Industrial Temperature Monitoring System can detect and record temperature changes. Temperature sensors are installed on key equipment, pipelines, furnaces, etc. in the factory to monitor temperature changes during equipment operation in real time.

The data detected by the sensor can be transmitted to the inspection meter, recorder, and even to the cloud platform through the gateway. Managers can manage and control temperature more efficiently.

Next, we will share the simplest Industrial Temperature Monitoring System setup.

First, you need to select the temperature sensor to be used.

Then, you need to select a monitoring device or monitoring software.

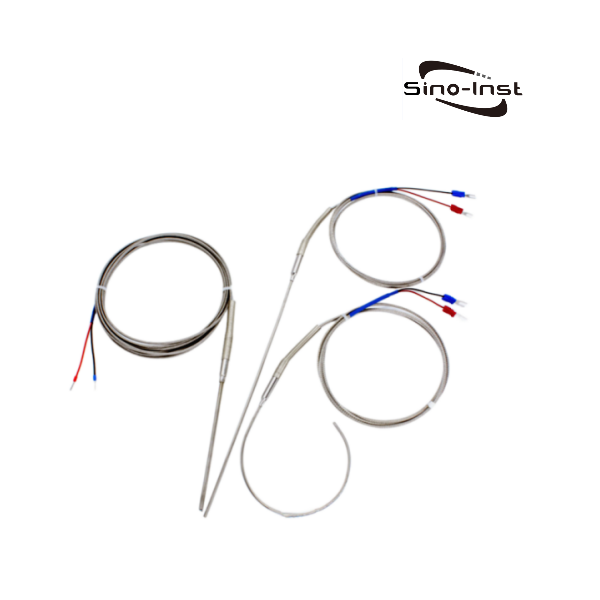

So, let’s take a closer look at the temperature sensor. We can choose thermal resistors, thermocouples, and temperature transmitters. We can simply distinguish them:

- Thermocouples, referred to as TC, work on the principle of outputting a linear millivolt signal as the temperature changes. The instrument amplifies the signal and converts it into a temperature signal.

- Thermal resistors, referred to as RTD, work on the principle of linear changes in resistance value as the temperature changes.

- Temperature transmitters can convert thermocouple mV voltage signals or thermal resistor resistance value signals into 4-20mA standard signals for automation system control.

Featured Temperature Sensors

OK. After laying out the temperature sensor, we need to consider the reasonable monitoring and control of the acquired temperature signal.

For example, do we simply need to configure a display instrument next to the temperature sensor to display the temperature value in real time?

Or do we need to view the data of multiple temperature detection points in a monitoring room?

Or do we need to view the temperature data far enough away? Do we plan to use wired or wireless methods?

Once we have clarified our needs, we can find suitable monitoring instruments or software.

First, we can take a look at the temperature patrol meter.

Temperature Patrol Meter

The temperature patrol meter is an industrial measuring digital display instrument, which is often used in conjunction with temperature sensors and temperature transmitters. The temperature patrol meter can patrol and monitor and display the measured temperature parameters in each channel.

It is suitable for scenarios where multiple points of temperature need to be centrally monitored at the same time and alarm control, transmission output and communication are required.

The input signal of the temperature patrol meter can be selected by setting: thermocouple, thermal resistor, DC current or DC voltage signal.

Among them, the thermal resistor can receive temperature sensors such as Pt100/Cu100/Cu50/BA1/BA2/G53. Thermocouples can receive temperature sensors such as K/S/R/B/N/E/J/T.

DC current can receive (4-20) mA/(0-10) mA/(0-20) mA signals.

The DC voltage can receive (0-5)V, (1-5)V) signals or (mV signals (+100 ~ -100)mV.

It can basically meet most of the requirements for the use of temperature inspection instruments.

Can Temperature Patrol Meter be used as a data acquisition platform?

First of all, multi-channel signal input is equivalent to providing the conditions for data acquisition. It is necessary to be able to collect signals such as on-site temperature or pressure into the register, and the built-in communication function can transmit the collected data on site to the host computer such as PLC or display screen.

After the host computer collects these data, it can be used for storage or data analysis and other operations. So from this level, the temperature patrol meter can be used as a data acquisition platform.

The advantage of using the temperature patrol meter as a collection platform is that the instrument can collect analog data of up to 80 channels. It can save a large part of the space for equipment installation. So it can be transmitted to the host computer for data operation. And the personnel on site can also view the data of each channel in real time.

Paperless Recorder

Patrol meters and paperless recorders have many similarities to a certain extent. Paperless recorders also have unique advantages.

The paperless recorder processes various input signals that need to be monitored and recorded at the industrial site through a high-performance 32-bit ARM microprocessor. , such as the flow signal of the flow meter, the pressure signal of the pressure transmitter, the temperature signal of the inspection instrument, the thermal resistor and the thermocouple, etc.

On the one hand, it is displayed in various forms on the large-screen LCD screen. On the other hand, the data of these monitoring signals is stored in the large-capacity storage chip built into the machine. So that data and graphics can be directly queried, flipped and printed on this recorder.

For example, our paperless recorder can receive the following temperature signals:

- Current: 0~20mA, 0~10mA, 4~20mA, 0~10mA square root, 4~20mA square root

- Voltage: 0~5V, 1~5V, 0~10V, ±5V, 0~5V square root, 1~5V square root, 0~20 mV,

- 0~100mV, ±20mV, ±100mV

- Thermocouple: Pt100, Cu50, Cu53, Cu100, BA1, BA2

- Linear resistance: 0~400Ω

- Thermocouple: B, S, K, E, T, J, R, N, F2, Wre3-25, Wre5-26

Functionally:

- Temperature Patrol Meter displays the on-site data and outputs the signal to other instruments for control. On this basis, the paperless recorder can also print out all data records.

- Temperature Patrol Meter does not need to have a storage function. But paperless recorders must have a storage function.

- Temperature Patrol Meter generally has an LCD or LED digital display, and some models have an LCD graphic display. But paperless recorders usually have a graphic LCD or even a color graphic LCD.

Wireless transmission-cloud platform monitoring

For those who need to monitor the temperature system over a longer distance, you can consider transmitting the factory temperature signal to the network wirelessly. You need to build a complete Internet of Things (IoT) architecture.

For example, you can process the following in sequence:

For example, you can process the following in order:

- Temperature sensor

- Wireless signal

- Gateway

- Ethernet/4G/5G

- Cloud platform

- Computer/mobile phone monitoring

This involves local network operators, customization of cloud platform software, and customization of mobile phone software. Therefore, we generally recommend that you find a suitable service provider in your local area to build a wireless Industrial Temperature Monitoring System for you.

More Temperature Measurement Solutions

Industrial Temperature Monitoring System can help enterprises better control and manage temperature. Thus saving energy, reducing costs, improving safety, improving work efficiency, and providing better services to customers.

Sino-Inst supplies various types of temperature sensors and secondary instruments that can provide real-time temperature data. So that enterprises can better control and manage temperature. If you need to build an Industrial Temperature Monitoring System, please feel free to contact our sales engineers!

-1.jpg)