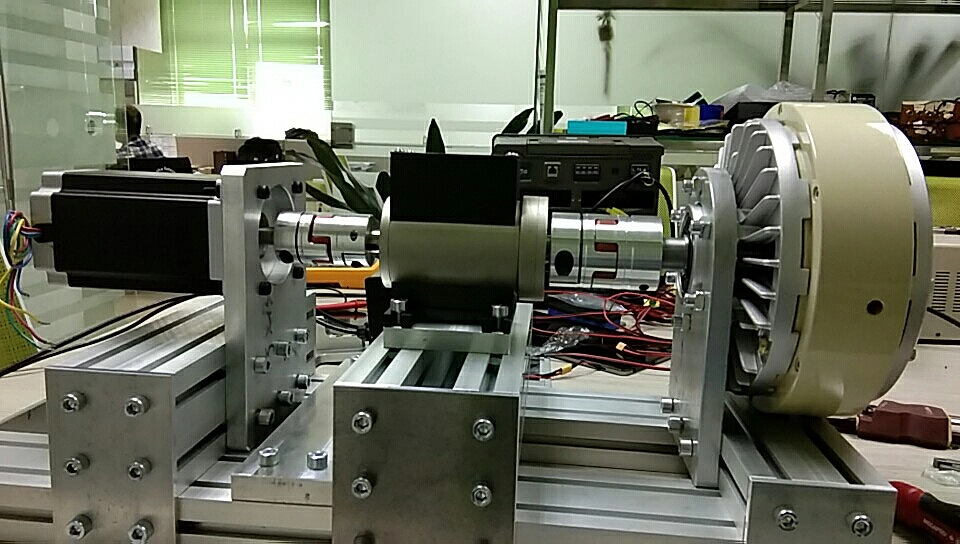

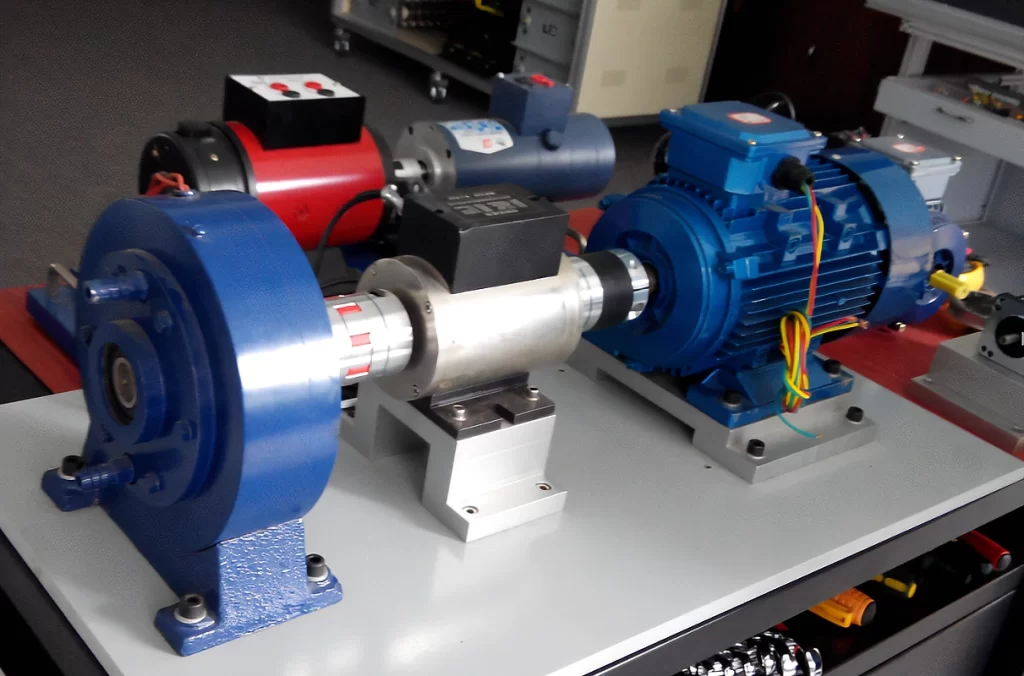

Motor torque testing ensures proper motor operation and the safety of mechanical equipment. Torque sensors have a wide range of applications in motor testing and measurement.

Motor torque

Motor torque refers to the output torque of the motor, which is the product of the motor output power and the speed. The size of the motor torque is related to the motor load and the performance of the motor itself.

Generally speaking, the greater the motor torque, the higher the motor output power and efficiency. Measuring motor torque is an important means to evaluate the performance and working status of the motor.

Motor torque measurement method

1. Dynamic measurement

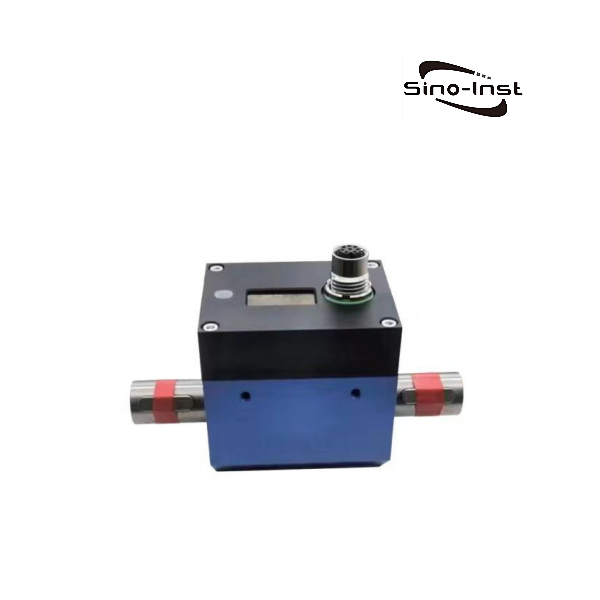

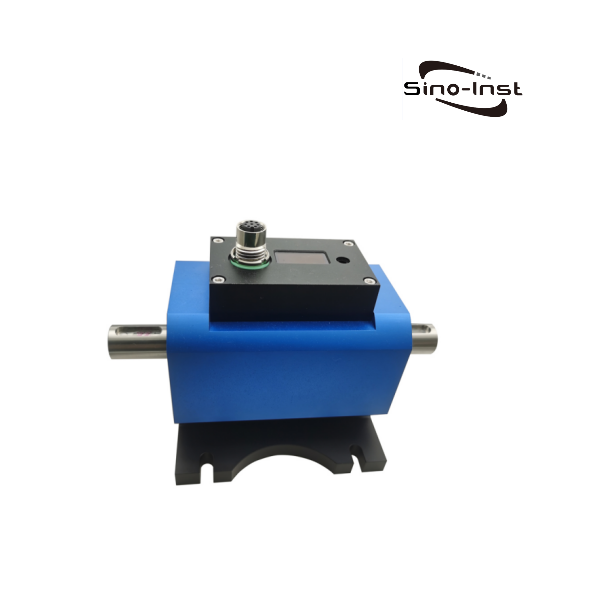

The dynamic measurement method is to calculate the torque value of the motor by measuring the torque of the motor during acceleration or deceleration. Usually, torque sensors, speed sensors and data collectors are required.

The specific measurement steps are as follows:

(1) Install the torque sensor on the motor shaft to measure the torque of the motor.

(2) Install the speed sensor on the rotor of the motor to measure the speed of the motor.

(3) Collect the data of the torque sensor and speed sensor into the computer through the data collector.

(4) Use a computer to process and analyze the collected data to obtain the torque value of the motor.

Sino-Inst’s dynamic torque sensor can also measure speed and torque at the same time.

The dynamic measurement method has high measurement accuracy, fast measurement speed, and a wide application range. However, it requires professional measurement equipment and technology. Attention should be paid to safety issues during the measurement process.

2. Static measurement

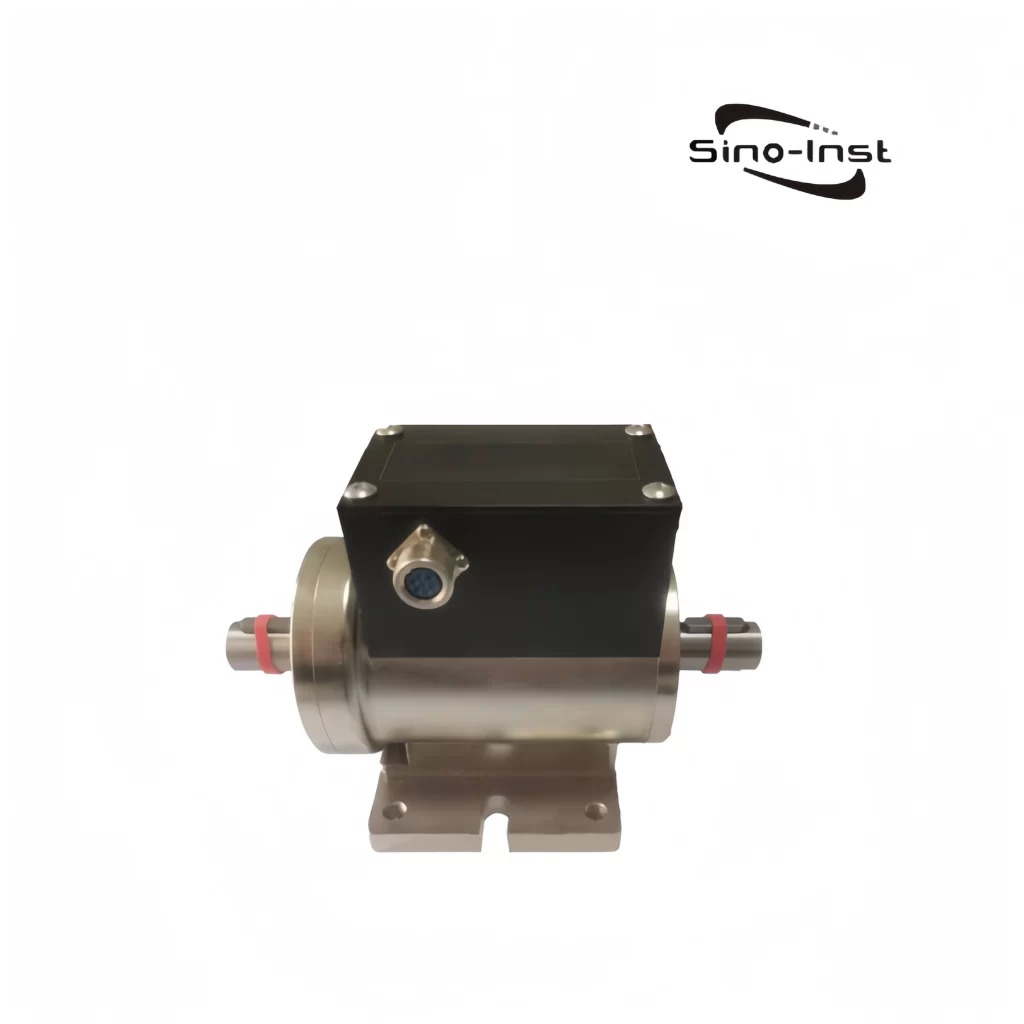

The static measurement method is to calculate the torque value of the motor by measuring the torque of the motor in a static state. The required equipment includes a torque sensor, a support device and a data collector.

The specific measurement steps are as follows:

(1) Fix the motor on the support device to keep the motor in a static state.

(2) Install the torque sensor on the motor shaft to measure the torque of the motor.

(3) Collect the data of the torque sensor into the computer through the data collector.

(4) Use a computer to process and analyze the collected data to obtain the torque value of the motor.

Static measurement is simple to operate, safe and reliable, and has a wide range of applications. However, measurement accuracy is affected by the support device and environmental conditions. Careful control of measurement conditions and environment is essential.

Applications of Motor Torque Measurement

Motor torque measurement can be used to test motor performance parameters such as power, efficiency, and response time.

Using a torque sensor to monitor the motor can promptly detect abnormalities, providing important evidence for motor fault diagnosis.

Furthermore, using a torque sensor enables high-precision motor speed control. This can be used to optimize motor control systems and improve the safety of mechanical equipment.

More Torque Measurement Solutions

Torque is a crucial measurement variable in the mechanical field and is closely intertwined with many applications. Motors require precise torque measurement. Modern engines require higher speeds to improve mechanical performance and efficiency, which also requires highly reliable torque measurement.

Torque measurement technology is constantly evolving. Sino-Inst offers a variety of dynamic and static torque sensors. If you require motor torque measurement or have any technical questions, please feel free to contact our sales engineers!

-1.jpg)