Paint flow meters are necessary component of various industrial environments to measure and control the flow of paint, adhesives, and coatings. In applications like automotive, industrial manufacturing or commercial painting demand metering competent of handling thick, “sticky” and often abrasive materials.

Additionally, Paint flow meters must be able to resist pump pulsations at often high line pressures due to the viscous nature of the flows. Simultaneously, providing flow measurement with a high degree of accuracy is vital for a particular application. This article looks into the types, benefits, and key applications of paint flow meters.

Selecting the Right Paint Flow Meter: Basic Requirements

Featured Types of Paint Flow Meters

Several types of flow meters are used for measuring paint flow, each offering unique advantages:

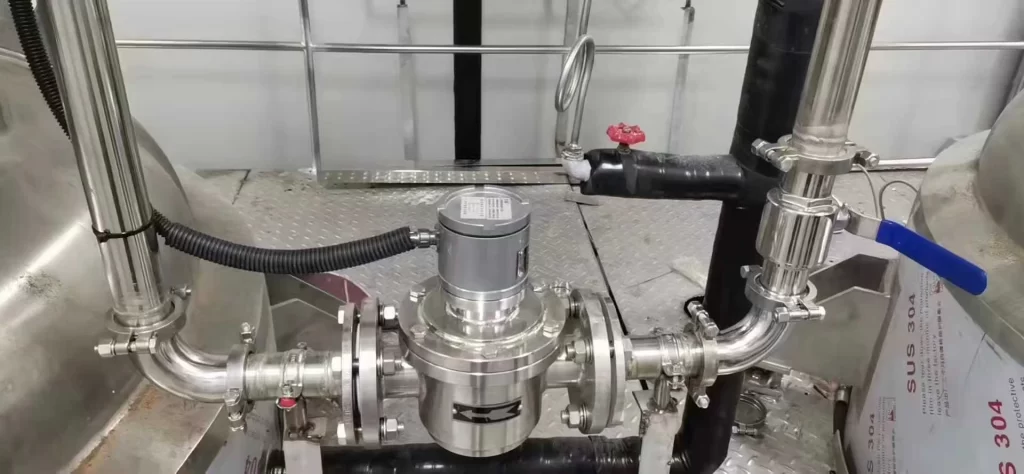

1. Coriolis Flow Meters

Coriolis flow meters measure the mass flow rate of paint by detecting changes in fluid motion. They offer high precision and are ideal for high-viscosity paints.

Coriolis mass-flow meters provide accurate fills without contamination problems on fillers running a variety of paint colors and textures.

Sino-Inst’s Coriolis mass flow meters can meet 0.1% high accuracy, 10MPa high pressure customization, DN1 micro flow customization (as low as 100g/h).

Behind Principle:

- This is an absolute measurement of quantity that is unaffected by changing fluid properties, such as viscosity or density. In addition, changing fluid process conditions, such as temperature or pressure, do not introduce additional measurement uncertainty.

- Coriolis meters eliminate the need for density compensation-correction systems to adjust the actual measured volume flows to standard, or reference conditions, because a direct mass measurement has no need for density compensation. In fact, the multi-variable measurement principle of Coriolis technologies also provides a measure of fluid density as a secondary output.

- A Coriolis meter requires two components: an in-line fluid-flow sensing element and an electronic unit with a transmitter that interprets the signals from the sensor and converts these signals into usable outputs, usually pulse, 4 to 20 mA analog, and digital outputs.

- Mostly, Coriolis meters do not require special installation procedures, flow straighteners or special lengths of straight pipe to correct the fluid-flow profile. Eliminating these piping requirements reduces the size and cost of many Coriolis-based flow measurement systems.

2. Positive Displacement (PD) Flow Meters

PD flow meters measure fluid volume by capturing and releasing fixed amounts of paint through rotating components. Oval gear flow meter is a kind of PD flow meter for viscous liquid like paint. These meters are suitable for measuring thick or multi-component paints.

Behind Principle:

- When the measured liquid enters the oval gear flowmeter through the pipeline, the pressure difference generated at the inlet and outlet drives a pair of gears to rotate continuously.

- The liquid measured by the crescent cavity is continuously transported to the outlet. The product of the number of revolutions of the oval gear and four times the displacement each time is the total flow of the measured liquid.

- When measuring liquids with high viscosity, the leakage from the gap between the gear and the metering space is small. Therefore, the greater the viscosity of the measured liquid, the smaller the leakage error.

- The more favorable it is for measurement, the higher the measurement accuracy. It can be said that the oval gear flowmeter is the best choice for measuring the flow of high-viscosity liquids.

Sino-Inst’s High Viscosity Oval Gear Flow Meter is a popular choice for medium to highly viscous liquids including paints and coatings. Some of the key specifications are:

- High measurement accuracy: 0.2 and 0.5;

- The mechanism is simple, sturdy and reliable.

- Particularly suitable for measuring medium with high viscosity

- Easy to install. There is no need for straight pipe sections before and after the flowmeter, and there is no need to install straight pipe sections.

- In order to prevent the gear of the flowmeter from being jammed by impurities, a filter must be installed upstream of the flowmeter.

- It can be mechanical, without power requirements; it can also be intelligent, with signal output.

3. GF Gear Flow Meter – Perfect for low flow

GF Gear Flow Meter is a new type of volumetric flow meter. It is mainly used for measuring and controlling small flows. It is available in PTFE, aluminum alloy, 304 stainless steel, and 316 stainless steel.

- High pressure resistance (1.0-45MPa)

- High and low temperature resistance (-196°C-200°C)

- Can measure various viscous media

- High precision and repeatability

- Pulse output/analog output optional

- Wide range ratio (1:100)

- Wide measurement range

- Strong anti-corrosion and anti-fouling ability (acid-alkali liquid)

Fundamental Benefits of Paint Flow Meters

1. Better Accuracy

Flow meters ensure precise measurement and consistent paint application, reducing variations in coating thickness.

2. Cost Savings

By optimizing paint usage, these meters minimize waste and reduce material costs, making painting processes more efficient.

3. Enhanced Quality Control

Proper flow measurement prevents issues like uneven coating, streaks, or excess buildup, improving the final product’s appearance and durability.

4. Process Automation

Many modern paint flow meters integrate with automated systems, allowing for better process control and reducing manual intervention.

5. Maintenance and Efficiency

Flow meters help detect irregularities in paint flow, alerting operators to potential clogs, leaks, or equipment malfunctions before they cause major issues.

Applications of Paint Flow Meters

1. Automotive Industry

Car manufacturers rely on precise paint flow control to ensure even coating on vehicles, reducing rework and defects.

2. Aerospace Coating

Aircraft painting requires extreme precision to ensure proper adhesion and weight control, making flow meters indispensable.

3. Industrial Machinery and Instrumentation

Large machinery and equipment require uniform coatings to protect against corrosion and wear, making accurate flow measurement critical.

4. Furniture and Wood Coating

Manufacturers use paint flow meters to apply smooth and consistent finishes to wooden furniture and flooring products.

5. Printing and Packaging

Flow meters help regulate the application of inks and coatings in high-speed printing and packaging processes.

More Flow Measurement Solutions

- Knowing Paint Flow Meters – Choose the Right One!

- Comprehensive Guide On Chlorine Flow Meters

- How To Calculate Pressure From Flow Rate And Vice Versa

- Non-Contact Flow Meters: An Advanced Approach To Fluid Measurement

- Relationship Between Pressure And Flow Rate: Key Insights

- High Accuracy Flow Meters: Technology, Applications, And Benefits

- Right Flow Meter For Molasses

- Mechnical & Digital Kerosene Flow Meters

- Understanding Asphalt And Bitumen Flow Meters

A paint flow meter is an essential tool for industries that rely on accurate and efficient paint application. Whether for automotive, aerospace, or industrial use, these devices ensure consistency, cost savings, and improved product quality.

By choosing the right type of flow meter for your needs, you can optimize your painting process and achieve superior results. Please feel free to contact our Sino-Inst sales engineers!

-1.jpg)