In the production process of modern industry, bulk flow meters for solids is increasingly widely used, and its performance requirements are getting higher and higher.

In order to solve the problem of replacing equipment such as scales in the industry of powder material processing, manufacturing or handling, our company has developed a Bulk Flow Meter, a precision device for measuring and controlling the flow of powder materials.

Main advantages of Bulk Flow Meter:

Bulk Flow Meter is a meter specially used to measure the flow of solid materials. Its working principle is based on the physical characteristics of materials during the flow process. Its core part is usually a sensor. When solid materials pass through the sensor, the sensor will detect the flow of materials and convert it into an electrical signal output, thereby realizing the measurement of solid flow.

Advantages: Compared with traditional liquid flow meters, Bulk Flow Meter has the following advantages:

- High accuracy: The solid flow meter adopts advanced sensing technology and data processing methods to achieve high-precision flow measurement.

- Strong adaptability: Whether it is granular or powdery, as long as it is within the range of 0.01uM~2000uM, the solid flow meter can perform accurate measurement.

- Good stability: In harsh industrial environments, the solid flow meter can still maintain stable performance and ensure the accuracy of measurement.

- Easy maintenance: The solid flow meter has a reasonable structural design and simple maintenance, which reduces the user’s maintenance cost.

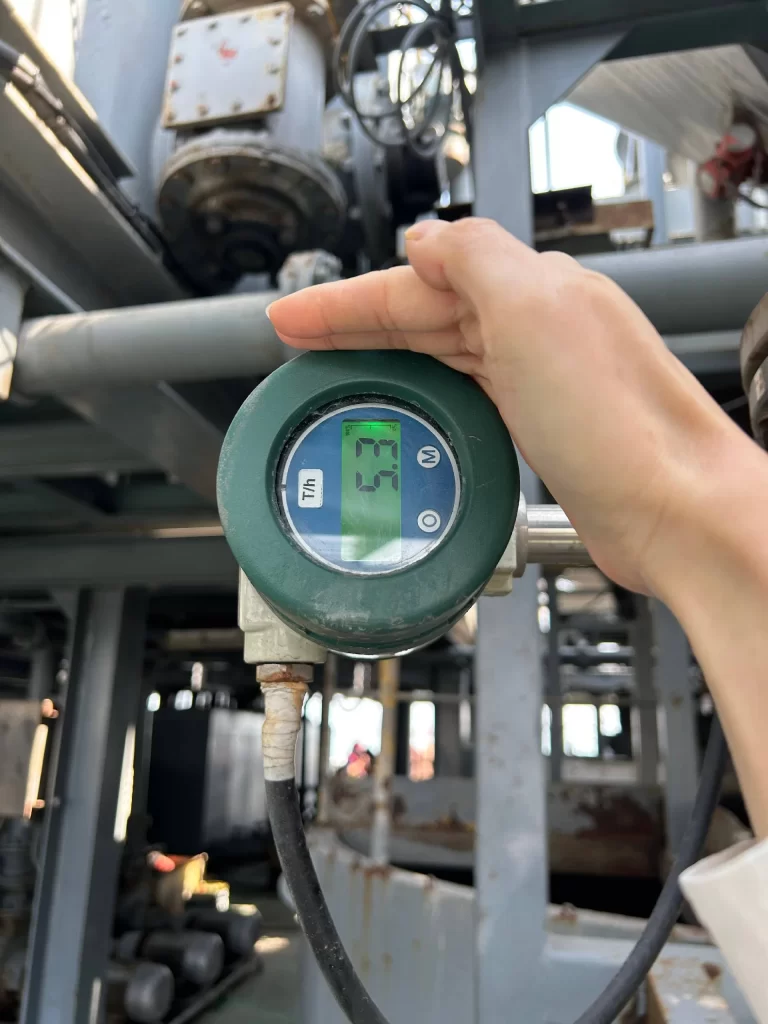

Bulk Solids Measurement Case

Measurement background

- The powder flow meter uses a stainless steel pipe with a size of DN300mm

- A flow integration system is required. The flow integration system is an important part of the flow meter, which can process and calculate the flow data and output the results to the control system.

- Control the opening degree of the valve. It can ensure the flow speed and stability of the material in the pipeline and ensure the accuracy of the production process.

- Switch output. The switch output of the powder flow meter is one of the important functions. When the material flow reaches the set value, the switch output will send a signal. The control system can perform corresponding operations according to the signal

According to the customer’s on-site needs, the powder flow meter needs a flow integration system, can control the valve, and has switch output and other functions.

Measurement tasks

- Detect powder flow and data storage

- Calculate daily tonnage

- All data should be stored for at least 6 months

Solution

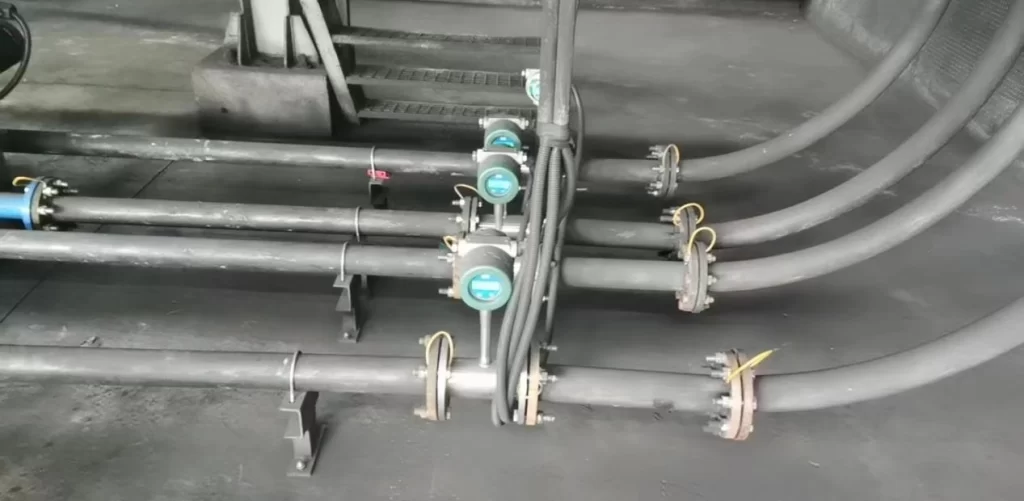

- Use two DN300 flowmeters to detect on-site flow data;

- The totalizing system calculates the daily kilograms/tons; output quantity;

- Switch output, control the powder flow delivery through the valve;

- Data is stored in the flow totalizing system;

Measurement advantages

- Standard two-wire transmitter, 24V loop power supply, 4-20mA current signal output, aluminum alloy shell is waterproof.

- Easy to operate. Open the sealing cover to see the wiring terminals. The signal cable passes through the threading hole on the transmitter housing and is fixed to the terminal (the wiring is not positive or negative). Screw the locking screw of the threading hole to the appropriate position to prevent water from entering, and finally cover the sealing cover.

- High measurement accuracy;

- High system reliability;

- Easy installation within one day, including on-site calibration.

More Flow Measurement Solutions

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

- Metal Tube Rotameter: Working Principle and Applications

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

Bulk Flow Meter can improve the process, increase operational efficiency, and help you save costs significantly. Display material flow in the process, detect solid material inventory, truck, ship, train solid material loading, quantitative material quality control, and production monitoring.

Sino-Inst supports customized Bulk Flow Meters. It is used for the flow of powdered and granular materials. If you need to purchase or have related technical questions, please feel free to contact us.

-1.jpg)