The Clamp-on Ultrasonic Flow Meter consists of a main unit and a clamp-on sensor. Simply attach the clamp-on sensor to the pipe surface to non-invasively measure the flow rate of various liquids. Compared to traditional flow meters, it requires no pipe or flow interruption, making installation quick and easy, and achieving a truly non-destructive installation.

The Sino-Inst Transit Time Clamp-on Ultrasonic Flow Meter features a fixed wall-mount main unit and built-in SD card storage. It can measure the volumetric flow rate of liquids in pipes ranging from 1/2″ to 240″.

| Diameter | DN15~6000 |

| Accuracy | ±1% |

| Temp. range | -30~160℃ |

| Protection | Host:IP67;flow sensor:IP68 |

| Flow rate | 0~±7m/s,Forward and backward measurement |

| Liquid type | water,sea water ,alcohol,Acid and alkali,waste water,beer,all kinds of oil Single liquid can transmit sound wave. |

Benefits

Specifications

| Items | Performance & Parameter | ||

| Host | Principle | Transit- time ultrasonic flowmeter | |

| Accuracy | ±1% | ||

| Display | 2X20 character LCD with backlight, supports the languages of Chinese, English ,and Italy | ||

| Signal Output | 1 way 4~20mA output, electric resistance 0~ 1K, accuracy 0. 1%(optional);1 way OCT pulse output(Pulse width 6~1000ms, default is 200ms); 1 way Relay output | ||

| Signal Input | 3 way 4~20mA input, accuracy 0. 1%, acquisition signal such as temperature, press and liquid level; Connect the temperature transducer Pt100, can finish the heat/energy measurement | ||

| Data Interface | Insulate RS485 serial interface, upgrade the flowmeter software by computer, support the MODBUS | ||

| Special Cable | Twisted-pair cable, generally, the length under 50 meters; Select the RS485, transmission distance can over 1000m | ||

| Pipe Installation Condition | Pipe Material | Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed | |

| Pipe Diameter | DN32~6000mm | ||

| Straight Pipe | Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump | ||

| Measuring Medium | Medium | water, sea water, alcohol, Acid and alkali, waste water, beer, all kinds of oil Single liquid can transmit sound wave. | |

| Temperature | -30~160℃ | ||

| Turbidity | No more than 10000ppm and less bubble | ||

| Flowrate | 0~±10m/s, Forward and reverse bidirectional measurement | ||

| Work environment | Protection grade | Host:IP67;flow sensor:IP68 | |

| temperature | Host:-20~60℃;flow sensor:-30~ 160℃ | ||

| Humidity | Host: 85%RH; Flow sensor:can measure under water, water depth^2m (tansducer sealed glue) | ||

| Power Supply | DC8~36V or AC85~264V | ||

| Power Consumption | 1.5W | ||

| Dimension | 132*150*85mm(host) | ||

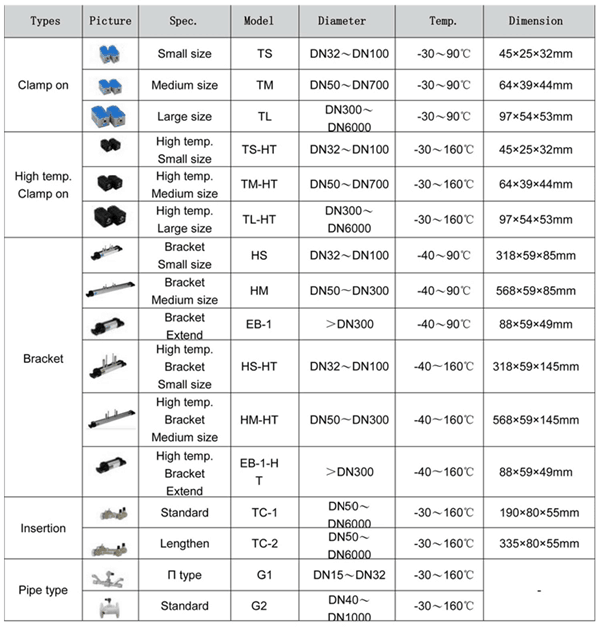

Clamp-on Flow Sensors

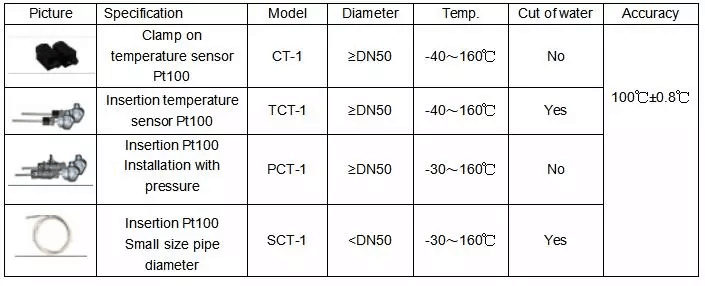

Temperature Sensors

Order Guide

| Code | Transmitter | Sensor | Diameter DN( mm) | Pipe material | Pressure Mpa | Cable length m | Temp. sensor | SD card |

| SI-3403 | TS | DN XX | 0 Carbon steel | XX Mpa | XX m | None | 0 YES | |

| Wall Mounted type | TM | 1 Stainless steel | CT-1 | 1 NO | ||||

| TL | 2 Cast iron | TCT-1 | ||||||

| TS-HT | 3 Glass fiber | PCT-1 | ||||||

| TM-HT | 4 PVC | SCT-1 | ||||||

| TL-HT | 5 Cement | |||||||

| TC-1 | 6 Others | |||||||

| TC-2 | ||||||||

| G |

Example: SI-3403 + TM + DN300 + 0 + 1.6 MPa + 10m + PCT-1

Means: Standard configuration = SI-3403 (transmitter) + TM + 5m cable + Steel belt (DN200) + Couplant (1pc)

Applications

The unique non-invasive measurement method of clamp-on ultrasonic flowmeters enables accurate flow measurement without disturbing the flow of fluids within pipelines.

Clamp-on ultrasonic flowmeters have a wide range of applications, including but not limited to the petrochemical, water treatment, power, and metallurgical industries.

- Monitoring the flow of raw water, treated water, and wastewater at water plants optimizes water resource utilization and ensures environmental compliance.

- Suitable for measuring impure liquids (such as sewage and seawater) without pressure loss and long-term maintenance-free operation.

- Measuring the flow of corrosive chemicals such as acids and alkalis to minimize leak risks.

- In the food and beverage industry, they are used for batching and filling control, ensuring compliance with hygiene standards and preventing cross-contamination.

- In the pharmaceutical industry, they monitor the flow rate of high-purity water systems to meet sterile environments and GMP regulations.

- In heating, ventilation, and air conditioning (HVAC) systems, they optimize cooling water flow management and reduce energy consumption.

- In power plants (nuclear, thermal, and hydropower), they are used for cooling water and heat transfer flow monitoring.

- Monitoring wastewater discharge supports environmental compliance and pollution source tracing. Ultrapure water and process cooling water flow control ensures cleanroom production stability.

- Pipeline leak detection optimizes urban water supply and drainage system management.

Technical Support

The Clamp-on Ultrasonic Flow Meter, with its unique non-invasive design, revolutionizes flow measurement. Compared to traditional insertion or built-in flow meters, the clamp-on ultrasonic flow meter requires no modification or disruption to the pipeline; it can simply be installed externally to achieve accurate flow measurement.

Sino-Inst clamp-on ultrasonic flowmeter has a wide range of applications and is suitable for various fluid pipeline systems, including water, oil and other media. It not only improves flow measurement accuracy and efficiency, but also greatly facilitates fluid management.

If you need to purchase a Clamp-on Ultrasonic Flow Meter or have any technical questions, please feel free to contact us.

-1.jpg)