Bimetallic Stem Thermometers are field instruments for measuring medium and low temperatures. They can directly measure the temperature of liquids, steam, and gases within the -80°C ~ +600°C range in various production processes. Simple structure, durable and low cost.

Bimetallic thermometers are corrosion-resistant and vibration-resistant, intuitive and easy to read, safe, reliable, and durable. When used with a thermowell, they can be used in environments subject to vibration or shock. Sino-Inst bimetallic thermometers are widely used in the petrochemical and chemical industries. Electrical contacts can also enable long-distance transmission of temperature signals.

What is a bimetallic stemmed thermometer?

A bimetallic thermometer consists of two metals with different coefficients of thermal expansion. These metals detect temperature changes. When the temperature varies, the two metals expand at different rates, causing the pointer to deflect. This deflection indicates the temperature.

Structure and design of a bimetallic stemmed thermometer

The rod-type design of bimetallic rod thermometers is primarily reflected in their probe construction. The probe connects the temperature-sensing element to the dial assembly. It transmits temperature changes to the pointer.

Design Features of Probe Rods

Customizable Length. Meets extension requirements for diverse installation scenarios.

Material and Craftsmanship. Features a corrosion-resistant material housing. Suited for complex industrial field conditions.

Protection Rating. Achieves IP55 protection rating. Withstands high temperatures (≤200°C) and harsh environments.

Installation Methods

Bimetal thermometers offer multiple connection types, including axial, radial, and universal.

Axial Type: The dial connects perpendicularly to the probe (T-type structure). Suitable for sidewall mounting.

Radial Type: The dial connects parallel to the probe (I-type structure). Facilitates front-facing readings.

Universal Type: The connection angle between the dial and probe can be freely adjusted. Adaptable to complex installation environments.

Working principle of bimetallic stemmed thermometers

The operating principle of a bimetallic thermometer is based on the differing thermal expansion properties of two distinct metal strips. These strips are typically coiled into a spiral shape and housed within a protective sheath.

One end of the bimetallic strip is welded in place, termed the fixed end. The opposite end is the free end, which connects to components like the pointer shaft, movement, and pointer.

When ambient temperature changes, the free end deforms and deflects. The movement then drives the pointer to rotate, displaying the measured temperature on the dial.

The deflection angle Φ of the free end of a spiral bimetallic strip when heated can be expressed by the following formula:

Φ = 360/πk(t2 – t1) * L/a

In the formula:

- Φ is the deflection angle.

- k is a constant.

- t2-t1 is the temperature change value.

- L is the effective elongation length of the bimetallic strip.

- a is the thickness of the bimetallic strip.

Applications and benefits of bimetallic stemmed thermometer

Applications

- Petroleum

- Food

- Chemical and Metallurgical Industries

- Textiles

- Heating System Monitoring

- Automatic Control

- Refineries

- Fuel Oil Burners

Benefits

- Mercury-free design. It can replace industrial glass liquid thermometers in many applications.

- Accurate and reliable. Bimetal thermometers use mechanical transmission, requiring no external power source.

- Simple construction. Compact size facilitates installation and maintenance.

- High durability. Manufactured from stainless steel or other corrosion-resistant materials.

- Wide measurement range. Capable of measuring temperatures from low to high.

- Cost-effective. Low production costs and simple maintenance. Suitable for users with limited budgets.

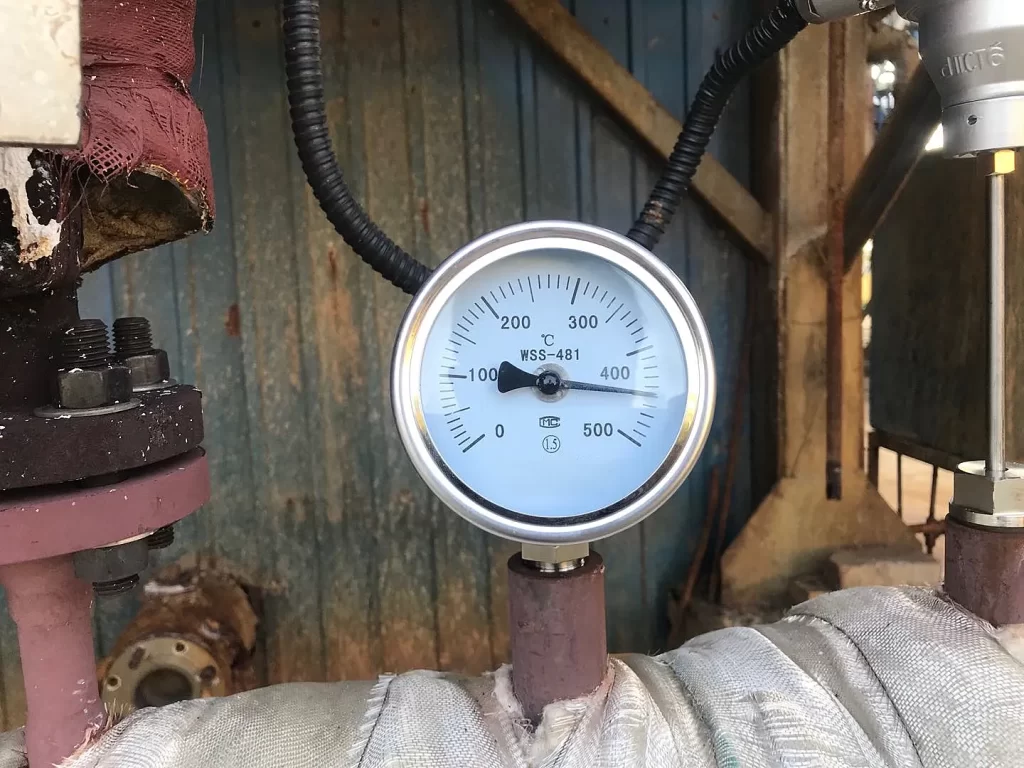

What temperature should bimetallic stemmed thermometer be set to?

Common scale ranges for bimetallic thermometers include: -80~40℃,-40~80℃,0~50℃,0~100℃,0~150℃,0~200℃,0~300℃,0~400℃,0~500℃, etc. Should be selected based on actual measurement requirements and the instrument’s accuracy class.

Selecting Gauge Class:

- Class 1 bimetallic thermometers measure from -80°C ~ +500°C.

- Class 2 bimetallic thermometers measure from -50°C ~ +300°C.

- Class 3 bimetallic thermometers measure from -30°C ~ +250°C.

Measurement Position:

The sensing probe should be inserted at least 40mm into the liquid or gas. The measurement point should be positioned at the center of the object being measured, avoiding contact with surfaces.

Environmental Requirements:

Avoid mechanical vibration, impact, or high temperatures. This prevents damage to the instrument.

How deep should bimetallic stemmed thermometer be inserted?

The insertion depth of bimetallic thermometers must be determined based on the specific application scenario. The common range is 75mm to 1000mm.

Differences in Measured Medium Types

When measuring liquids or gases, the temperature-sensing tube must typically be fully immersed in the medium. Ensure the bimetallic strip maintains full contact with the medium.

For solid media measurements where the instrument interface is distant from the medium (e.g., positioned above the container), the insertion depth may reach 1000mm or longer.

Equipment and Process Requirements

When measuring pipes, a depth of 75mm is sufficient for smaller inner diameters. If accommodating the length of connecting bases or flanges, the insertion depth must be increased accordingly.

When measuring containers, if installed at the top, the temperature probe must be immersed at least 75mm into the medium.

Protective Tube Length

When the protective tube length is less than 300 mm, the insertion depth shall not be less than 70 mm. When greater than 300 mm, the insertion depth shall not be less than 100 mm.

Calibrating bimetallic thermometers

Before calibrating the thermometer, we must remove the bimetallic thermometer from the equipment. Ensure there are no external disturbances. Additionally, calibration should be performed in a laboratory environment with stable temperatures. Avoid external disturbances such as vibration or pressure.

The calibration methods for bimetallic thermometers primarily include the ice-water method and the high-temperature method (boiling water method).

Ice Water Method

1. Fill a container with ice cubes and add cold distilled water until the ice is completely submerged, forming a slushy mixture.

2. Insert the thermometer probe vertically into the ice-water mixture. Ensure it does not touch the container walls or bottom.

3. After 30 seconds, the thermometer reading should stabilize at 0°C (32°F). If the reading deviates beyond the acceptable range, adjust the thermometer or record the deviation value.

High-Temperature Method

1. Heat distilled water to boiling.

2. Insert the thermometer probe vertically into the boiling water, again avoiding contact with the container walls or bottom.

3. Once the temperature stabilizes, the reading should be 100°C (212°F). If the deviation exceeds the acceptable range, adjust the thermometer or record the deviation value.

More Temperature Measurement Solutions

Bimetallic rod thermometers are field-mounted instruments for measuring low to medium temperatures. They can directly measure the temperature of gases, steam, and liquids. They feature clear readings and good mechanical strength.

Bimetal thermometers are commonly used instruments in industrial temperature measurement. They operate on the principle that different metals have different thermal expansion coefficients. They feature a simple structure and are easy to install. And they are utilized in numerous industrial settings.

Sino-inst offers a wide range of bimetallic thermometers, including axial, radial, and universal types. We support customization for various mounting dimensions. If you have any purchasing needs or technical questions, please contact our sales engineers!

-1.jpg)