Micro Motion flow meters are among the most trustworthy and advanced flow meter solutions available nowadays. It is Flow Meters for Mass, Volume & Density Measurement owned by Emerson. Micro Motion has released a variety of coriolis tools, led by the elite series meters that offer peak performance in a drainable design.

Known for their unmatchable accuracy and direct mass flow measurement, these devices have become an industry standard. This blog post provides a comprehensive look into micromotion mass flow meters.

Working Principle of Micromotion Mass Flow Meters

Motions of very short duration or length, especially periodic motion, are called micromotion. Micro motion coriolis flow meters are based on the principle of kinematics.

In a Coriolis flow meter, an actuator causes a small tube to vibrate continuously near its natural frequency. When the measured fluid enters the sensor, it is diverted to two parallel measuring tubes (vibrating tubes).

When measuring the flow, the drive coil excites the pipe to oscillate in opposite directions at the natural resonant frequency. Two sensors placed along the pipe measure the deflection of the vibrating tube over time. The time delay between the two sine waves is called the time difference (Delta-T), which is proportional to the mass flow rate.

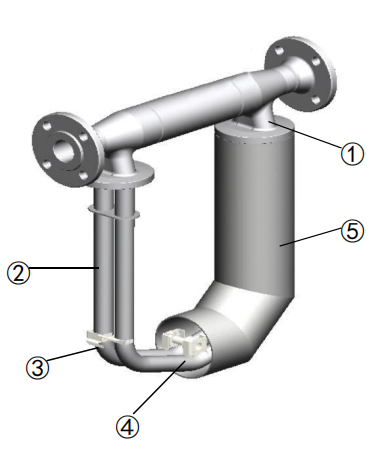

Key components include:

- Support structure: The measuring tube is fixed to the support structure and serves as the vibration axis of the vibration system.

- Measuring tube (vibrating tube): It consists of two parallel curved tubes.

- Position detector: It is used to detect the twisting change of the measuring tube.

- Drive device: It generates electromagnetic force to drive the measuring tube to vibrate at a frequency close to the resonant frequency.

- Housing: It protects the measuring tube and the drive and detection device.

- Transmitter: Converts sensor signals into mass flow, density, and temperature readings.

Featured Coriolis Mass Flow Meters

Benefits of Using a Coriolis Flow Meter

A. Universal Fluid Compatibility

Micromotion flow meters can be used with virtually any liquid or gas, regardless of conductivity, viscosity, or phase.

B. Improved Process Control

It can directly measure the mass flow, temperature, and density of the fluid. This is of great significance to the measurement of energy and the detection and control of production processes such as chemical reactions.

C. Lower Total Cost of Possession

The high reliability and low maintenance needs of these meters reduce downtime and repair costs over time.

D. Intrinsic Safety Options

Suitable for use in hazardous locations, many models are certified to meet global safety standards including ATEX, CSA, and IECEx.

E. High measurement accuracy

The measurement accuracy can be guaranteed to be between 0.1% and 0.5%.

F. Low installation requirements

The installation requirements are not high, and there are no requirements for the upstream and downstream straight pipe sections. Reliable operation and low maintenance rate.

More Flow Measurement Solutions

- What is Strain Gauge Pressure Transmitter?

- Powder/Dry Material Level Switches – Product List and Selection

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- Flow Meter Selection Guide: Starting from Measurement Conditions

- 4 Types of Manifolds for Pressure Transmitters

- Industrial Water Pressure Measurement and Monitoring

- Choose Digital Water Pressure Switch for Better Control

- What Is Temperature Compensation in a Pressure Transmitter?

- Case Study – Mass Flow Meter For Slurry

Whether you are measuring high-value chemicals in a batch process or monitoring crude oil flow on a platform, these Coriolis mass flow meters provide real-time, reliable data.

Micro motion mass flow meters measure mass flow directly and offer multivariable outputs and rugged design. Sino-Inst’s Coriolis mass flow meters are also premium flow measurement solutions that reduce complexity and increase accuracy. Our superior flow measurement solutions are popular in the market.

If you need mass flow/density measurement, please feel free to contact our Sino-Inst sales engineers!

-1.jpg)