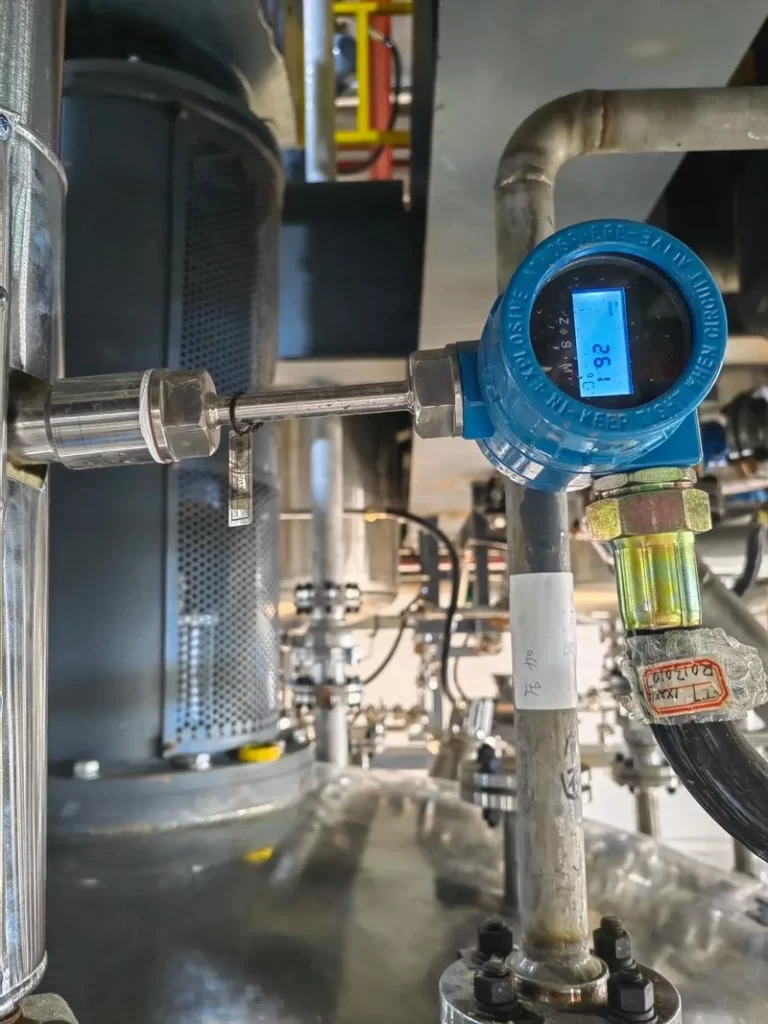

In explosive and flammable industrial environments, safety and operational efficiency are paramount. Temperature monitoring is not only a routine operation but also the cornerstone of safe production. Therefore, explosion-proof temperature sensors are a core component in this field.

Explosion Proof Temperature Sensors offer extremely high accuracy and reliability. They are suitable for industries such as oil and gas, chemical processing, mining, and power generation. They protect personnel and assets while meeting safety standards.

Know about explosion proof temperature sensors

Explosion-proof temperature sensors are temperature sensors with explosion-proof performance. They are designed for use in potentially explosive and flammable environments. Unlike traditional sensors, they have a sturdy fireproof casing. They effectively contain potential internal explosions, preventing them from igniting the surrounding environment.

Our Sino-Inst explosion-proof temperature sensors are designed as resistance thermometers or thermocouples. They are used to measure the temperature of liquids, gases, and solids. They are widely used in traditional industries. Such as the chemical industry, food industry, and crude oil and natural gas extraction.

Advantages

- Outstanding Explosion-Proof Performance

Explosion-proof temperature sensors utilize special explosion-proof designs (such as flameproof and intrinsically safe). This prevents them from generating ignition sources such as sparks and high temperatures. - Adaptable to Harsh Environments

Explosion-proof temperature sensors can operate in environments with high and low temperatures, vibration, and other conditions. - Accurate and Reliable Temperature Measurement

Explosion-proof temperature sensors offer high-precision temperature measurement capabilities. They provide real-time, accurate feedback on ambient or device temperatures. - Compliance with Industry Standards

Strictly adhere to national and international explosion-proof standards (such as Ex certification). They meet the safety regulations of industries such as the petroleum, chemical, and coal mining industries. - Extended Equipment Life

The sensors themselves are rugged, wear-resistant, and age-resistant. They can operate stably and long-term in harsh environments.

Featured explosion-proof temperature sensors

Applications

Explosion-proof temperature sensors can be widely used in various industries.

Petrochemical industry.

Explosion-proof temperature sensors can be used to monitor temperatures at wellheads, oil pipelines, oil storage tanks, and other locations.

Coal and mining industries.

In crushing and grinding processes, they can monitor equipment and material temperatures.

Metallurgy and metal processing.

Explosion-proof temperature sensors can measure the surface temperature of media or equipment in high-temperature environments.

Gas stations.

Explosion-proof temperature sensors can monitor ambient and equipment temperatures. This can ensure the safety of refueling operations

Precautions for using explosion-proof temperature sensors

| Precautions | |

| Explosion-proof level and environment | According to the hazard level and temperature group of the place of use. You can choose the corresponding explosion-proof type. |

| Pre-installation inspection and certification | Check the sensor housing, wiring ports, seals, and other components for integrity. Confirm that the sensor has explosion-proof certification from a recognized agency. |

| Regular maintenance and inspection | Check the sensor housing for damage or rust. Ensure the explosion-proof surface is clean (free of oil, dirt, or dust). Check the wiring port seal for signs of aging or hardening. If it loses its elasticity, replace it with a similar-sized explosion-proof seal. |

| Avoid using beyond the scope | Strictly adhere to the rated parameters of the sensor. |

| Personnel qualifications and training | Installation, operation, and maintenance personnel must receive explosion-proof training. They must be familiar with the equipment’s explosion-proof principles and safety precautions. |

More Temperature Measurement Solutions

RTDs are mostly made of pure metal. Platinum and copper are the most widely used. Nickel, manganese, and rhodium are also being used in RTD manufacturing. Sino-Inst manufactures and supplies a variety of industrial RTDs, primarily the PT100 type.

Armored thermocouples are a new generation of temperature sensors. They are widely used in industries such as metallurgy, petroleum, chemicals, and power generation. They can also serve as the temperature-sensing element for assembled thermocouples.

Temperature transmitters convert temperature changes into a 4-20mA output signal. Our Sino-Inst 4-20mA temperature transmitters are available with PT100, K-type, N-type, and J-type thermocouples.

Sino-Inst offers over 50 industrial temperature sensors and transmitters. These include RTDs, thermocouples, and PT100s, and are also available with a 4-20mA output. If you need to purchase explosion-proof temperature sensors or have any questions, please feel free to contact us.

-1.jpg)