Accurate liquid level detection is crucial for product quality and operational safety. Therefore, liquid level switches are essential components in industrial processes. They monitor and control liquid levels in tanks and containers.

Level switches are widely used in industrial environments such as chemical and food production. Sino-Inst offers high-quality level switches and solutions. These includes float, capacitive, and radar-based types.

What Is a Liquid Level Switch?

Liquid level switch, also known as liquid level sensor or liquid level detector. It is an on/off device. It provides only point-type liquid level detection. It detects the presence of liquid at a specific locati0n.It can function as a measuring device, a level monitor, or an alarm. It is suitable for a variety of products and industrial applications.

Level switches can function as measuring devices, level monitors, or alarms. They are suitable for a variety of products and industrial applications. There are many different types of level switches. The most common types include float, radar, and ultrasonic switches.

Understanding the Functions of Liquid Level Switches

Liquid level switches are essential instruments in industrial applications, including water treatment processes and industrial water supply systems. They can be used as measuring devices, level monitors, or alarms. For example, in process automation, they can signal the start or stop of pumps and valves. Depending on their design, liquid level switches have mechanical or electrical outputs. And they can be configured as normally open or normally closed systems.

For level measurement and process control, level switches are often integrated into industrial process control valves or pumps. This improves the operational efficiency and safety of the level switch.

How Does a Liquid Level Switch Work?

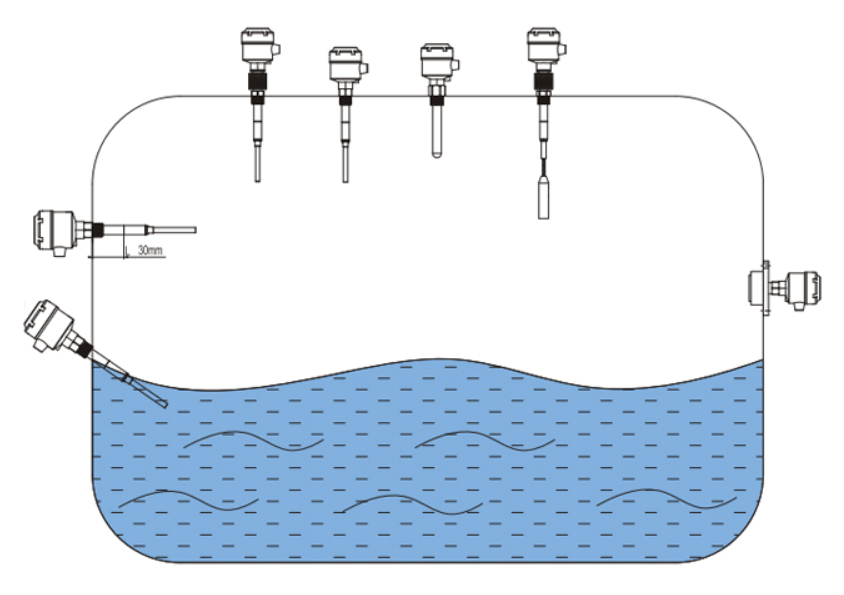

Liquid level switches detect liquid levels by using floats, conductive probes, or capacitive sensors. When the liquid level changes, a mechanical float moves up and down, triggering the switch. Electronic sensors detect changes in capacitance, conductivity, or vibration.

Common Industrial Liquid Level Switches

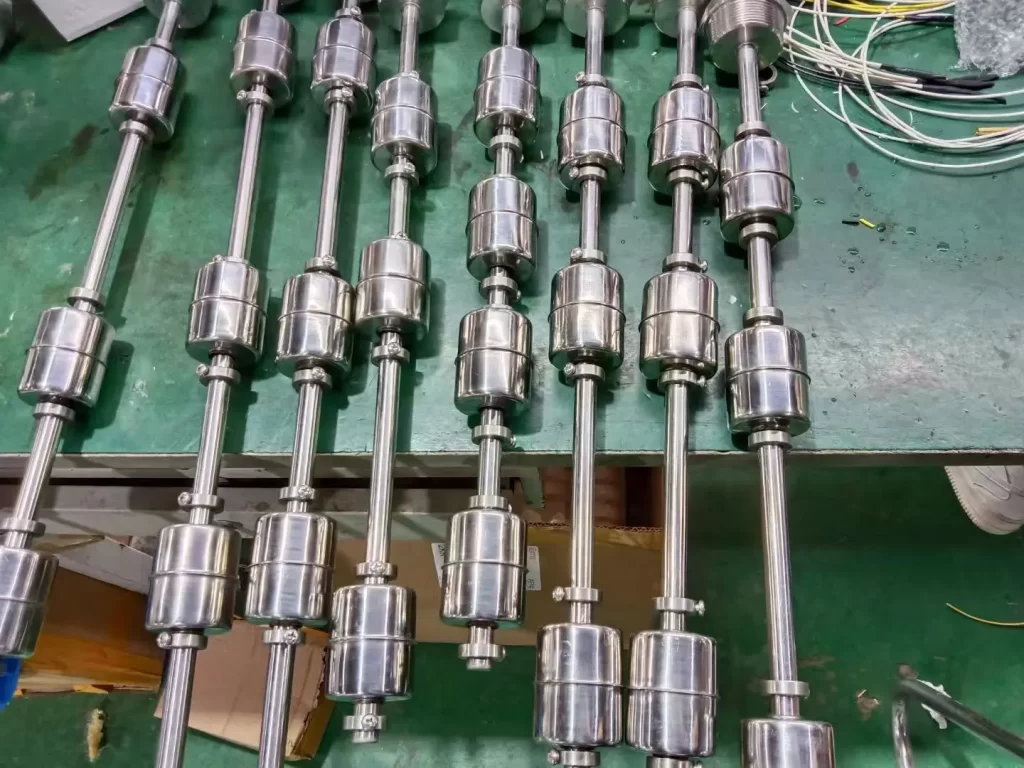

Float Level Switch

A float level switch is a simple, easy-to-use, safe, and reliable liquid level controller. It detects single or multiple extreme liquid levels, outputs a switch signal, and performs level control.

The core components of a float level switch include a magnetic float, a non-magnetic tube, and a reed switch. The float rises and falls with the liquid level. The movement of the float is mechanically linked to the switch, which opens or closes the circuit.

Float level switches are easy to install and maintain. They are designed for level detection in small and medium-sized atmospheric and pressurized liquid storage tanks. They are suitable for hazardous locations with sanitary, toxic, and corrosive media.

Read more about: Single Point – Multi-Point Float Level Switches | Simple but Effective

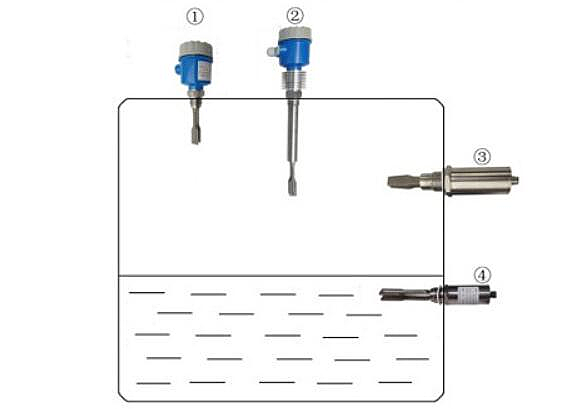

Capacitive Level Switches

Capacitive level switches measure changes in capacitance between a probe and the liquid. Liquids have a different dielectric constant than air. Because the liquid affects the capacitance between the electrode and the container, this change is converted into a signal to control the process.

When the probe is immersed in liquid, the capacitance changes dramatically, which the level switch detects. When the liquid is absent, the capacitance also changes, but the switch does not activate.

Capacitive level switches use non-contact measurement and are easy to install and maintain. They are suitable for both conductive and non-conductive liquids without a connection point. However, they cost more than basic float switches. And sometimes require calibration for optimal performance.

Ultrasonic Level Switch

Ultrasonic level switches use ultrasonic waves to detect the presence of liquid. They employ non-contact measurement and can only be mounted outside the tank. It is mainly used to detect the liquid level of the storage tank and realize upper and lower limit alarms, display the storage tank temperature (Hig-Pro type) or monitor whether there is liquid in the pipeline.

Ultrasonic level switches are unaffected by factors such as medium density, dielectric constant, and conductivity. They are suitable for level control in the pharmaceutical, petroleum, and chemical industries. They are ideal for monitoring hazardous liquids such as toxic and highly corrosive liquids.

Ultrasonic level switches provide continuous level measurement. For high-precision applications requiring non-contact or point level measurement. But ultrasonic switches are not suitable for viscous liquids, which can block ultrasonic signals. Typically cost higher than mechanical switches.

Radar Level Control Switch

A radar level control switch is a non-contact sensor. It uses radar technology to detect the liquid level of a substance.

A radar level control switch does not physically contact the material being measured. It is suitable for corrosive or viscous materials. Radar level control switches offer high accuracy. They maintain excellent performance even under harsh conditions such as temperature fluctuations, steam, or dust. They can be used for both point level switching and continuous level measurement in a variety of industries.

Tuning Fork Level Switch

Tuning fork level switch, also known as vibrating fork sensor. A tuning fork level switch uses a vibrating tuning fork to detect the level of liquid or solids in a tank. It consists of two tuning forks. These forks vibrate in air at a fixed resonant frequency.

Tuning fork level switches are simple to design and require virtually no maintenance after installation. They can operate in harsh environments such as high temperatures and high pressures. They can be used with both liquids and solids, particularly powders and granular materials. They also play an important role in overflow prevention, dry-run protection, and pump control.

Float Switch vs. Ultrasonic Level Switch

As mentioned above, float switches use a magnetic actuation principle to detect liquid level. Ultrasonic level switches transmit ultrasonic waves and receive echo signals from the liquid surface for measurement.

For cost-effective, reliable, and easy-to-use applications, choose a float switch. For non-contact, multifunctional applications, choose an ultrasonic level switch. Even in the presence of potential problems such as foam, steam, and dust, there’s no need for contact with the liquid.

| Type | Pros | Cons | Application Scenarios | Maintenance and Cost |

| Float Switch | Simple operation and installation.Works in harsh environments.Unaffected by liquid conductivity, pressure, or temperature. | Requires physical contact with the liquid.Requires regular maintenance.Limited accuracy. | Basic and cost-effective applications.Corrosive media, high temperature and high pressure environments (up to 250°C/2.5MPa). | The float switch has no electronic components. Low maintenance.Lifespan up to 2 million cycles. |

| Ultrasonic Level Switch | Non-contact measurement.High accuracy. Some models offer accuracies of 0.1% to 0.2%. Suitable for use in harsh industrial environments. | Performance is affected by environmental factors. Proper calibration is required. Pricier than a float switch. | Industrial, continuous, or high-precision monitoringApplicable to both non-conductive and conductive liquids.Applicable to corrosive or viscous liquids. | Ultrasonic switches are relatively expensive. They require regular maintenance and calibration. |

Differences Between Liquid Level Sensors and Liquid Level Switches

| Type | Liquid level switches | Liquid level sensors |

| Function | Detects a single, specific liquid level in a container. | Continuously measures the level of fluids in containers. |

| Output | Provides an on/off (binary) signal. | Provides a continuous analog signal proportional to the liquid level. |

| Measurement Method | Point level measurement. | Continuous level measurement. |

| Application | Used for simple point detection. | Monitors the level of liquids in storage tanks. Controls processes requiring precise level measurement. |

| Advantages | Easy to install and operate.Generally low cost. Some types, such as float switches, do not require power. | Provides accurate, continuous measurement.Can be used for complex processes and precise inventory management. |

Applications of Liquid Level Switches

- Point level detection. Point level detection switches activate when a specific liquid level is reached. They also prevent overflow and dry running.

- Non-contact level control. Non-contact level switches utilize technologies such as ultrasonic and radar. They offer non-contact measurement solutions.

- Pump control. Level switches automatically turn pumps on and off. For example, they can turn a pump on when the liquid level is low and off when it is full.

- Overflow prevention. Level switches are placed near the top of a tank and shut off the liquid supply when the liquid level is too high, preventing overflows.

- Water and wastewater. Used for raw water, process, and backwash tanks in water treatment plants, as well as for wastewater pump control.

- Food and beverage. Used for storage tanks and process vessels in sanitary and food-grade applications.

What Are the Advantages of a Liquid Level Switch?

Versatility

Level switches can be used in a variety of applications and fluids, including viscous slurries, oils, corrosive fluids, and molten metals. Their versatility enables them to meet a wide range of monitoring needs.

Easy Installation

Level switches are very simple to install. Depending on the type of level switch, installation can be completed in one to two hours. They can also be easily relocated if the storage configuration changes. For example, with a float switch, simply connect the wires and place the float in the liquid.

Reliability and Durability

Many types of level switches, such as float or reed switches, feature a simple design. With few moving parts, level switches provide reliable performance and accurate data. This makes them highly reliable and durable, capable of operating millions of times.

Low Maintenance

With minimal moving parts, level switches require virtually no maintenance. Routine calibration is all that’s needed to maintain accuracy, and the likelihood of failure is very low. Their durable and rugged construction makes them an excellent choice for low-cost, high-performance level control solutions.

How Do I Choose the Right Liquid Level Switch?

When selecting a level switch, you must consider several factors. These include the tank type, wiring type, switch location, and the nature of the liquid being measured.

Vessel Size

Level switches are compact and easy to operate. However, some types of switches are easier to fit into certain container sizes. This may seem simple, but it’s often overlooked. The first step in selecting a level switch is to measure the container size and determine the number of switches required.

Liquid Properties and Switch Material

Level switches are made from a variety of materials. When deciding which level switch to purchase, it’s important to ensure that the switch material is compatible with the liquid to prevent corrosion. Manufacturers typically use brass, stainless steel, and various plastics.

Mounting the Switch

When installing, consider the size of the mounting hole, whether the connection is threaded, and whether the switch will be pendant or wall-mounted. The switch must be suitable for the size and shape of the tank, as well as its open or closed state.

Temperature and Pressure

Different level switches have varying temperature tolerances. For high-temperature or high-pressure environments, switches made of materials such as stainless steel and with higher temperature ratings are required.

Liquids exert pressure due to their weight. Therefore, when selecting a level switch, be sure to evaluate whether the measured liquid will exert pressure on the switch. In such cases, consider a level switch made of a material capable of withstanding high pressure.

Switch Technology

When selecting a level switch, consider the switch technology. Different technologies are suitable for different applications. For example, float switches are suitable for turbulent and dirty fluids. Ultrasonic switches are suitable for liquids, powders, and granules. Capacitive switches are suitable for a variety of aqueous and hydrocarbon media.

Switch Output

Different level switches offer various output types, such as relays, analog, or digital signals. The output type must be compatible with the controller receiving the data. Furthermore, time delays may need to be considered when selecting the output.

More Level Measurement Solutions

Liquid level switches are a cost-effective way to monitor, control, and regulate liquid levels. While seemingly small, they are a vital component of production operations. They are crucial for controlling and regulating the levels of bulk materials or liquids. Their accuracy, durability, and versatility improve system efficiency and safety.

Sino-inst manufactures and supplies a wide range of liquid level switches, float switches, and level sensors. We also offer level controllers. Such as tuning fork level switches and rotary paddle level switches. To purchase a liquid level switch or request product information, please contact us today to begin your shopping journey.

-1.jpg)