Best Technology Guide to Thermal Mass Flow Meters.

A thermal mass flowmeter (TMF) is a gas flowmeter designed based on the principles of thermal diffusion or heat conduction. It directly measures the mass flow of gas without the need for additional temperature and pressure compensation.

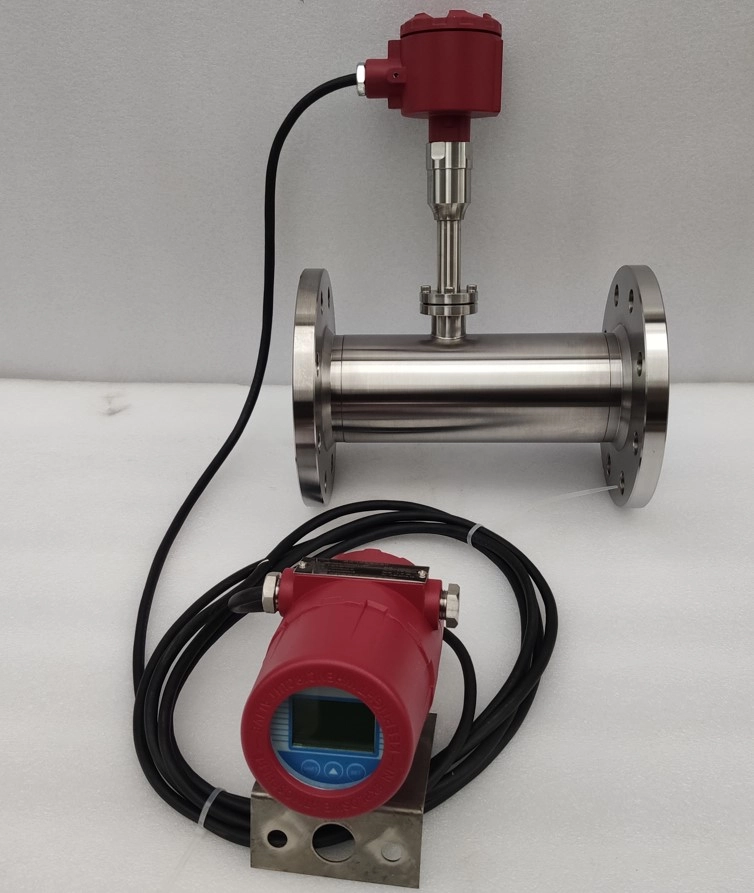

Sino-Inst’s Thermal mass flowmeters are the preferred flowmeter for gases. Such as nitrogen, compressed air, natural gas, and hydrogen in industrial processes.

Sino-Inst is a professional manufacturer of thermal gas mass flowmeters. We provide thermal mass flowmeters covering DN10~DN4000. Based on many years of experience in gas measurement and control services, we are here to share with you the advantages, principles, applications, etc. of thermal mass flowmeters. We hope it will help you choose the right gas flowmeter.

Featured Thermal Mass Flow Meters

Thermal Mass Flow Meter Working Principle

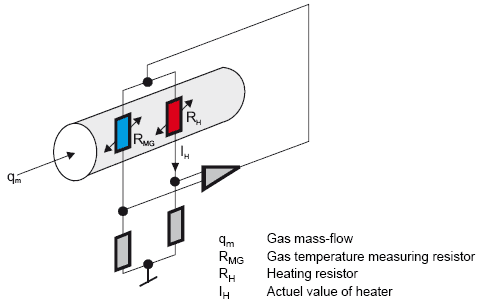

A thermal gas mass flowmeter is a meter that measures the mass flow of gas using the principle of heat conduction. The sensor of the thermal mass flowmeter consists of two reference thermal resistors (platinum RTD). One is the mass speed sensor T1, and the other is the temperature sensor T2 that measures the temperature change of the gas.

When these two RTDs are placed in the measured gas, the sensor T1 is heated to a constant temperature difference above the gas temperature, and the other sensor T2 is used to sense the temperature of the measured gas.

As the mass flow rate of the gas increases, the airflow takes away more heat, and the temperature of the sensor T1 decreases. To maintain a constant temperature difference between T1 and T2, the heating power of T1 must increase.

According to King’s law of thermal effects, there is a certain mathematical relationship between heating power P, temperature difference △ T (T1-T2) and mass flow Q.

P / △ T = K1 + K2 f (Q) K3

K1, K2, and K3 are constants related to the physical properties of the gas.

Specifications of Thermal Mass Flow Meters

| Medium | All gases (except acetylene) | |||||

| Pipe diameter | DN10-80 (Flange type) | DN100-6000 (Insert type) | Split type (support customized) | |||

| Flow rate | 0.5-100m/s | |||||

| Accuracy | Pipeline type 1.5%. Insertion type 2.5% | |||||

| Operating temp. | Sensor | Default type: -10~+200℃ | ||||

| High temp. type: -10~350℃ | ||||||

| Transmitter | -20~+45℃ | |||||

| Operating pressure | Medium pressure≤10MPa | Medium pressure≤2.5MPa | ||||

| Power supply | Compact type | DC24V or AC220V≤18W | ||||

| Remote type | AC220V≤19W | |||||

| Response time | 1s | |||||

| Output | 4-20mA | Optical isolation, max. load 500Ω | ||||

| RS485 | Optical isolation | |||||

| HART | ||||||

| Pipe material | Carbon steel, stainless steel, plastic, etc. | |||||

| Display | Compact type: 4 lines LCD display | |||||

| Display content | Mass flow, standard volume flow, accumulated flow, time, accumulated time, medium temp., standard flow, etc. | |||||

| Ingress protection | IP67 (sensor part) | |||||

| Sensor material | Stainless steel | Stainless / carbon steel | ||||

Benefits of Thermal Mass Flow Meters

Thermal Mass Flow Meter Advantages and Disadvantages

| Advantages | Disadvantages |

| Directly measure mass flow without temperature and pressure compensation. | Thermal mass flowmeter responds slowly. |

| Fast response speed, can reflect flow changes in real time. | High requirements for flow field, need to maintain a stable flow field to obtain accurate measurement results. |

| Wide measurement range, suitable for a variety of gases and flow ranges. | Requirements for pipeline materials, need to have good thermal conductivity. |

| Good stability and long service life. | Pulsating flow will be limited in use. |

| No moving parts, no obstructions, small pressure loss. | Thermal mass flowmeter for liquids is also limited in use for viscous liquids. |

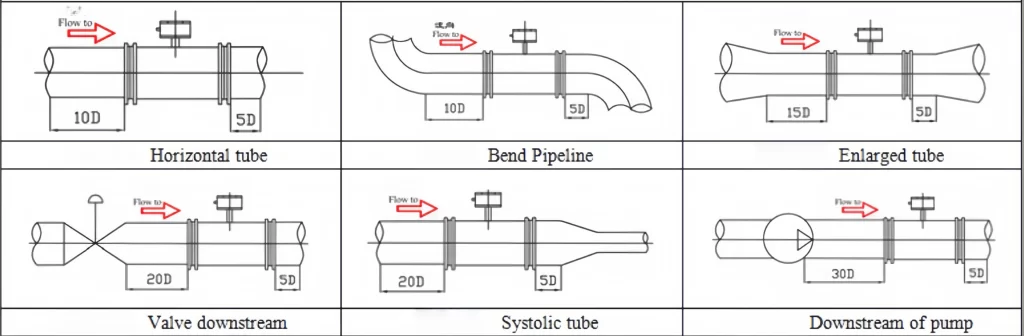

Thermal Mass Flow Meter Installation: Upstream and Downstream Straight Pipe Requirements

When installing a thermal mass flowmeter, keep it away from elbows, obstacles, reducers, and valves to ensure a stable flow field. The straight pipe lengths before and after a thermal mass flow meter must meet the following requirements:

- In conventional horizontal piping or when there is an upstream bend, the upstream straight pipe length of the thermal mass flow meter must be greater than 10D, and the downstream straight pipe length must be greater than 5D.

- When there is an expansion pipe upstream or downstream, the upstream straight pipe length of the thermal mass flow meter must be greater than 15D, and the downstream straight pipe length must be greater than 5D.

- When there is an upstream valve, the upstream straight pipe length of the thermal mass flow meter must be greater than 20D, and the downstream straight pipe length must be greater than 5D.

- When there is a contraction pipe downstream, the upstream straight pipe length of the thermal mass flow meter must be greater than 20D, and the downstream straight pipe length must be greater than 5D.

- When there is a pump upstream, the upstream straight pipe length of the thermal mass flow meter must be greater than 30D, and the downstream straight pipe length must be greater than 5D.

Thermal Mass Flow Meter Applications

- Measurement of oxygen, nitrogen, hydrogen, chlorine and multi-component gases.

- Measurement of blast furnace gas and coke oven gas.

- Flue gas measurement.

- Aeration and chlorine measurement in biogas and water treatment.

- Compressed air measurement.

- Flow measurement of natural gas, liquefied gas, flare gas, etc.

- Primary and secondary air flow measurement of power plant blast furnace

- Flow measurement of underground ventilation or exhaust system.

Based on our many years of experience in gas measurement services. We have compiled and summarized the media suitable for thermal mass flow meters for your reference:

Gases Commonly Measured with Thermal Mass Flow Meters:

- Oxygen (O2)

- Nitrogen (N2)

- Carbon dioxide (CO2)

- Hydrogen (H2)

- Chlorine gas,

- Argon (Ar)

- Helium (He)

- Natural gas,

- Liquefied gas,

- Compressed air

- Multi-component gas measurement of biogas,

- Methane (CH4)

- Aeration and chlorine measurement in water treatment,

- Gases,

- Carbon dioxide gas flow rate during beer production,

- Gas flow during the semiconductor chip manufacturing process,

- Gas flow measurement in solvent recovery systems

- Blast furnace gas,

- Coke oven gas,

- Flue gas,

- During the gas process, air,

- Calcining furnace flue gas,

- Combustion gas measurement in coal-fired boilers.

- Smoke flow (speed) measurement of smoked meat (CEMS)

- Primary air, secondary air,

- Mine ventilation or exhaust system flow,

- Gas flow (velocity) measurement in heating, ventilation, and air conditioning systems

- And many more… (Comments are welcome to add)

If you are not sure whether you can choose a thermal mass flowmeter for your measurement conditions, please feel free to contact our Sino-Inst technical engineers!

Our Advanced Service Solutions for Thermal Mass Flowmeters

Thermal Mass Flow Meter Price

Sino-Inst is a manufacturer of thermal mass flow meters. We offer a variety of mass flow meter products and a full range of consulting services for flow measurement solutions, instrumentation, sub-assembly, design and fabrication, engineering, calibration and certification.

Thermal mass flow meter price is decided by your measurement details. Please offer your information like:

- Measurement medium:

- Pipe caliber:

- Measure temperature:

- Measure pressure:

- Installation method:

- output signal:

- Material requirements:

All these parameters will affect the price. But we will surely offer you the best price.

Technical Support

More Flow Measurement Solutions

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flowmeter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

Inline Compressed Air Flow

A Compressed Air Flow Meter is a digital flow meter that works for the air compressor. Thermal mass, vortex, and DP flowmeters are common gas flow sensors.

Air consumption is an important info for industrial inline gas flow pipes. Compressed air is the most expensive form of energy in manufacturing plants. And compressed air accounts for up to 20% of the overall energy costs.

So, It is important to measure compressed air flows precisely in all conditions. This can improve the energy efficiency of compressed air systems while reducing costs.

Natural Gas Flow

Natural gas flowmeter is an online flowmeter used in natural gas pipelines. For example: thermal mass flowmeter, ultrasonic natural gas flowmeter, natural gas turbine flowmeter, intelligent gas vortex flowmeter and differential pressure flowmeter. These are the most common online natural gas flowmeters with digital display.

Choose a suitable natural gas flowmeter according to the measurement conditions of the natural gas pipeline. For example: pressure, temperature, straight pipe length, pipe diameter, insertion or remote installation, etc. If you have any questions about natural gas flowmeter, please contact us.

Sino-Inst is a professional manufacturer of thermal gas mass flowmeters. We serve many industrial processes and laboratories that need to measure gas quickly and accurately. Without any temperature and pressure compensation, thermal mass flowmeters can directly detect the mass flow or volume flow of the measured gas.

Sino-Inst produces and sells more than 10 models of thermal gas mass flowmeters. They are exported to the United States, the United Kingdom, Singapore, Malaysia and other countries. If you need to perform gas flow detection or need a thermal gas mass flowmeter, please feel free to contact us.

Home » Technologies » Thermal Mass Flow Meter Technology

-1.jpg)