What is a Vortex Flow Meter?

Vortex flow meters are a common type of flow meter that uses the von Karman effect to measure fluid flow. Vortices are alternately shed downstream of a bluff body. The frequency of vortex shedding is proportional to the velocity of the fluid flowing through the flowmeter.

Vortex flow meters offer exceptional reliability in measuring gas, liquid, and steam flows. Optional integrated temperature and pressure sensors provide compensated mass flow. Sino-Inst’s vortex flow meters also offer optional energy monitoring, providing reliable energy (BTU) measurement for water, thermal oil, and steam.

Featured Vortex Flow Meters

Benefits

Vortex Flow Meters Types

Classification by sensor structure:

- Pipeline vortex flowmeter. Suitable for measuring flow in small and medium-diameter pipelines.

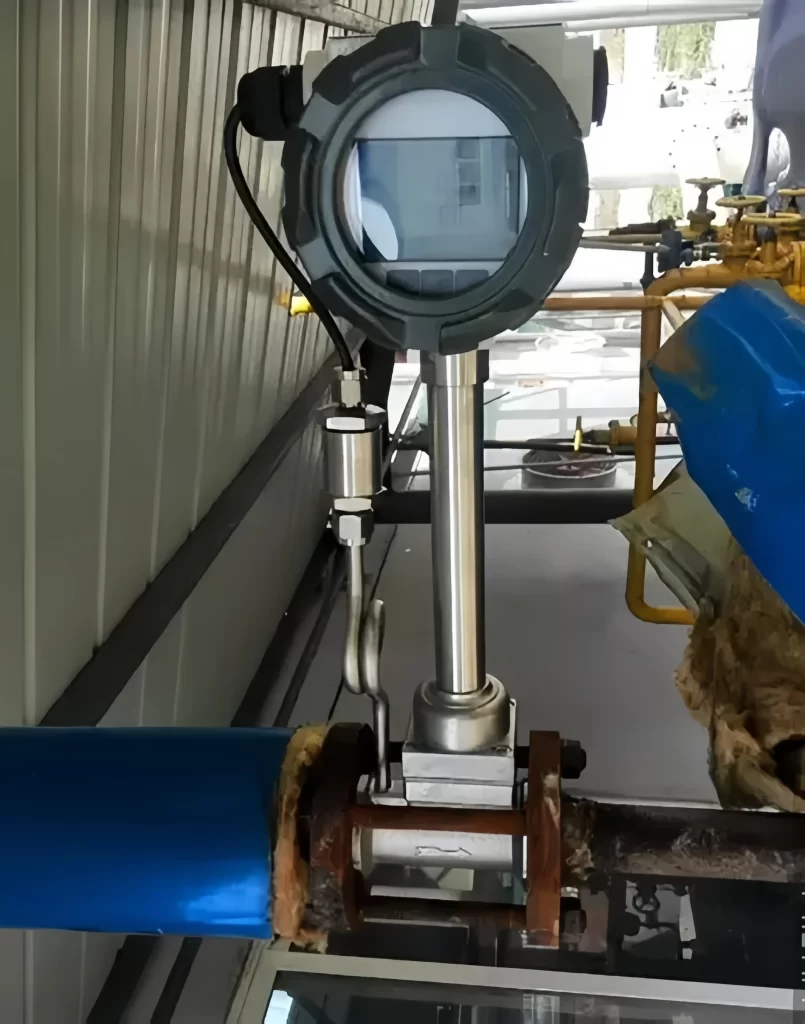

- Insertion vortex flowmeter. Mainly used for measuring flow in large-diameter pipelines.

Classification by connection method:

- Flange-connected vortex flowmeter. Connects to the pipeline via a flange and is suitable for applications requiring frequent disassembly and maintenance.

- Flange-clamp-mounted vortex flowmeter. The meter body does not have a connecting flange and is clamped to the pipeline via a dedicated flange.

- Clamp-mounted vortex flowmeter. The flowmeter is secured to the pipeline via a clamp and features temperature and pressure compensation.

- External thread intelligent vortex flowmeter. This flowmeter has an external thread connection method, which is easy to install and maintain.

- Insertion vortex flowmeter. Mainly used for measuring fluid flow in large-diameter pipelines, it features low pressure loss, a wide measuring range, and high accuracy.

Vortex Flowmeter Flow Measurement Technology

The working principle of the vortex flowmeter is based on the Karman vortex principle, which was discovered and deeply studied by the American-Hungarian scientist von Karman in 1911.

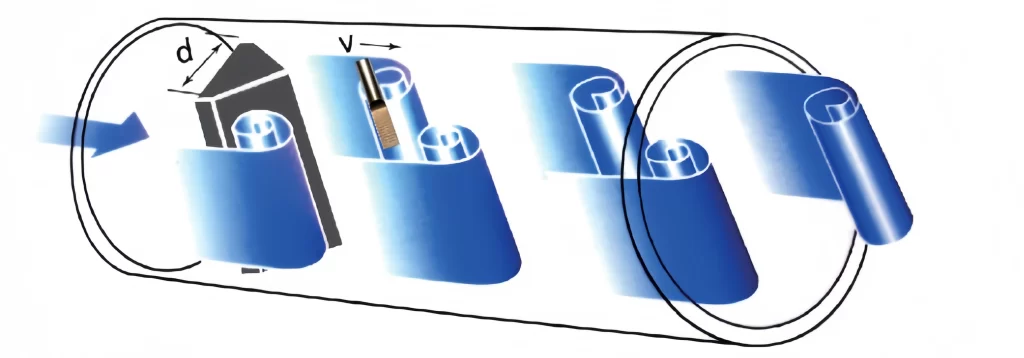

When a fluid (such as gas or liquid) flows through a non-streamlined object, pairs of vortices with opposite rotation directions will appear alternately on both sides of the object’s wake. These vortices are arranged at a certain frequency to form the so-called Karman vortex street.

The frequency of the vortex generation is proportional to the flow rate of the fluid and inversely proportional to the diameter of the vortex generator. The relationship is Sr=fd/V.

Where Sr is the Strouhal constant, f is the vortex frequency, d is the vortex shedding diameter, and V is the flow velocity. The vortex flowmeter measures the vortex shedding frequency to deduce the fluid velocity or flow rate.

Read more about: Vortex flowmeter From Wikipedia

And, Vortex Flow Meter Technology.

Precession Vortex Flow Meter vs. Vortex Shedding Flow Meter

Both vortex flowmeters and precession vortex flowmeters are based on the principle of fluid vibration, but their structures, principles, and applicable scenarios differ.

A vortex flowmeter uses the Karman vortex street generated when fluid passes through a blunt body to detect the vortex frequency and calculate flow rate. The output signal is proportional to the flow velocity.

A precession vortex flowmeter forces the fluid through spiral guide vanes, creating a forced rotation. After acceleration in the contraction section, the precession frequency of the vortex center is correlated with the flow rate, resulting in a stronger signal but greater pressure loss.

| Features | Vortex Flowmeter | Precession Vortex Flowmeter |

| Measurement accuracy | ±1% to ±1.5% (better at high flow rates) | ±1% to ±1.5% (more stable at low flow rates) |

| Range ratio | 10:1 to 30:1 (wider) | 10:1 to 15:1 (slightly narrower) |

| Pressure loss | Small | Larger |

| Vibration resistance | Weaker | Stronger |

| Applicable pipe diameter | DN15 to DN1000 | DN15 to DN200 |

| Pressure resistance | 4 MPa | 4.0 MPa, 6.3 MPa, 10 MPa, 16 MPa, 25 MPa, 42 MPa |

| Fluid compatibility | Clean Gas/Liquid/Steam | Measures gas only. |

| Applicable scenarios | Low pressure loss requirements (e.g., natural gas pipelines, steam metering). | Measures low flow rates (stronger signal at low flow rates). Medium containing light particles (such as coalbed methane and wet gas). Environment with high vibration interference (such as near pumps). |

Wide Measurement Range

Vortex flowmeters are suitable for measuring the flow of most liquids and gases. They are also the preferred flowmeter for steam flow measurement. They are widely used for flow measurement in the petrochemical, power generation, steel, chemical, and water conservancy industries.

1. Liquid Vortex Flowmeter

Features: Suitable for measuring the flow of liquids such as water, oil, and chemical solutions.

Applications: Water treatment, chemical, and oil and gas industries.

2. Gas Vortex Flowmeter

Features: Suitable for measuring the flow of gases such as air, natural gas, and steam.

Applications: Power generation, oil and gas, and chemical industries.

3. Steam Vortex Flowmeter

Features: Suitable for measuring the flow of saturated and superheated steam.

Applications: Power generation, chemical, and food and beverage industries.

More Flow Measurement Solutions

Vortex flowmeters are primarily used to measure the flow of fluids in industrial pipelines, such as gases, liquids, and steam. Our Sino-Inst vortex flowmeters offer both analog standard and digital pulse outputs, making them easy to use with computers and other digital systems.

If you need flow measurement or are looking to purchase a vortex flowmeter, please feel free to contact our sales engineers!

-1.jpg)