A gas mass flow meter utilizes the principle of thermal diffusion to measure gas flow. It can display both volumetric and mass flow rates, enabling precise measurement and control of gas mass flow.

Sino-Inst’s gas mass flow meter, which requires no temperature or pressure compensation, has become the preferred choice for dry gas flow measurement, including oxygen, nitrogen, hydrogen, chlorine, and multi-component gases. It can also measure blast furnace gas, coke oven gas, natural gas, liquefied petroleum gas, flare gas, and other gases.

| Diameter | DN10~DN4000mm |

| Accuracy | ±1.5% |

| Temp. range | -10~350℃ |

| Pressure | Medium pressure≤10MPa |

| Flow rate | 0.5-100m/s |

| Protection | IP67 (sensor part) |

Features

Specifications

| Medium | All gases (except acetylene) | |||||

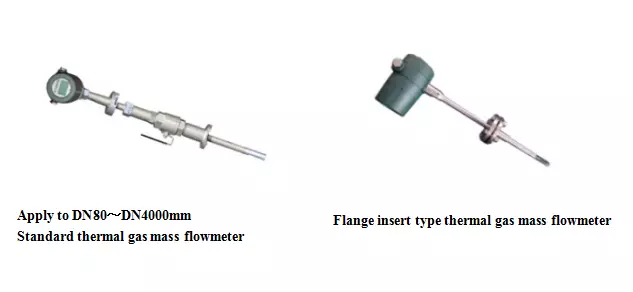

| Pipe diameter | DN10-80 (Flange type) | DN100-6000 (Insert type) | ||||

| Flow rate | 0.5-100Nm/s | |||||

| Accuracy | ±1% | |||||

| Operating temp. | Sensor | Default type: -10~+200℃High temp. type: -10~350℃ | ||||

| Transmitter | -20~+45℃ | |||||

| Operating pressure | Medium pressure≤10MPa | Medium pressure≤2.5MPa | ||||

| Power supply | Compact type | DC24V or AC220V≤18W | ||||

| Remote type | AC220V≤19W | |||||

| Response time | 1s | |||||

| Output | 4-20mA | Optical isolation, max. load 500Ω | ||||

| RS485 | Optical isolation | |||||

| HART | ||||||

| Pipe material | Carbon steel, stainless steel, plastic, etc. | |||||

| Display | Compact type: 4 lines LCD display | |||||

| Display content | Mass flow, standard volume flow, accumulated flow, time, accumulated time, medium temp., standard flow, etc. | |||||

| Ingress protection | IP67 (sensor part) | |||||

| Sensor material | Stainless steel | Compact type: 4-line LCD display | ||||

Order Guide

In addition to regular products, we support customization

| SI-3503 | Thermal mass flow meter |

| Sensor type | C Retrench pattern insert type |

| D Online pluggable type | |

| E Flange pipe type | |

| F Thread pipe type | |

| G Clamp on type | |

| Pipe diameter | C Round pipe: DN15~DN6000 |

| S Square pipe: 25*25mm~2000*2000mm | |

| Housing material | A SUS304 |

| B SUS316 | |

| C Other material | |

| Pressure | S 1.6MPa |

| M 2.5MPa | |

| T 4.0MPa | |

| Temp. | I 10~200℃ |

| II 10~400℃ | |

| Output | 1 4-20mA |

| 2 RS485 | |

| 3 PULSE | |

| 4 Relay contact | |

| 5 HART | |

| Power | DC 24VDC |

| AC 220VAC | |

| Display | J Integrated display |

| S Split display |

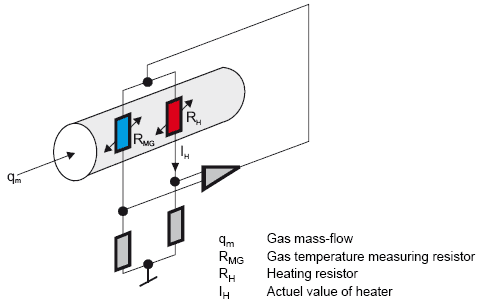

How Does a Gas Mass Flow Meter Work?

A thermal gas mass flowmeter is a meter that measures the mass flow of gas using the principle of heat conduction. The sensor of the thermal mass flowmeter consists of two reference thermal resistors (platinum RTD). One is the mass speed sensor T1, and the other is the temperature sensor T2 that measures the temperature change of the gas.

When these two RTDs are placed in the measured gas, the sensor T1 is heated to a constant temperature difference above the gas temperature, and the other sensor T2 is used to sense the temperature of the measured gas.

As the mass flow rate of the gas increases, the airflow takes away more heat, and the temperature of the sensor T1 decreases. To maintain a constant temperature difference between T1 and T2, the heating power of T1 must increase.

According to King’s law of thermal effects, there is a certain mathematical relationship between heating power P, temperature difference △ T (T1-T2) and mass flow Q.

P / △ T = K1 + K2 f (Q) K3

K1, K2, and K3 are constants related to the physical properties of the gas.

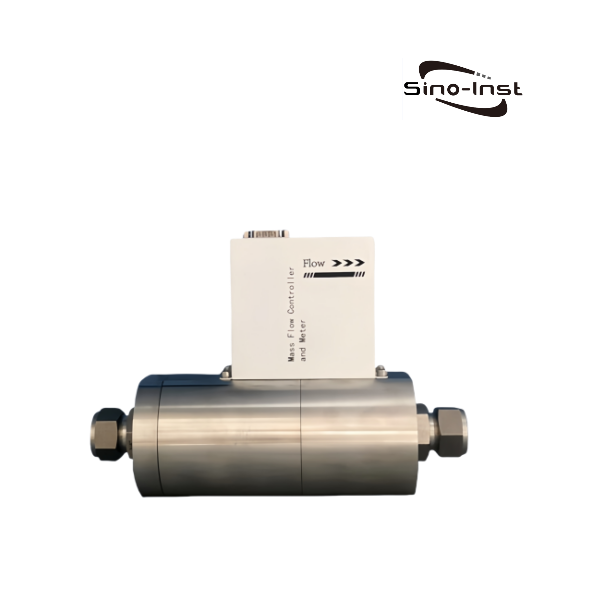

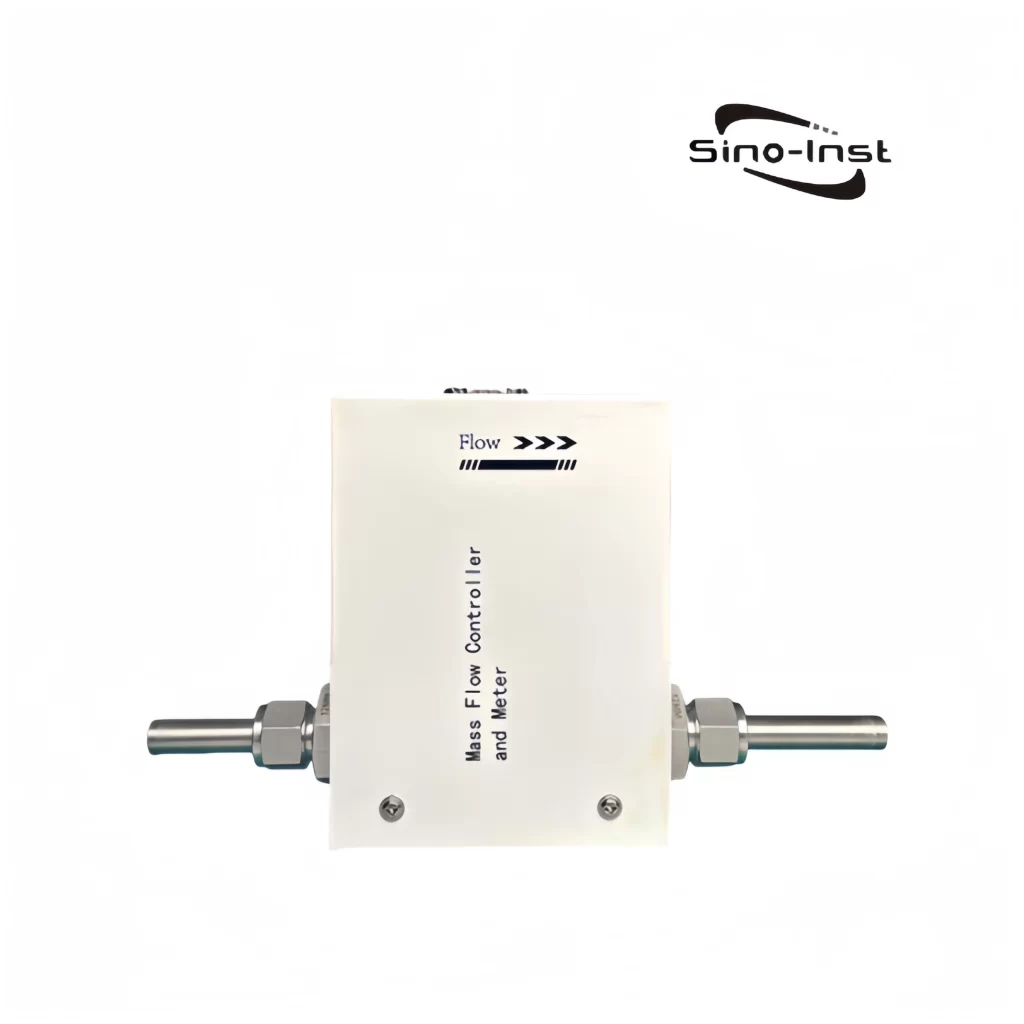

Gas Flow Meters & Gas Flow Controllers

Gas flow meters are used to measure gas flow. Their primary function is to measure gas flow for flow monitoring and control. A flow controller, on the other hand, is an instrument used to precisely control gas flow. Its primary function is to automatically adjust gas flow according to a set flow rate to ensure compliance with requirements in applications such as industrial production and experimental research.

Gas flow meters and flow controllers also differ in their measurement principles. Gas flow meters can measure volume, mass, or differential pressure, while flow controllers typically measure pressure, mass, or valve opening.

Gas flow meters and flow controllers both play important roles in gas flow measurement and control. The differences and connections between them require careful consideration when selecting and coordinating them.

Sino-Inst offers a wide range of products, including mass flow meters and gas flow controllers.

More Gas Flow Measurement Solutions

Selecting the right gas mass flow meter and controller is crucial for achieving accuracy, efficiency, and optimal performance in a variety of fields, including aerospace, biotechnology, energy, semiconductor manufacturing, and laboratory environments.

Gas mass flow meters are primarily used for gas flow measurement, such as monitoring reaction gases in the chemical industry, measuring exhaust emissions for environmental monitoring, and controlling flow in oil and gas pipelines. Our team of dedicated application engineers at Sino-Inst is ready to help you identify the ideal solution for your specific requirements.

-1.jpg)