The 3-wire RTD PT100 is the most common of all wiring types used in industrial temperature measurement. Two leads are connected to one end of the thermal resistor temperature sensing element and one lead is connected to the other end. This lead form is called a three-wire system. Many instruments use this connection method, including temperature transmitters, temperature controllers, panel displays, and data loggers.

Our Sino-Inst’s RTD PT100 Temperature Sensor, 3-wire system, supports customization. Includes: temperature range, insertion depth, connection thread, cable length.

Features

RTD PT100 technical parameters

| Temperature measurement range: | -200-400℃ |

| Probe diameter: | Φ 6 / φ5mm or customized |

| Installation method: | fixed / movable screws |

| Lead length: | generally 2 meters, can be customized length(special lead) |

| Wiring method: | wiring fork |

| Sensing device: | PT (platinum) |

| Probe length: | 5cm/10cm/15cm/20cm or customized |

| Resistance change: | 0.3851Ω/℃ |

| Screw specification: | M8*1.0 or customized |

| Lead connection method: | three-wire |

| Casing material: | stainless steel |

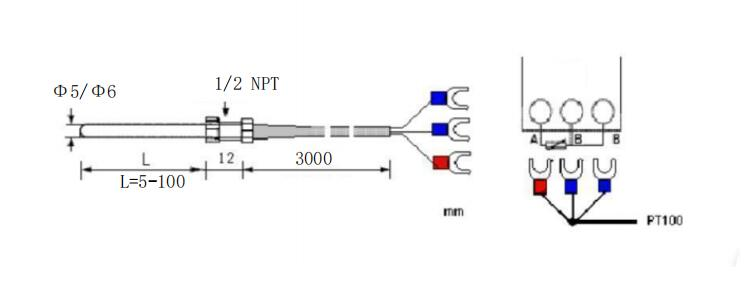

3 Wire RTD PT100 Dimensions

All dimensions of the PT100 resistance thermometer are customizable, including probe diameter, length, thread type, cable, and wiring configuration.

3 Wire PT100 Connection Diagram

The PT100 platinum resistance sensor has three leads, which can be represented by A, B, and C. The following relationships exist between the three leads: the resistance between A and B or C is approximately 110 ohms at room temperature, and the resistance between B and C is 0 ohms. B and C are directly connected internally, and in principle, there is no difference between B and C. However, they must be connected in practical applications. You cannot connect only two wires.

PT100 Sensor End:

The PT100 thermistor has three leads. The standard color coding for these three wires is:

- One red wire: labeled A, connected to one end of the platinum resistor.

- Two white wires: labeled B and C, both connected to the other end of the platinum resistor.

Note: Internally, B and C are short-circuited together and connected to the opposite end of the red wire.

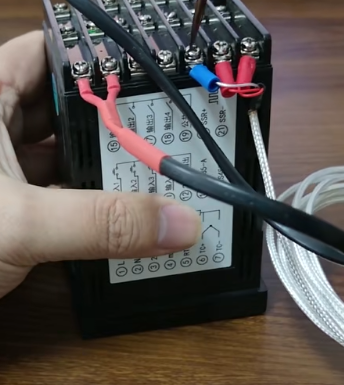

Display Instrument/Transmitter/PLC Module End (Receiving End):

The PT100 input of the instrument usually has three terminals or connection points. Their standard symbols (or equivalent meanings) are:

- A (or “+”, “Exc+”, “Ref+”, etc.)

- B (or “-“, “Sig+”, “P-“, etc.)

- C (or “Ref-“, “S-“, “Com”, etc.)

Wiring Method:

- Red wire (A from PT100) → Connect to instrument terminal A (or “+”, “Exc+”, “Ref+”)

- First white wire (B from PT100) → Connect to instrument terminal B (or “-“, “Sig+”, “P-“)

- Second white wire (C from PT100) → Connect to instrument terminal C (or “Ref-“, “S-“, “Com”)

Three lead methods for thermal resistors: 2-wire system – 3-wire system – 4-wire system

Why does PT100 have 3 wires?

The reason why the RTD PT100 uses a three-wire system is to eliminate the measurement error caused by the resistance of the connecting wires.

This is because the circuit used to measure thermal resistance is generally an unbalanced bridge. The thermal resistor is an arm resistor of the electric bridge, and its connecting wire (from the thermal resistor to the central control room) also becomes part of the bridge arm resistor. This portion of resistance is unknown and changes with ambient temperature. causing measurement errors.

Using a three-wire system, connect one wire to the power end of the bridge. The remaining two are connected to the bridge arm where the thermal resistor is located and the bridge arm adjacent to it. This eliminates measurement errors caused by wire line resistance. In industry, the three-wire connection method is generally adopted.

What is the resistance of PT100 3 wire?

The resistance value of PT100 temperature sensor is 100Ω at 0℃, and the resistance change rate is 0.3851Ω/℃.

More Featured Temperature Sensors and Measurement Solutions

The resistance thermometer converts resistance into a temperature signal. Therefore, the resistance thermometer can be equipped with Pt100 when measuring process temperature. RTD Pt100 can be connected to the transmitter using 2-wire, 3-wire, or 4-wire systems. The three-wire connection is the most common of all wiring types used in Pt100 temperature measurements.

We, Sino-Inst, manufacture and supply various sizes of thermocouples, RTDs and other temperature sensors and transmitters. Support customization and OEM. If you have relevant purchasing needs or technical questions, please feel free to contact us!

RTD PT100 - 3 Wire - Manufacturer Support Customization

The 3-wire RTD PT100 is the most common of all wiring types used in industrial temperature measurement. Two leads are connected to one end of the thermal resistor temperature sensing element and one lead is connected to the other end. This lead form is called a three-wire system. Many instruments use this connection method, including temperature transmitters, temperature controllers, panel displays, and data loggers.

Product SKU: RTD PT100 - 3 Wire - Support Customization

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 29.00

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)