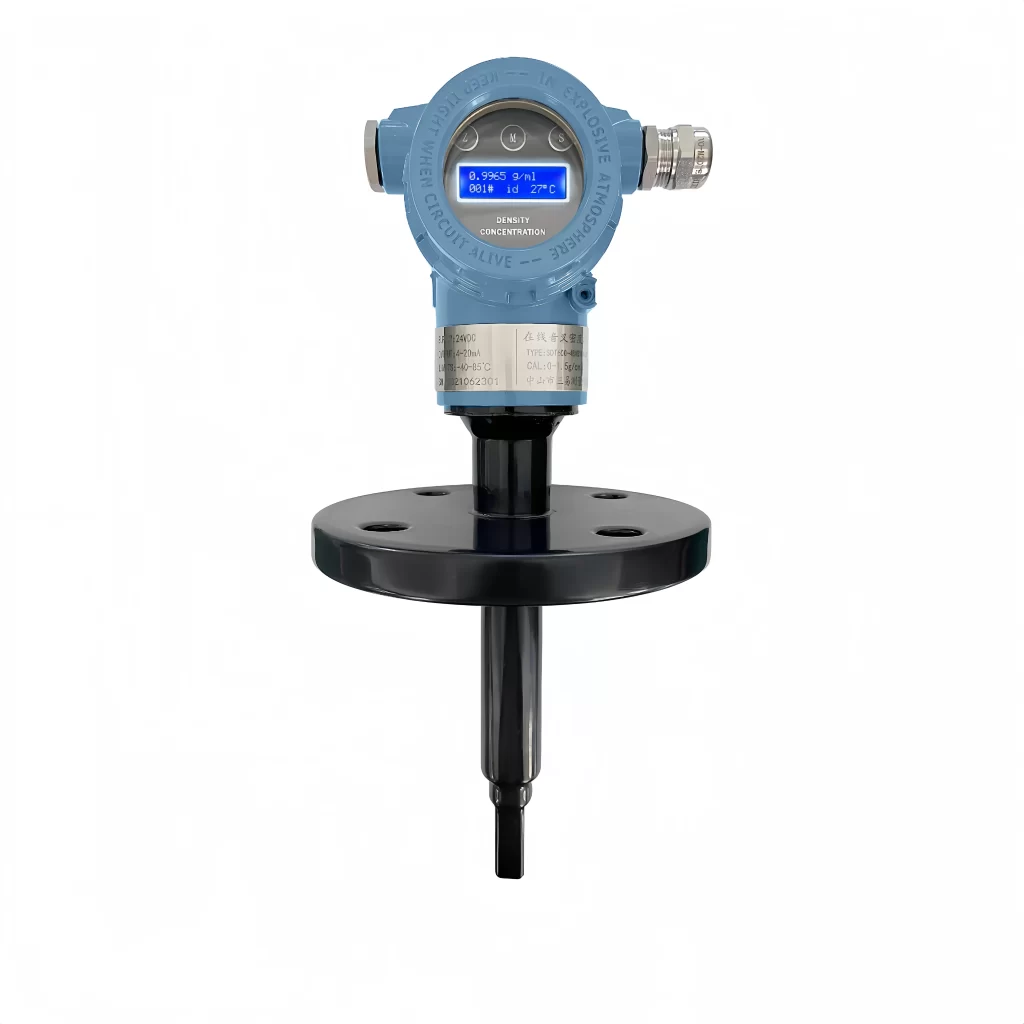

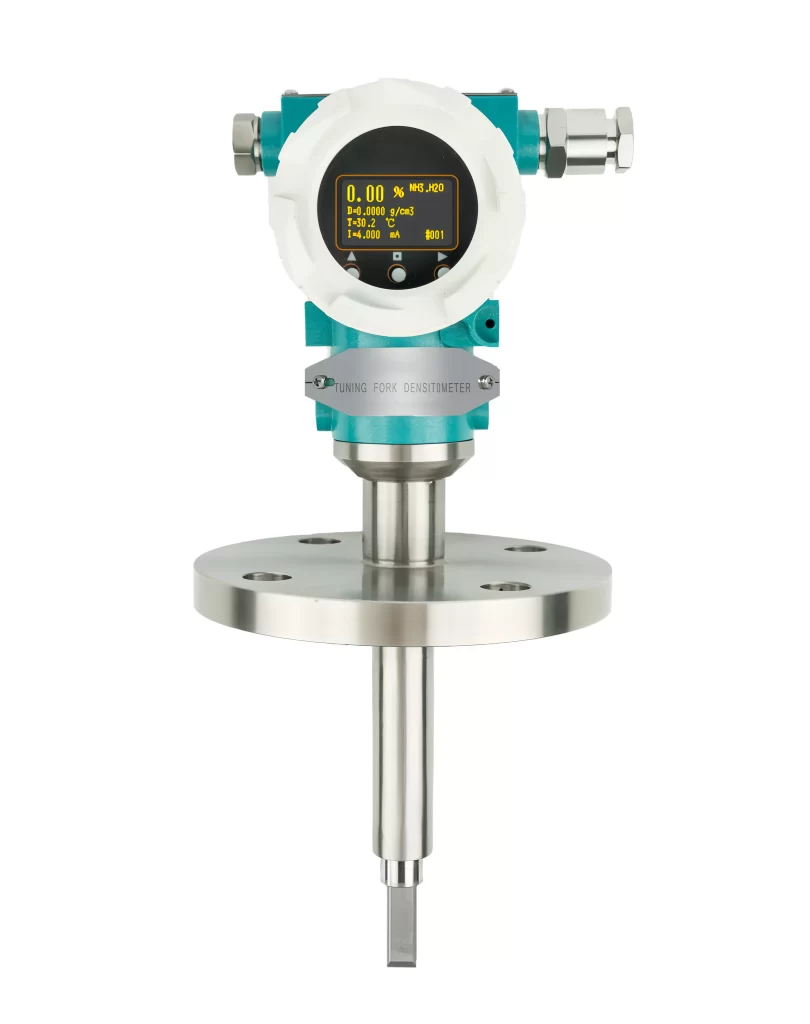

The online Tuning Fork Density Meter is used to measure the concentration of liquid media in tanks and pipelines. Concentration measurement is an important process control in product manufacturing. The Tuning Fork Density Meter can also be used as an indicator of other quality control parameters such as solid content or concentration. It can meet various user requirements for measuring density, concentration, and solid content.

Sino-Inst supplies Tuning Fork Density Meters made of special materials such as 316L, titanium, zirconium, ceramic, 2507 stainless steel, Hastelloy C, and PTFE/PFA.

Features

Technical Parameters

| Accuracy (Standard Conditions) | ±0.001g/cm³ | ±0.5(v/v,m/m) |

| Operating Range | 0~2g/cm³ | 0~100% |

| Repeatability | ±0.0001g/cm³ | ±0.1% |

| Process Temperature Effect (Compensated) | ±0.0001g/cm³ | ±0.1% (per °C) |

| Process Pressure Effect (Compensated) | Negligible | Negligible |

(1) The above accuracy applies to the calibration range of 0.8–1.5 g/cm³ (800–1500 kg/m³).

(2) Liquid viscosity may reach up to 2000 cP (subject to specific medium characteristics).

(3) Temperature effect refers to the maximum measurement deviation caused by process fluid temperature deviation from factory calibration temperature.

(4) Pressure effect is defined as the change in sensor flow and density sensitivity due to process pressure deviation from calibration pressure.

| Temperature Specifications | ||

| Process Temperature | Standard: -25℃~+120℃ Customized: -25℃~+150℃ | |

| Ambient Temperature | -25℃~+85℃ | |

| Temperature Accuracy | 0.5℃ | |

| Built-in Temperature Sensor | Temperature Chip | |

| Structural Material | ||

| Wetted Parts | 316L, Hastelloy, Titanium Alloy, Ceramic, etc. | |

| Fork Polishing | Standard Polishing, PTFE Coating, Electrolytic Polishing | |

| Housing | IP67, Aluminum Alloy | |

| Pressure Rating | ||

| Maximum Operating Pressure | Standard | Within 0.4MPa |

| Customized | Within 2MPa | |

| Test Pressure | Tested at 1.5 times the maximum working pressure | |

| Actual maximum operating pressure is limited by process connection ratings | ||

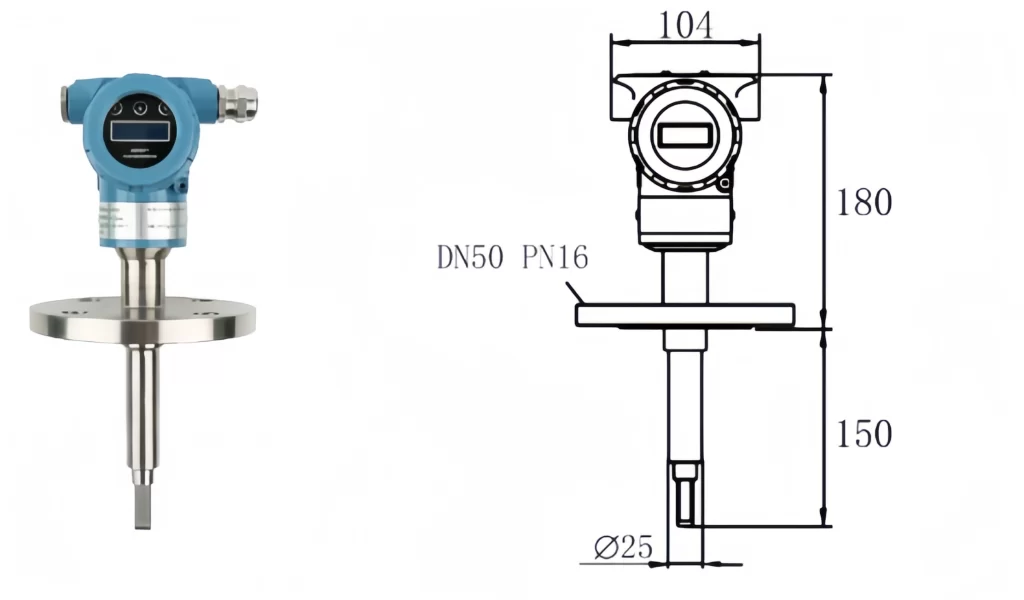

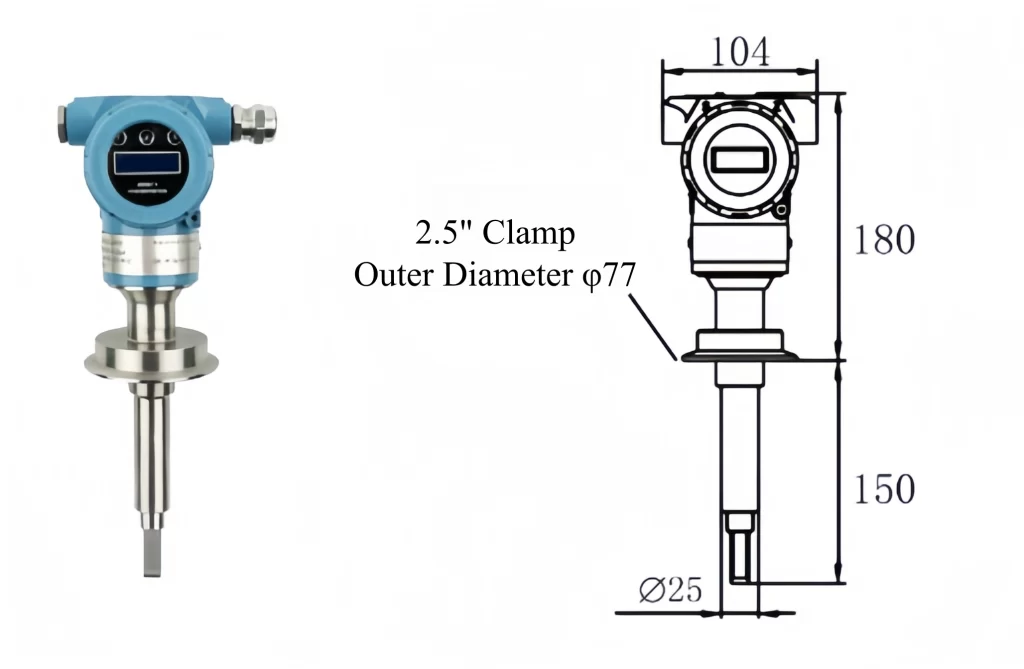

| Process Connection Type | Flanges, clamps, threads | |

| Explosion-proof Standard | Ex d IIC T6 Gb | |

| Power Requirements | 1. 24VDC, 100mA | |

| 2. 220VAC to 24VDC power converter (optional) | ||

| Output | Four-wire, 4-20mA, RS485 or HART protocol | |

| Electrical Interface | M20*1.5 | |

| Viscosity Requirements | 0-2000cP (depending on the specific characteristics of the medium) | |

Liquid and Material Compatibility

| Name | Name | Molecular Formula | Concentration (%) | 316L | Hastelloy | Titanium Alloy | Zirconium | PTFE |

| Acid | Hydrochloric acid (excluding hydrofluoric acid) | HCl | 0-40 | × | × | × | × | ☆ |

| Sulfuric acid | H2SO4 | 0-50 | × | ○ | × | ☆ | ☆ | |

| H2SO4 | 50-75 | × | × | × | ○ | ☆ | ||

| H2SO4 | 75-98 | × | × | × | × | ☆ | ||

| Nitric acid | NHO3 | 0-100 | ○ | ○ | × | × | ☆ | |

| Phosphoric acid | H3PO4 | 0-98 | × | ○ | × | × | ☆ | |

| Base | Sodium hydroxide | NaOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ |

| Potassium hydroxide | KOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Calcium hydroxide | Ca(OH)2 | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Salt | Sodium chloride | NaCl | 0-50 | × | ☆ | ☆ | ○ | ☆ |

| Ammonium chloride | NH4Cl | 0-50 | × | ☆ | ☆ | ○ | ☆ | |

| Ammonium sulfate | (NH4)2SO4 | 0-50 | × | ☆ | ☆ | ○ | ☆ | |

| Other | Urea | (NH2)2CO | 0-100 | ☆ | ☆ | ○ | ☆ | ☆ |

| Sodium hypochlorite | NaOCl | 0-16 | × | ○ | × | × | ☆ | |

| Hydrogen peroxide | H2O2 | 0-90 | ☆ | ☆ | ○ | ☆ | ☆ | |

| ☆Recommended ○Use under specific concentration and temperature limits × Do not use | ||||||||

Featured Application Industries:

- Petrochemical Industry: Diesel, gasoline, ethylene, etc.

- Chemical Industry: Sulfuric acid, hydrochloric acid, nitric acid, hydroacetic acid, ammonia, methanol, ethanol, brine, sodium hydroxide, refrigerant, sodium carbonate, glycerin, hydrogen peroxide, etc.

- Pharmaceutical Industry: Pharmaceutical solutions, biological liquids, alcohol extraction, acetone, alcohol recovery, etc.

- Food and Beverage Industry: Sugar water, fruit juice, brewing, cream, etc.

- Battery and Electrolyte Industry: Sulfuric acid, lithium hydroxide, etc.

- Environmental Protection Industry: Desulfurization (lime slurry, gypsum slurry), denitrification (ammonia, urea), wastewater treatment MVR (acid, alkali, salt recovery), etc.

| Petroleum and petrochemical industry | Interface detection; multi-product pipelines; |

| Chemical industry | Acid, alkali, and salt production; quality control; |

| Alcohol industry | Continuous online monitoring; |

| Organic and inorganic chemical materials | Underground storage tanks using brine; |

| Pharmaceutical industry | Chinese herbal medicine concentration, alcohol recovery; |

| Battery industry | Lithium hydroxide, electrolyte, sulfuric acid solution concentration; |

Working Principle of Tuning Fork Density Meter

An online tuning fork density (concentration) meter uses an acoustic frequency signal source to excite a metal tuning fork, causing it to vibrate freely at its center frequency. This frequency has a direct correlation with the density of the liquid in contact with it; therefore, the density of the liquid can be measured by analyzing the frequency. Temperature compensation can then be applied to eliminate temperature drift in the system. The concentration can be calculated at 20°C based on the relationship between the liquid’s density and concentration.

| Particle size limitation | Contains gas | Maximum liquid viscosity | |

| Particle diameter | Suspended particulate matter % | ||

| <10 micrometers | <=40% | Recommended | 500cp |

| 10~50 micrometers | <=20% | Generally not used | 2000cp |

FAQ

More Technical Support

Our Sino-Inst tuning fork densitometers offer accurate measurements at a high cost-performance ratio. They can display density, concentration, and temperature values simultaneously on the screen. An integrated temperature sensor provides temperature compensation, resulting in more accurate measurement results.

If you also need to measure the density of media in tanks, pipelines, etc., please feel free to contact us to customize a tuning fork vibrating densitometer.

Tuning Fork Density Meter/Concentration Meter - Sino-Inst

The online Tuning Fork Density Meter is used to measure the concentration of liquid media in tanks and pipelines. Concentration measurement is an important process control in product manufacturing. The Tuning Fork Density Meter can also be used as an indicator of other quality control parameters such as solid content or concentration. It can meet various user requirements for measuring density, concentration, and solid content.

Product SKU: Tuning Fork Density Meter/Concentration Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 1599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)