- The resistance strain gauge is an integrated product consisting of a sensitive element and an integrated circuit, with high precision, stable and reliable performance;

- Output forward and reverse torque signals;

- Both ends are keyed;

- The speed can reach 300RPM, and the maintenance cycle is 10 million revolutions;

CL1-200 Dynamic Torque Sensor Technical Parameters

| Range | 0-200, 300, 500, 1000, 2000Nm | Output resistance | 350±10Ω |

| Output | 1.5mV/V±10%F.S. | Response frequency | 100μS |

| Accuracy | ±0.1,±0.2%F.S. | Insulation resistance | ≥2000MΩ/100VDC |

| Zero temperature effect | ±0.03%F.S. | Safe overload | 150%F.S |

| Full-scale temperature effect | ±0.03%F.S. | Ultimate overload | 200%F.S. |

| Compensated temperature range | -10~60℃ | Cable size | φ5×3m |

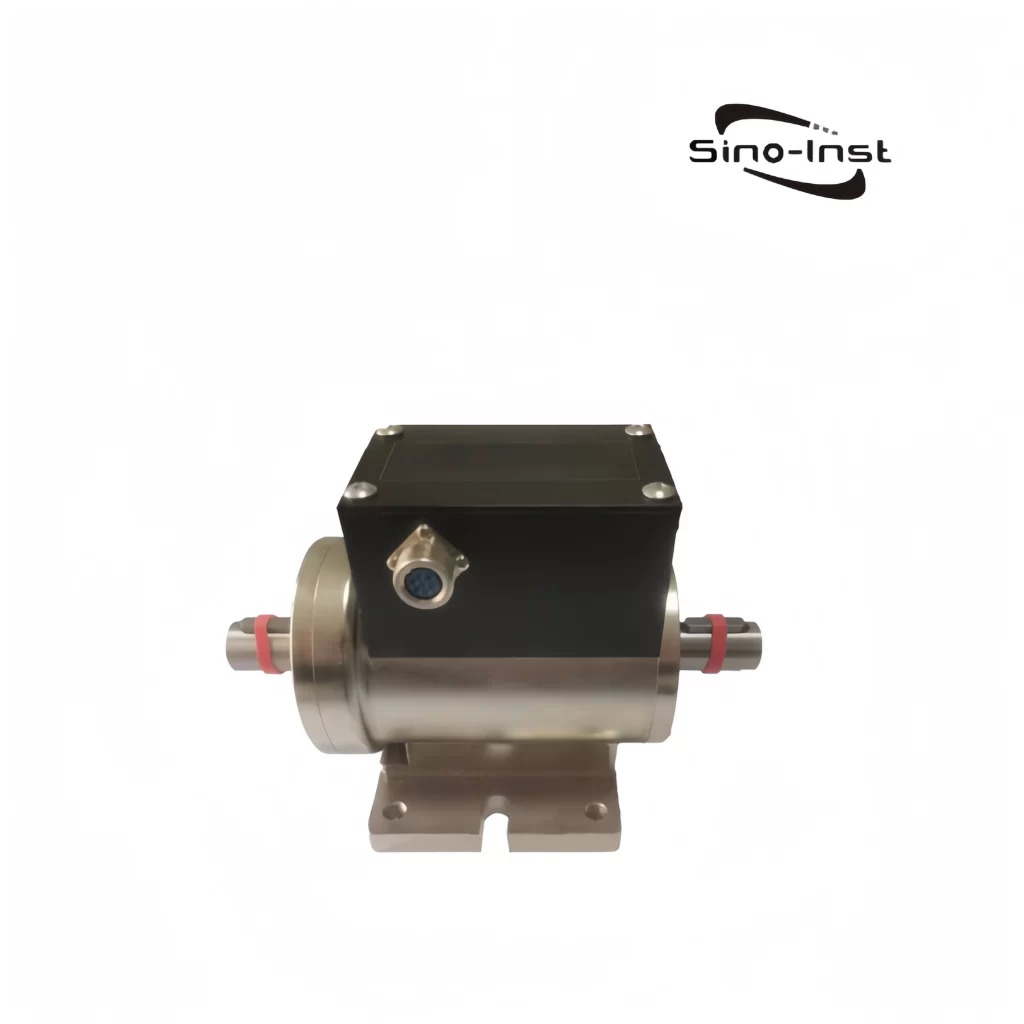

| Operating temperature range | -20-75℃ | Material | Shaft material 17-4PH stainless steel, housing aluminum |

| Supply voltage | 5-10VDC | Electrical connection | Red/E+, Black/E-, Green/S+, White/S- |

| Input resistance | 350±20Ω | Special shaft length | Customizable |

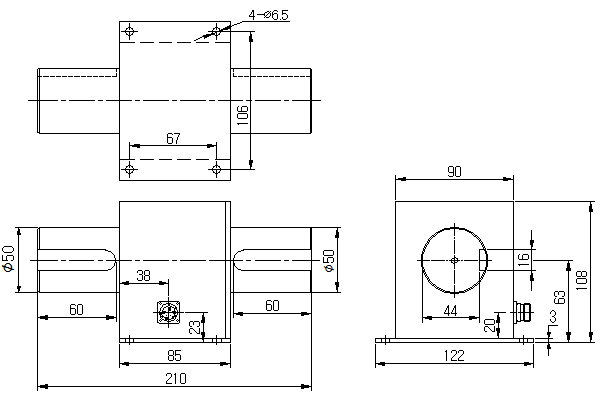

Dimensions

How to determine the range of a dynamic torque sensor?

No matter what sensor is used now, the first thing to do is to determine the range of the sensor, and torque sensors are no exception. How to calculate the range of the torque sensor when you don’t know it? Let’s talk about the range calculation method of the dynamic torque sensor.

The calculation formula of the torque sensor is generally as follows: M=9550×P/N.

Where M is the torque, in N.m; P is the motor power, in KW; N is the speed, in r/min.

This is the calculation formula for the torque sensor range. So when selecting a torque sensor, if we don’t know how much range of torque sensor to choose. We can also calculate it through this formula.

Of course, there are other factors to consider. For example, if the motor you use is a three-phase induction motor, due to the large instantaneous torque of the motor starting, it is recommended that the torque range should be selected as 2-3 times the rated torque. Only by comprehensive consideration can you choose a torque sensor with a suitable range.

More Torque Transducers and Solutions

Torque sensors are widely used in the detection of torque, speed, and power of motors, generators, reducers, and diesel engines. Torque sensors can generally be divided into dynamic torque sensors and static torque sensors. The use of dynamic torque sensors is far greater than that of static torque sensors.

Sino-Inst produces and supplies various types of dynamic torque sensors. If you need to purchase or have related technical questions, please feel free to contact our engineers!

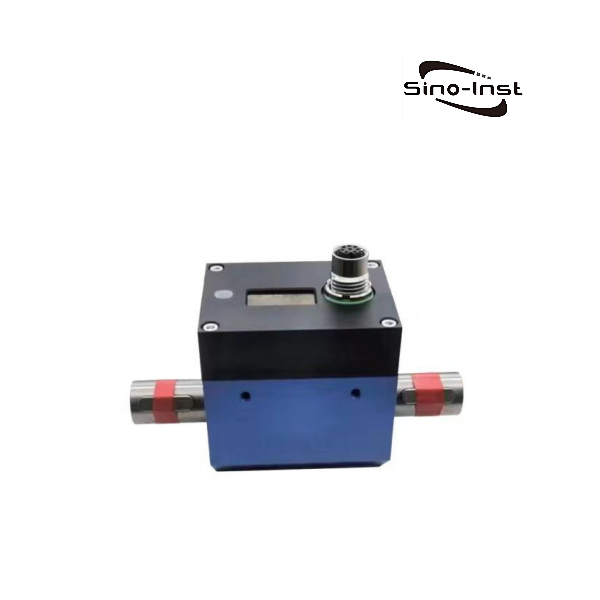

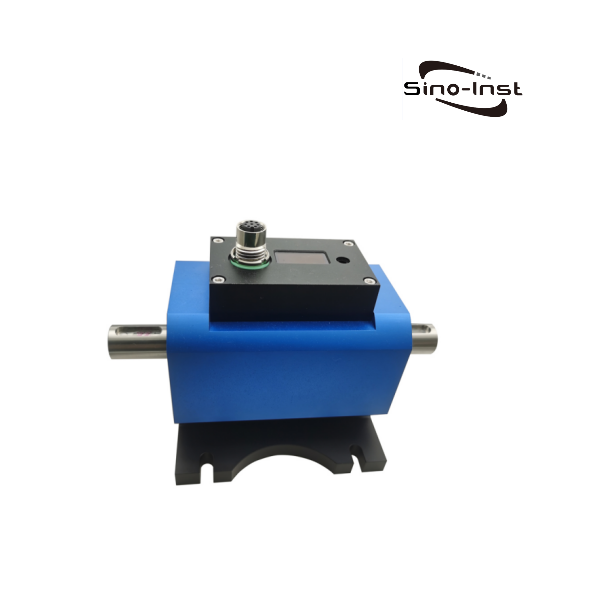

CL1-200 Dynamic Torque Sensor - Positive and Negative Torque

No matter what sensor is used now, the first thing to do is to determine the range of the sensor, and torque sensors are no exception. How to calculate the range of the torque sensor when you don't know it? Let's talk about the range calculation method of the dynamic torque sensor.

Product SKU: CL1-200 Dynamic Torque Sensor

Product Brand: Sino-Inst

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)