Optical liquid concentration meters calculate concentration values based on the different refractive indices of media with varying concentrations. They utilize the diffusion characteristics of light spectra in liquids, sampling through a high-resolution spectral sensor, and analyzing the data using software to determine the concentration patterns. Temperature compensation is then applied to measure the concentration of various liquids or liquid mixtures.

This is one of the most commonly used liquid density technologies in laboratory and industrial settings.

Features

Technical Specifications

| Accuracy | ±0.5% |

| Operating Range | 0~100% (20℃), calibrated to a specific range depending on usage |

| Repeatability | ±0.2% |

| Process Temperature Influence (Corrected) | ±0.001% (per℃) |

| Process Pressure Influence (Corrected) | Negligible |

| Process Temperature | –10℃~+60℃ |

| Ambient Temperature | –10℃~+45℃ |

| Temperature Coefficient | 0.1%/m³/℃ (after calibration) |

| Built-in Temperature Sensor | Temperature chip |

| Wetted Parts Material | 316L, PTFE |

| Glass | Acid and alkali resistant |

| House Material | IP65, aluminum alloy |

| Maximum Operating Pressure | 0.8MPa |

| Test Pressure | Tested at 1.5 times the maximum working pressure |

| The actual maximum working pressure is limited by the process connection rating. | |

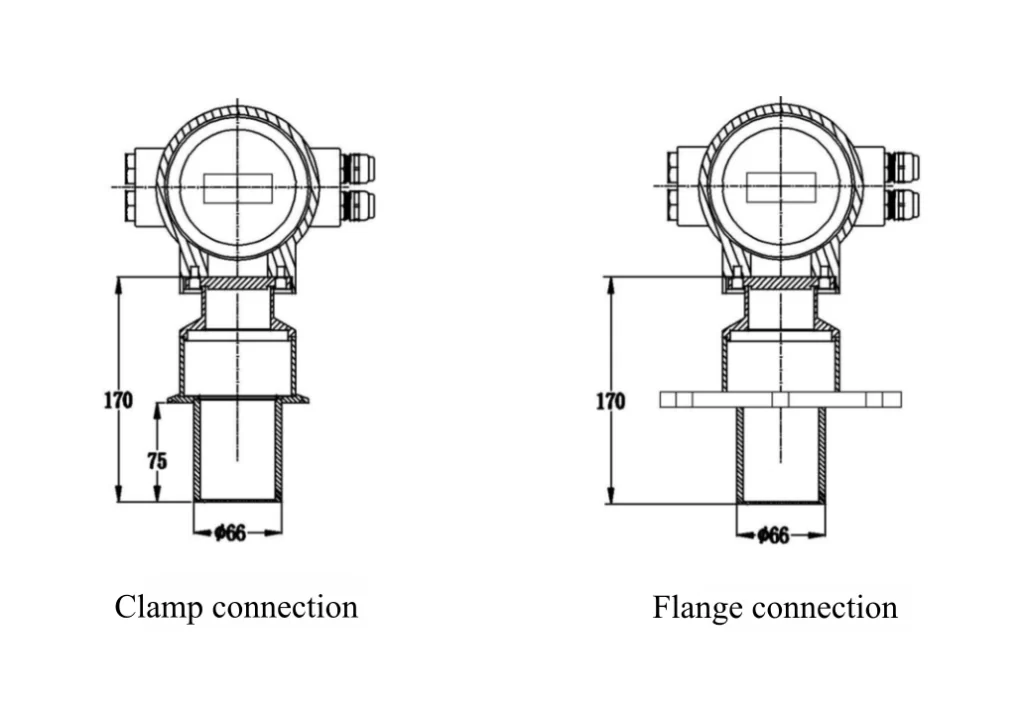

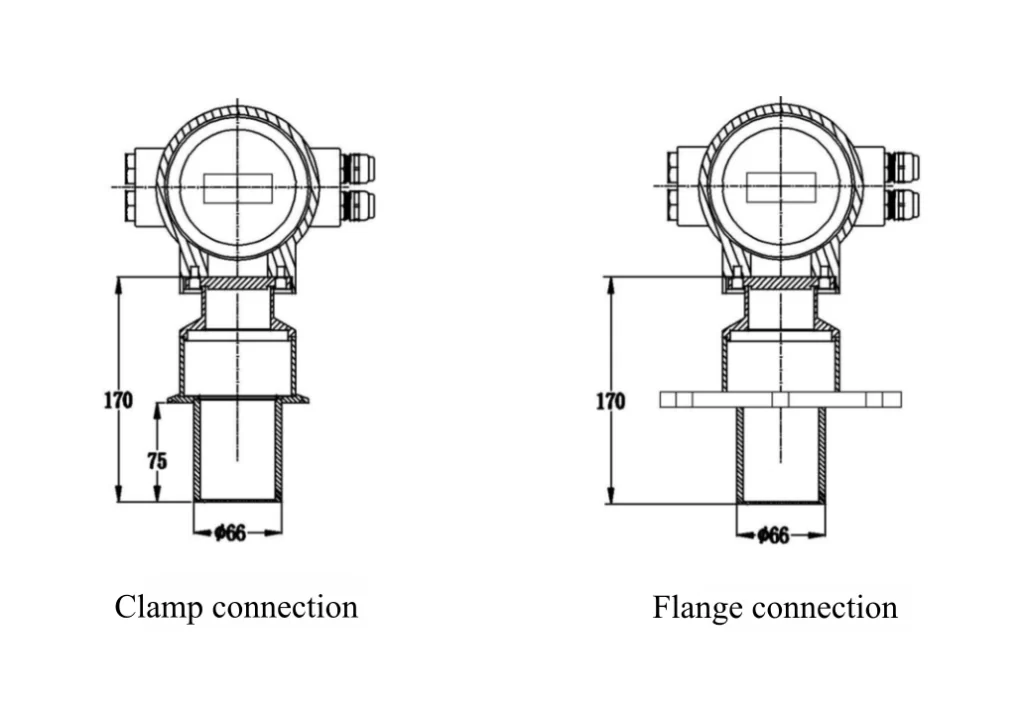

| Process connection type | Flange |

| Clamp | |

| Explosion-proof certification | Ex d ⅡC T6 Gb |

| Power requirements | 24 VDC, 50mA |

| Output | Four-wire system, 4-20mA |

| Viscosity range | <5000MPa.s |

Liquid and material compatibility:

| Type | Name | Molecular formula | concentration(%) | 316L | Hastelloy | titanium alloy | zirconium | PTFE |

| Acids | Hydrochloric acid (excluding hydrofluoric acid) | HCI | 0-40 | × | ○ | × | ☆ | ☆ |

| Sulfuric acid | H2SO4 | 0-50 | ○ | ☆ | ○ | ☆ | ☆ | |

| H2SO4 | 50-75 | × | ○ | × | ○ | ☆ | ||

| H2SO4 | 75-98 | ○ | ☆ | ○ | ○ | ☆ | ||

| Nitric acid | HNO3 | 0-100 | ○ | ○ | ○ | ○ | ☆ | |

| Phosphoric acid | H3PO4 | 0-98 | × | × | × | × | ☆ | |

| Bases | Sodium hydroxide | NaOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ |

| Potassium hydroxide | KOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Calcium hydroxide | Ca(OH)2 | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Salts | Sodium chloride | NaCl | 0-50 | × | ☆ | ☆ | ☆ | ☆ |

| Ammonium chloride | NH4Cl | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Ammonium sulfate | (NH4)2SO4 | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Others | Urea | (NH2)2CO | 0-100 | ☆ | ☆ | ○ | ☆ | ☆ |

| Sodium hypochlorite | NaOCI | 0-16 | × | ○ | × | ☆ | ☆ | |

| Hydrogen peroxide | H2O2 | 0-90 | ☆ | ☆ | ○ | ☆ | ☆ | |

| ☆Recommended ○Use under specific concentration and temperature limits ×Do not use | ||||||||

Liquid Concentration Meter – Optical Working Principle

Optical concentration meters utilize the diffusion patterns of spectra in liquids. High-resolution spectral sensors sample the light, and software analyzes and processes the data to determine concentration patterns. Temperature compensation is then applied to measure the concentration of various liquids or liquid mixtures.

An optical concentration meter consists of a transmitter and a sensor. The sensor can be easily installed in pools, drains, pressure pipelines, or natural water bodies. It automatically compensates for interference caused by contamination. The sensor has an air-cleaning function that automatically cleans itself at preset times, reducing maintenance workload.

The light emitted from the transmitter on the sensor is absorbed, reflected, and scattered by the analyte during transmission, with only a small portion reaching the detector. The transmittance of the transmitted light is related to the concentration of the wastewater being measured; therefore, measuring the transmittance allows calculation of the wastewater concentration.

Four-beam technology uses two detectors and two transmitters. The light emitted from the transmitter is transmitted and reaches the two detectors. This series of optical paths forms a data matrix. Analyzing these data signals reveals the concentration of suspended solids in the medium. It also effectively avoids interference and compensates for deviations caused by contamination. The instrument can operate even in harsh environments.

| Media restrictions | Bubbles, Flow Velocity | Maximum Liquid Viscosity | |

| Particles | Transparent | ||

| Trace particles | Transparent, pure liquid | Minimal bubbles | 5000MPa.s |

| Flow velocity > 1.5 m/s | |||

Featured Applications

More Densitometers and Density Measurement Solutions

What Is a Density Meter? And Guide to Types

Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

Online optical concentration meters are specifically designed for measuring the concentration—density— of liquids. They are commonly used to measure the concentration of chemical liquids such as ammonia, urea, cleaning agents, ethylene glycol, and acid/alkali solutions.

We at Sino-Inst supply various types of concentration meters and densitometers, and support customized measurement parameters. Please feel free to contact our sales engineers!

Liquid Concentration Meter - Optical Principle - Sino-Inst

Optical liquid concentration meters calculate concentration values based on the different refractive indices of media with varying concentrations. They utilize the diffusion characteristics of light spectra in liquids, sampling through a high-resolution spectral sensor, and analyzing the data using software to determine the concentration patterns. Temperature compensation is then applied to measure the concentration of various liquids or liquid mixtures.

Product SKU: Liquid Concentration Meter - Optical Principle

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)