What is a Torque Coupling?

A torque coupling is a component that connects the driving machine to the driven machine. Its main functions are overload protection and compensation. When an overload or mechanical failure causes the required torque to exceed the set value, it limits the torque transmitted by the transmission system through slippage. It automatically restores the connection after the overload condition disappears.

Torque couplings are also known as torque limiters, safety couplings, or safety clutches.

Functions of Torque Couplings

Essentially, torque transmission involves transferring rotational power from a driver (such as an electric motor) to a driven shaft (such as a pump or compressor) while maintaining efficiency. Torque-limiting couplings have two main functions: torque protection and compensation.

Overload Protection:

Torque couplings are energy-efficient, have high transmission efficiency, are safe and reliable, easy to install and adjust, and easy to maintain. They can withstand peak impacts, and in case of torque overload, the coupling slips, protecting the machinery from damage during overload operation and preventing equipment damage and downtime losses.

Misalignment Compensation:

A good coupling can accommodate three unavoidable types of misalignment without causing shaft breakage or bearing damage.

- Radial misalignment: The two shafts are parallel but not on the same centerline.

- Angular misalignment: The two shafts intersect at an angle, rather than being in a straight line.

- Axial misalignment: The distance between the two shafts changes (usually due to thermal expansion).

Main Types of Torque Couplings

When we look at power transmission components, one size definitely does not fit all. Choosing the wrong type is the fastest way to destroy a bearing or snap a shaft. Generally, we categorize these into three buckets: Rigid, Flexible, and Safety types.

Rigid Couplings: When Alignment is Perfect

If you have two shafts that are perfectly aligned and won’t move, rigid couplings are your best bet. They provide a solid, locked connection.

- Types: Flanged, sleeve, and clamp styles.

- Pros: High torque capacity, zero backlash, and low cost.

- The Catch: They have zero misalignment tolerance. If the shafts shift even slightly, that stress goes straight into your motor bearings.

Flexible Shaft Couplings: Compensating for Errors

In the real world, shafts are rarely perfect. That’s why flexible shaft couplings are the industry standard. They offer shaft misalignment compensation while still transmitting power efficiently.

- Elastomeric Couplings (Jaw types): These use a rubber or urethane element (spider). They are torsionally flexible couplings, meaning they dampen vibration well. The elastomeric coupling insert takes the beating so your metal parts don’t have to.

- Metallic Couplings (Disc and Bellows): When you need precision. A disc coupling uses thin metal shims to flex. They are typically a backlash-free coupling solution, making them ideal for robotics and servo applications where positioning accuracy is key.

- Gear and Grid Couplings: These are the workhorses. A grid coupling or gear type provides high torque density coupling capabilities. They are built for heavy loads in mining or steel mills but usually require grease lubrication.

Torque-Limiting Couplings

Think of these as a circuit breaker for your mechanical system. An overload protection coupling will mechanically disengage if the torque spikes too high (like if a conveyor jams), saving your expensive motor or gearbox from catastrophic failure.

Torque Coupling Selection Guide

Selecting the right power transmission components isn’t just about matching shaft sizes; it’s about ensuring your entire system runs without downtime. When I help clients navigate a coupling selection guide, I treat it like a logic puzzle where every piece—torque, speed, and environment—must fit perfectly.

Here is the step-by-step process I use to zero in on the perfect torque coupling:

- Assess System Requirements

What is the continuous torque, and more importantly, what is the peak startup torque?

Power & Speed: Determine the driver (motor) and driven (pump, gearbox) equipment HP/kW and RPM.

Misalignment: Be realistic. Measure or estimate the expected angular, parallel, and axial offsets. If the system has significant movement, you need a unit with high misalignment tolerance.

- Calculate Service Factors

Never size a coupling based solely on nominal torque. I always apply a service factor to handle shock loads, vibrations, and temperature shifts.

- Uniform loads (fans, blowers) might only need a 1.0–1.2 factor.

- Heavy shock loads (crushers, reciprocating pumps) often require a factor of 2.0 or higher.

- Multiplying your nominal torque by this factor gives you the “Design Torque,” ensuring you don’t shear an elastomeric coupling insert the first time you hit the start button.

- Shortlist Suitable Types

Now, match the requirements to the coupling style.

- High Misalignment: If the shafts aren’t perfectly aligned, I look at a jaw coupling or universal joint.

- High Precision: For motion control where timing is everything, I stick to a backlash-free coupling or a disc coupling.

- Vibration Damping: If the machine rattles, you need a flexible shaft coupling that absorbs shock.

- Verify Dimensions and Mounting

A coupling that can handle the load is useless if it doesn’t fit. I double-check:

- Bore Sizes: Shaft diameters and keyway dimensions.

- Space Limitations: The Distance Between Shaft Ends (DBSE) and the maximum outer diameter allowed.

- Mounting: Clamp style, set screw, or flanged? This affects installation speed and hold.

- Consider Supplier Support

Finally, we recommend considering the logistics. Does the supplier have stock for quick replacements? In my experience, a slightly more expensive industrial shaft coupler that is readily available is worth far more than a cheap one with a 12-week lead time.

More Torque Measurement Solutions

Torque Wrench Calibration Guide | DIY and ISO Standards

Strain Gauge Torque Sensors & Transducers – Technology and Selection Guide

What is a Reaction Torque Sensor? Product Lists and Guide

Static Torque vs Dynamic Torque: A Practical Guide to Selecting the Right Sensor in 2026

Motor Torque Measurement – Static and Dynamic Sensors

What Is a Torque Sensor? and Types

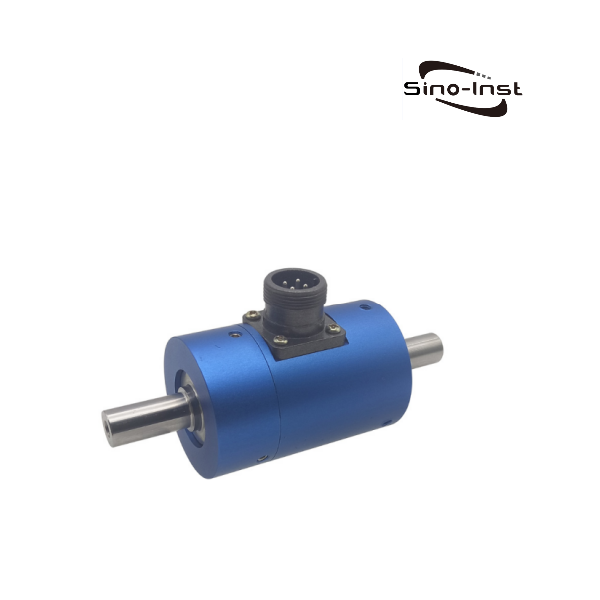

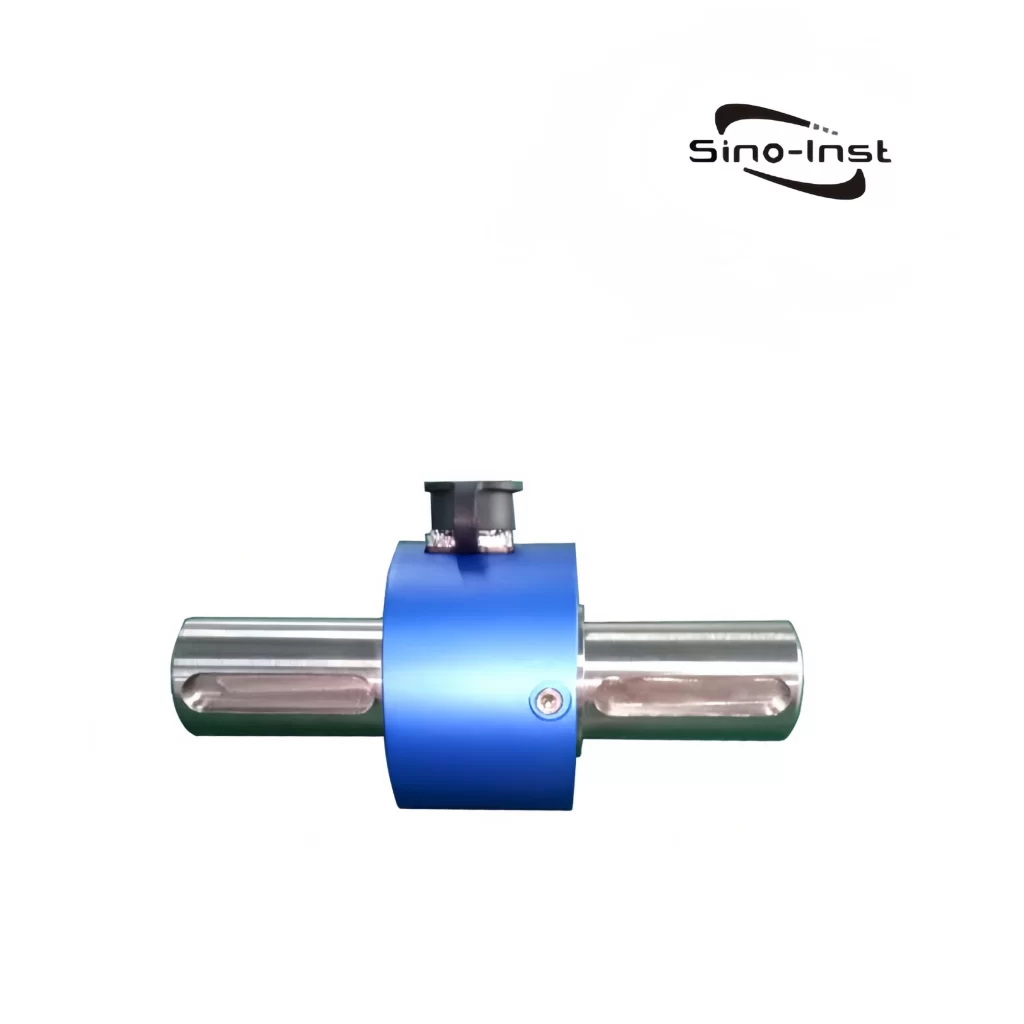

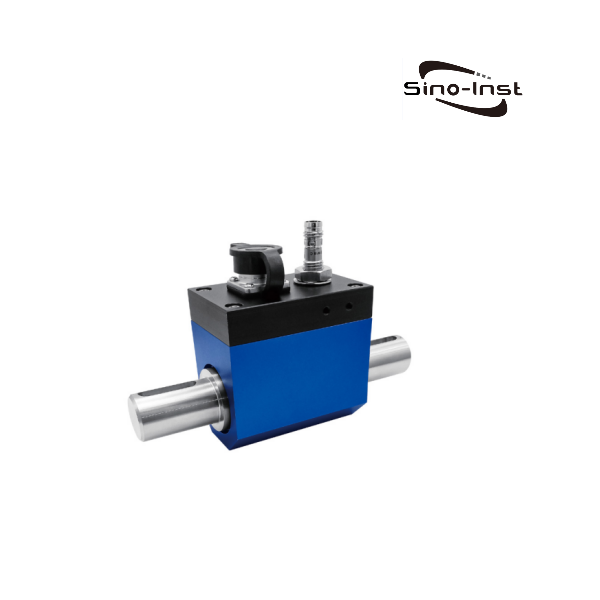

The coupling paired with the torque sensor is a crucial component for accurate torque measurement. When using the torque sensor, it must be installed between the power source and the load, connected by two couplings. The power source and load equipment must be securely fixed to prevent vibration; otherwise, the instrument will not function properly.

Sino-Inst provides various customized torque measurement services. Please feel free to contact us!

-1.jpg)