- Range: 50-10KNm;

- Shortest installation length;

- Integrated double flexible disc coupling coupling;

- No bearing, eliminating the influence of bearing friction;

- Non-contact;

- High speed 30K RPM;

- Small installation angle;

CL1-106 Flange Disc Dynamic Torque Sensor Technical Parameters

| Range | 50-10KNm | Repeatability | ±0.02% | ||

| Accuracy | ±0.1, ±0.2%FS | Supply voltage | 12~24VDC | ||

| Zero-point temperature effect | ±0.02%FS | Supply current | Less than 100mA | ||

| Full-scale temperature effect | ±0.02%FS | Electrical connection | 8-Pin | ||

| Compensated temperature range | -10-60℃ | Overload protection | 200%FS | ||

| Operating temperature range | -20~75℃ | Material | Shaft material 17-4PH stainless steel, housing is aluminum | ||

| Torque output | 10±5kHz(5V amplitude), 0-±5VDC, 0-±10VDC, 0-5-10VDC, 4-12-20mA, 0-5V, 0-10V, 4-20mA, RS485, RS232, CAN, etc. | ||||

| Options | Installation | Axial error ±0.2mm, angular error 0.4° | |||

| Rotation speed measurement | 60 pulses/circle 4-20mA, 0-5VDC, 0-10VDC, RS485, RS232, CAN, etc. | ||||

Dimensions

| Nm | A | B | b | C | D | E | F | G | H1 | H2 | J | M | L | N | h1 | h2 | h3 | P |

| 50,100,200 | 152 | 119 | 114 | 84 | 57 | 110 | 45 | 50 | 209 | 133 | 6-φ14 | 6-M8 | 13 | 20 | 15 | 1.5 | 2.7 | 6-φ8.2 |

| 5,001,000 | 174.6 | 139 | 134 | 101.5 | 75 | 130.4 | 51 | 54 | 232.2 | 144 | 8-φ17 | 8-M10 | 15.5 | 18 | 17 | 2 | 4.2 | 8-φ10.5 |

| 20,003,000 | 210 | 173 | 168 | 130 | 90 | 154 | 53 | 58 | 266 | 161 | 8-φ19 | 8-M12 | 15 | 20 | 18 | 2.5 | 4.2 | 8-φ12.5 |

| 5000 | 233 | 201 | 196 | 155.5 | 110 | 180 | 65.8 | 68 | 292 | 175.5 | 8-φ22 | 8-M14 | 20 | 22 | 20 | 2.8 | 4.2 | 8-φ14.5 |

| 10000 | 286 | 251 | 246 | 196 | 140 | 230 | 79 | 80.5 | 342 | 199 | 8-φ26 | 8-M16 | 22 | 22 | 22 | 3.5 | 4.2 | 8-φ16.5 |

Featured Applications

The bearingless flange disc dynamic torque sensor is a torque sensor that can dynamically measure torque and speed. It can collect torque and speed signals at high speed and high precision, and supports various output methods.

It has a smaller axial size in dynamic torque and a removable measuring shaft, which is suitable for a variety of installation environments. It greatly simplifies the installation steps and also makes the sensor have certain anti-coaxial characteristics.

The torque sampling and signal output rates of the CL1-106 Flange Disc Dynamic Torque Sensor are both above 3000Hz, which can be used in occasions that require high-speed torque acquisition. Output analog or communication torque and speed signals.

Very suitable for test bench applications. Such as engine, dynamometer and electric motor test bench, wheel load simulation test bench, gearbox and pump test bench and other applications. Also mainly used for:

- Detection of output torque and power of rotating power equipment such as motors, engines, internal combustion engines;

- Detection of torque and power of fans, water pumps, gearboxes;

- Detection of torque and power in railway locomotives, automobiles, tractors, aircraft, ships, and mining machinery;

- It can be used for torque and power detection in sewage treatment systems;

- It can be used in process industries and process industries.

Installation

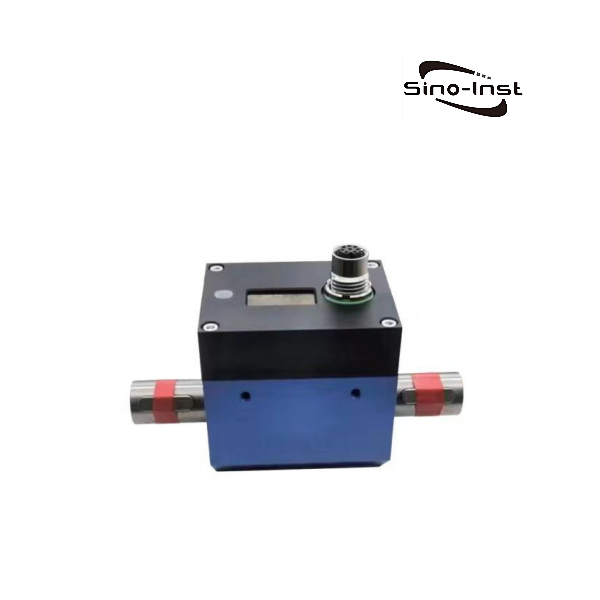

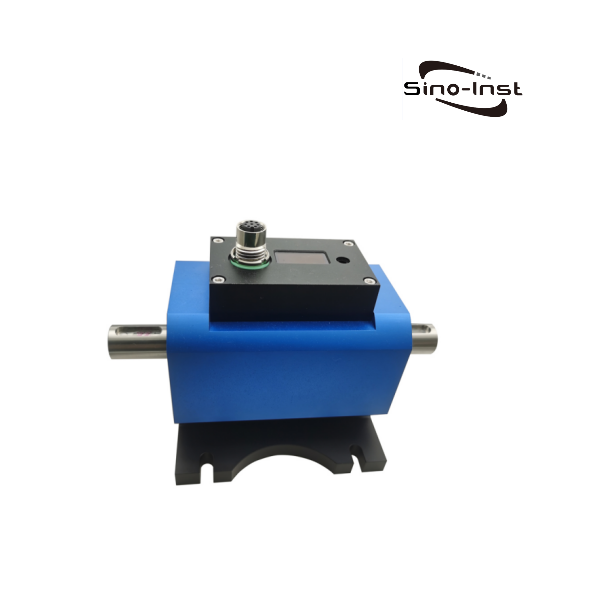

- The dynamic disc torque sensor consists of a stationary housing and a rotating disc;

- The two ends of the rotating disc are connected to the power and load respectively through flange couplings;

- The stationary housing is fixed on the base. Adjust the gap to ensure that there is no contact between the stationary housing and the rotating disc!

Signal output and signal acquisition

(1) Basic forms of torque signal output:

Square wave signal, pulse signal, 0-20mA, 4-20mA, 1-5V, 0-5V, O-10V.

It can be made into voltage analog signal output or current analog signal output (unidirectional, static torque measurement) according to user needs.

(2) Torque signal processing form:

The frequency signal output by the torque sensor is sent to a frequency meter or digital meter to directly read the frequency signal or voltage and current signal proportional to the torque.

The torque and frequency signals of the torque sensor are sent to the secondary instrument of the single-chip microcomputer. Directly display the real-time torque value, speed and output power value and RS232 communication signal. Directly send the frequency signals of torque and speed to the computer or PLD for processing.

More Torque Sensors and Solutions

Sino-Inst is a professional torque sensor manufacturer. Our CL1-106 Flange Disc Dynamic Torque Sensor has a bearingless structure and is maintenance-free and oil-free.

We provide customers with high-precision torque measurement services. Our independently developed series of high-performance torque and speed sensors and supporting measuring instruments have entered the market, and the products have quickly become popular due to their superior performance.

If you need to measure torque and speed, or have related design questions, please feel free to contact us.

CL1-106 Flange Disc Dynamic Torque Sensor - Bearingless

The bearingless flange disc dynamic torque sensor is a torque sensor that can dynamically measure torque and speed. It can collect torque and speed signals at high speed and high precision, and supports various output methods.

Product SKU: CL1-106 Flange Disc Dynamic Torque Sensor - Bearingless

Product Brand: Sino-Inst

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)