Accurate and reliable liquid level measurement is critical for many applications. Whether in industrial or civil fields, liquid level measurement can easily grasp the height of the liquid. That is the distance between the liquid and the top of the container. Including monitoring and controlling the level of liquids in storage tanks.

Level measurement primarily uses probes or other sensors to determine the height of liquid in a container. When you need liquid level measurement, we at Sino-Inst offer a wide range of options. Including float level meter, capacitance level meter, radar level meter, etc.

What is Liquid Level Measurement?

Level measurement is the process of determining the position of liquid within a container, tank, or other container. In many applications, level measurement is critical to maintaining process efficiency and ensuring safety. And they are widely trusted by industries including manufacturing, food processing, oil and gas.

How Do You Measure Liquid Level?

There are a variety of liquid level measurement methods, including hydrostatic, ultrasonic, radar and float systems. Hydrostatic pressure is suitable for storage tanks and rivers. While capacitive sensors measure electrical properties, float switches provide simple presence detection.

Types of Liquid Level Measurement

Level measurement types include continuous measurement and point level measurement. They typically use technologies such as hydrostatic, ultrasonic, radar, capacitive, and float. Hydrostatic pressure and radar are often used for continuous measurements. While float and capacitive sensors can be used for both.

Continuous level measurement provides real-time information on the liquid level in the tank. It is commonly used in applications such as real-time process control as well as precise inventory management. Continuous level measurement usually uses hydrostatic pressure, ultrasonic, radar.

Point level measurement detects whether the liquid in a tank has reached a specific level. It provides a simple “on/off” signal at a single point indicating high, low or medium level. Typically used for process control and triggering alarms. For example to prevent spills or pumps from running dry. Common technologies for point level measurement include float switches, capacitive switches, etc.

Common Liquid Level Measurement Technologies

Hydrostatic pressure works based on a pressure sensor at the bottom of the tank measuring the hydrostatic pressure of the liquid above it. and convert it to liquid level. The higher the liquid height, the greater the pressure. Hydrostatic pressure sensors are suitable for open tanks, rivers and wells. But when you use hydrostatic pressure to measure liquid level, you need to know the specific gravity of the liquid to convert pressure to height.

Ultrasonic sensors use sound waves to measure the level of liquid in a container. No contact with liquids required. Suitable for measuring hot, corrosive or clean liquids.

An ultrasonic transmitter sends sound waves and measures the time it takes for the sound waves to reflect off the surface of the liquid and return. This “time of flight” is used to calculate distance. Distance is calculated using this formula: Distance = (Time x Speed of Sound)/2. If we know the distance from the sensor to the bottom of the tank, then subtract the calculated distance to get the liquid level.

Radar sensors are similar to ultrasonic sensors. They transmit radar pulses and measure the time delay of the reflected signal. Moreover, they can measure through non-conductive materials, pastes, or powders. This method is suitable for turbulent or corrosive liquids.

A float rises and falls with the liquid level. At specific points, it triggers a switch or provides a continuous position signal. This movement can be connected to a mechanical or electrical system to indicate the liquid level. Float sensors provide simple, reliable level measurement for basic on/off applications.

Capacitive sensors work by measuring the conductivity or capacitance of a liquid. They can detect the presence and level of conductive liquids. For non-metallic tanks, capacitive sensors can be mounted externally on plastic, glass, or ceramic tanks. For industrial tanks or corrosive liquids, internal capacitive sensors are available.

Magnetostrictive level transmitters use the principle of magnetostriction to measure liquid level. It is a reliable and proven technology with high measurement accuracy. They are suitable for corrosive, high-temperature, or high-pressure environments.

Choosing the Right Level Measurement Technology: Radar vs. Ultrasonic

Radar sensors are the best choice for harsh environments like those with dust, steam, or foam. Because they are less affected by temperature, density, and air conditions. They can also measure through foam or steam. While radar sensors offer high accuracy, they are generally more expensive and complex to install. They can also sometimes experience material buildup on the antenna.

For simpler, cleaner applications, you can use ultrasonic sensors to measure liquid levels. Ultrasonic sensors offer high stability. And they are suitable for clean liquids under non-demanding conditions. They are also more cost-effective and easier to use. However, ultrasonic sensors are susceptible to steam, foam, temperature fluctuations, or dust.a

If accuracy is not a priority, ultrasonic sensors are a more cost-effective solution. For the most reliable performance in a wide range of applications, radar is often a better choice. However, cost and complexity must be considered.

Level Meters for Liquid Level Measurement

Liquid level measurement can be categorized as either non-contact or contact. Therefore, when selecting a level measurement solution, it is important to understand the difference between contact and non-contact sensors.

| Type | Description | Pros | Cons | Rep |

| Non-contact liquid level measurement | Non-contact level measurement measures liquid level without physical contact. | Low maintenance.No moving parts in contact with the media.Suitable for harsh environments. | Higher price.May be significantly affected by temperature, humidity, and pressure. | Radar level meter, Ultrasonic level meter, Photoelectric level meter |

| Contact liquid level measurement | Contact sensors measure liquid level by physically contacting the liquid. | Easier to install and operate.Lower initial cost. | Typically less accurate and more susceptible to fluid fluctuations.Requires more maintenance. | Float level transmitter, Capacitive level transmitter, Magnetostrictive level transmitter |

Non-Contact Liquid Level Sensors

1. Radar Level Meter

Radar level meters calculate liquid levels by using the time difference between transmitting a microwave signal and receiving the reflected signal. The most commonly used type is the 80G radar level meter. Radar level meters offer high accuracy and are unaffected by temperature and pressure. They are suitable for high-temperature and high-pressure environments. They have a measurement range of up to 150 meters. However, they are relatively expensive.

2. Ultrasonic Level Meter

An ultrasonic level meter calculates liquid level by emitting an ultrasonic signal and measuring its reflection time. It uses non-contact measurement and is easy to install. However, ultrasonic level meters are significantly affected by temperature, humidity, and pressure. Their accuracy is slightly lower than that of radar level meters. For sealed tanks, you can choose an external ultrasonic level meter.

3. Photoelectric Level Meter

Photoelectric level meters utilize the principles of light refraction and reflection. They detect liquid level changes using a photoelectric sensor. And they employ non-contact measurement and offer high accuracy and fast response. So they are suitable for measuring the level of transparent or translucent liquids. Such as mineral water and alcohol. However, they are significantly affected by lighting conditions.

Contact Liquid Level Sensors

1. Float Level Sensors

Float level sensors measure liquid level by using the principle that a float rises and falls with the liquid level. Through mechanical or magnetic transmission, the level change is converted into an indicator signal.

They feature a simple structure and are easy to install and maintain. They can be customized as either a float level transmitter or a float level switch. However, float level sensors generally have low accuracy and are significantly affected by liquid fluctuations.

2. Capacitive Level Meter

Capacitive level meters use a capacitive sensor to measure the change in capacitance of a liquid to determine the liquid level. They utilize a non-contact measurement method. And they offer high accuracy and fast response speed. Capacitive level meters are widely used in industries such as chemical, food, and beverages.

3. Magnetostrictive Level Transmitter

Magnetostrictive level transmitters use the magnetostrictive effect to measure liquid level. In addition to their use in the petroleum, chemical, and food and beverage industries, they are also used for high-precision level measurement. They are also unaffected by the properties of the liquid. However, they are relatively expensive.

4. Hydrostatic Level Transmitter

A hydrostatic level transmitter measures tank level by detecting the pressure at the bottom of a column of liquid. This pressure, known as hydrostatic pressure, increases with the height of the liquid. Therefore, the level meter is able to convert the pressure reading into a usable signal, thus accurately measuring the liquid level. It is ideal for level measurement in deep tanks, wells, and reservoirs.

Pressure level transmitters also use the hydrostatic pressure principle to measure liquid levels. They offer high accuracy and are easy to install. They are suitable for use in sealed containers. However, they are susceptible to changes in liquid density and require regular calibration. In addition to chemical plants and water treatment plants, they are also used for level measurement of viscous liquids.

How Do You Measure the Liquid Level in a Container?

You can measure liquid level using a variety of methods. These include directly measuring the volume of smaller containers using a graduated cylinder. Alternatively, you can use a pressure sensor (hydrostatic pressure) to measure the volume of larger containers. Ultrasonic, radar, capacitance, and floats can also be used to measure liquid level in containers.

Graduated cylinders are the most common tool for measuring liquid volume in laboratory settings. When using a graduated cylinder for small-scale measurements, your eye should be at eye level with the liquid surface to avoid parallax errors. For most liquids, such as water, you read the volume at the bottom of the meniscus (curve). For liquids like mercury, read the volume from the top of the curve.

For large-scale or industrial applications, the sensor is immersed in the liquid or placed on the bottom of the tank to measure the pressure exerted by the liquid’s weight. For sealed tanks, the pressure above the liquid (head pressure) must be considered for accurate readings.

How Do You Measure the Liquid Level in a Storage Tank?

For sealed tanks with corrosive or volatile media, openings are not permitted. In such cases, externally mounted ultrasonic level sensors are the only option. These sensors utilize the principle of internal acoustic echo ranging.They utilize advanced digital signal processing technology. This overcomes the effects of the tank wall on ultrasonic signal transmission. They enable truly non-contact measurement of liquid levels within sealed containers.

Typically, ultrasonic sensors are mounted directly below the outer wall of the container being measured. This eliminates the need for drilling holes in the container. They can accurately measure various liquid levels within high-pressure, sealed containers.

If the tank is a conventional sealed storage tank with viscous, high-pressure, or high-temperature media, we can choose a differential pressure transmitter. A differential pressure transmitter measures the pressure difference between two points in the system and converts it into an electrical signal for level monitoring. It can also measure the level in open or pressurized vessels.

Radar level meters use a non-contact method. For conventional media, if the pressure and temperature permit, a radar level meter can be top-mounted.

Capacitive level transmitters use capacitance between two conductive plates to measure liquid level. They are suitable for use in extreme temperature and pressure environments. For cryogenic liquid storage tanks, we use low-temperature capacitance level meters. For ultra-high-pressure liquid storage tanks, we use high-pressure capacitance level meters.

For larger tanks, we can use radar transmitters. They have a range of up to 150 meters. They offer high accuracy and are capable of operating in harsh environments. They are also suitable for high-temperature and high-pressure tanks. However, they are more expensive than ultrasonic or capacitive level transmitters.

For conventional media such as diesel and water, we can use ultrasonic level meters. These use a non-contact measurement method and are suitable for corrosive or hazardous liquids. They are also relatively affordable.

How Do You Measure the Liquid Nitrogen Level?

Liquid nitrogen is a commonly used industrial gas. It possesses extremely low temperatures and powerful refrigeration capacity. Liquid nitrogen has important applications across a wide range of industries. Therefore, monitoring and controlling liquid nitrogen levels is crucial. Our liquid nitrogen tank level meters can be used to monitor the liquid nitrogen level in ultra-low temperature containers.

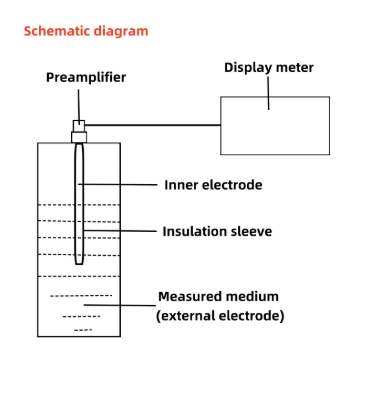

As shown in the figure above, a metal rod is inserted into a liquid nitrogen tank. The rod acts as one electrode of a capacitor, and the tank wall acts as the other. The medium between the two electrodes is the liquid and the gas above the liquid surface. Due to the different dielectric constants of the liquid and gas, as the liquid level rises, the total dielectric constant between the two electrodes increases, resulting in an increase in capacitance.

Real-time performance is a key feature of capacitive level meters. They enable continuous, real-time measurement of the tank’s liquid level. To adapt to diverse and complex industrial environments, capacitive level meters are designed and manufactured using high-quality stainless steel.

More Level Measurement Case

More Level Measurement Solutions

Liquid level measurement is crucial for monitoring fluid storage and controlling production processes. It provides real-time monitoring of liquid levels in tanks and containers. And it ensures stable and safe system operation. Through the above detailed introduction, you can quickly understand different types of liquid level gauges.

Today, liquid level sensors are made from a growing variety of materials and alloys. Sino-Inst manufactures and offers a full range of liquid level transmitters. If you need to measure liquid or material levels, please feel free to contact our sales engineers!

-1.jpg)