechanical type. - Differential Pressure Flow Meter

Differential Pressure Flow Meters are mostly used for flow measurement under special working conditions. For example, large diameter, ultra-high temperature, etc.

Rotameter vs Flow Meter

| Attributes | Rotameter | Other flow meters |

| Working Principle | Rotameter operates on a variable area principle. The float moves to balance the upward force of the fluid and the gravitational force. The float’s position provides a direct visual indication of flow rate. | Depending on the type, they might use electromagnetic induction, mechanical motion, pressure changes, or ultrasonic waves to measure flow. |

| Design and Construction | Simple design with a tapered tube and float. It doesn’t require external power for operation, making it highly reliable. | Designs vary widely, from electronic devices with sensors to mechanical turbines. Many require external power or batteries. |

| Accuracy | Rotameter provides moderate accuracy (±0.5~2.5%) and is appropriate for general-purpose flow measurement. | Advanced flow meters like Coriolis or ultrasonic meters provide high accuracy (±0.1~1.5%), making them suitable for precision-critical tasks. |

| Measurement Range | Best for low to medium flow rates. They struggle with very high flow rates or applications involving pulsating flows. | Suitable for a broader range of flow rates, including extremely high or low volumes. |

| Fluid Compatibility | Works with clean liquids and gases. Special materials may be needed for corrosive fluids. | Many can handle viscous, corrosive, or multi-phase fluids, depending on the type. |

| Installation Requirements | Requires vertical installation with a consistent flow direction (bottom to top). | Installation flexibility depends on the type. For example, ultrasonic meters can work non-invasively, while turbine meters need precise alignment. |

| Cost– effectiveness | Generally more affordable due to its simple construction. Ideal for budget applications. | Costs vary widely. High-end models like Coriolis meters are expensive but offer unparalleled precision. |

| Rotameter vs Other Flow meters | Rotameter | Other flow meters |

| Advantages | Simple to use and maintain. No external power required. Cost-effective solution for basic flow measurement. | High accuracy and versatility. Broad range of measurement capabilities. Advanced models can provide digital outputs and integrate with control systems. |

| Limitations | Limited accuracy and range. Restricted to vertical installation. Not suitable for opaque or viscous fluids. | Higher initial cost. Some require power and complex setup. Maintenance needs vary based on type. |

More Flow Measurement Solutions

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

- Guide for High Pressure Flow Meters – Industrial Liquid & Gas Measurement

- Guide To Low Temperature Flow Meters: Accuracy In Cold Fluid Measurement

- Solution For Low Flow And Low Volume Applications: Low Flow Meter In Detail

- BTU Meter Optimizes Energy Efficiency of Hot and Cold Water Systems

- Turbine Water Flow Meter: A Versatile And Reliable Choice For Water Flow Measurement

- Pulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

- Guide On Industrial Air Flow Measurement Devices

While rotameters provide a cost-effective and simple solution for moderate accuracy needs, other flow meters cater to a broader range of applications, offering high precision and versatility.

By evaluating your specific requirements, budget, and operational environment, you can make an informed decision and optimize your flow measurement processes.

Sino-Inst produces and supplies various types of rotor flowmeters and other types of flowmeters. If you need to purchase, or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)