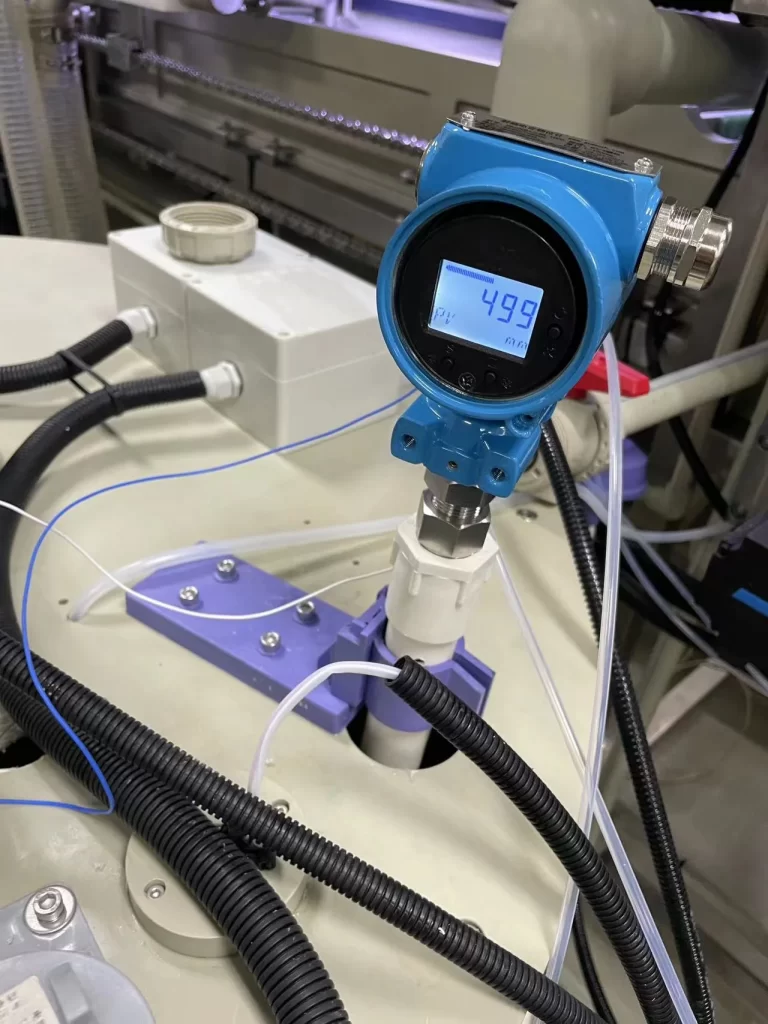

The RF admittance level switch is a level detection device based on RF admittance technology, an upgrade from capacitive level technology. It is anti-fouling, more reliable, and more accurate. It is widely used for measuring liquids, slurries, and granular materials.

It detects changes in the medium through the capacitance formed by the probe and the container wall. A new oscillator buffer and AC converter chopper driver have been added to solve the problem of sensor fouling.

Features

Technical Parameters

| Power Supply: | 24VAC±5VAC (standard); 220VAC±50VAC 50/60HZ (standard), 110VAC±25VAC 50/60HZ (optional) |

| Output: | DPDT relay (double pole double throw), 4~20mA; |

| Output Capacity: | 220VAC 5A |

| Ambient Temperature: | -40℃~70℃ |

| Medium Temperature: | -100℃~800℃ |

| Resolution: | <0.5PF |

| Repeatability: | <1mm (conductive medium); <10mm (insulating medium) |

| Response Time: | <0.5s |

| Delay: | 1~50s |

| High/Low Alarm: | Field configurable as HLFS (High Level Alarm Mode) or LLFS (Low Level Alarm Mode) |

| Spark Protection (for Sensor): | Built-in spark protection circuit |

| Electrical Interface: | M20*1.5 |

| Cable: | Dedicated connection cable between split electronic unit and sensor: standard 5m, maximum 50m |

| Process Connection: | NPT threaded mounting (standard), flange mounting (optional) |

| Enclosure Protection: | IP66 |

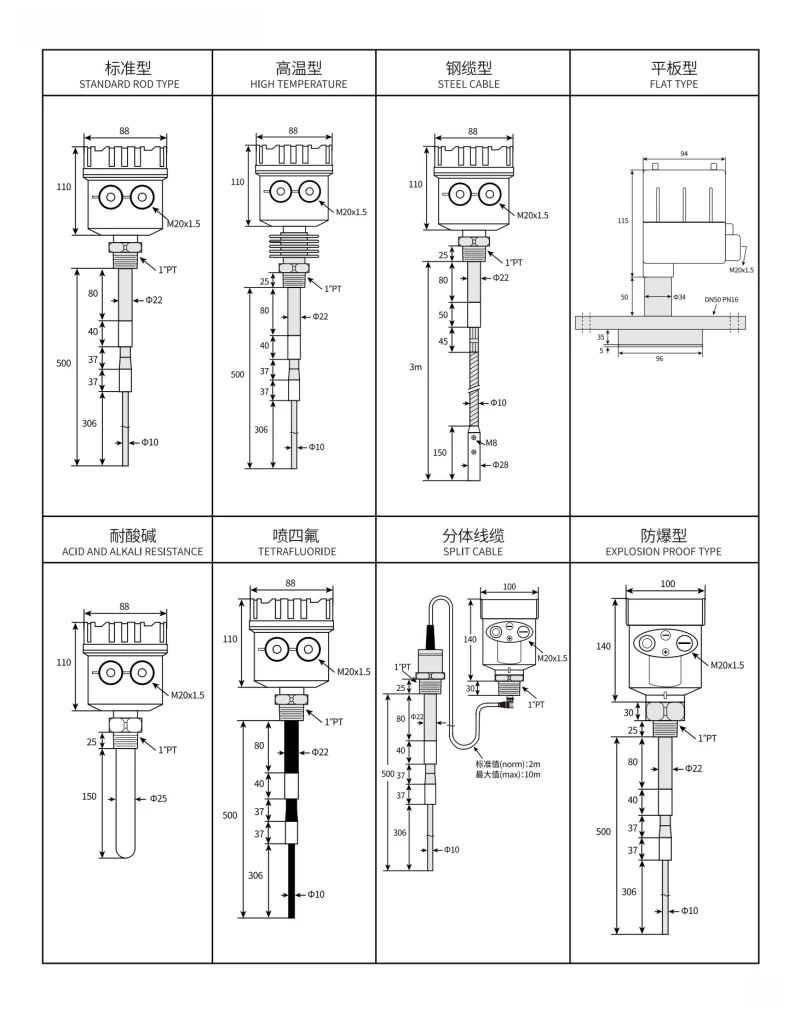

| Probe | |||

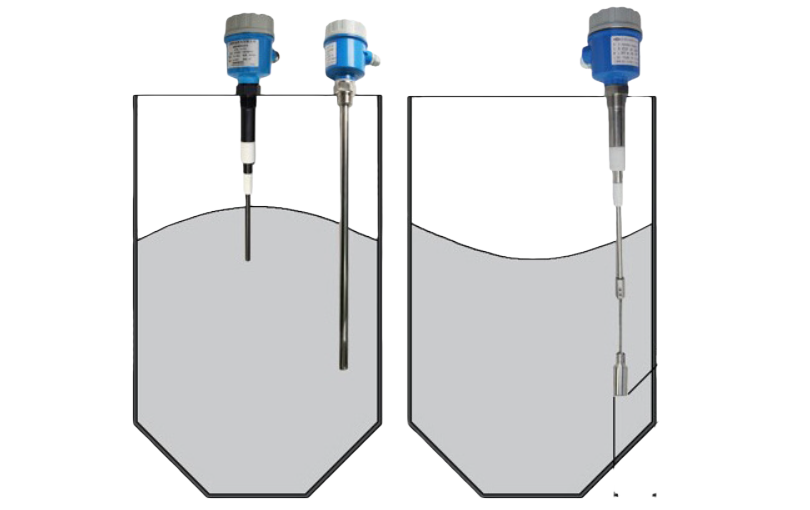

| Length | Rod type 150mm Minimum 1300mm Max | High temperature type 150mm Minimum 1300mm Max | Cable type 1000mm Minimum 25000mm Max |

| Wetted Materials: | PTFE shielding section, 304/316L | Ceramic isolator, 304/316L | 304/316L |

| Sealing material | Tetrafluoro | Tetrafluoro | Tetrafluoro |

| Thermal isolation length | L=250mm | L=450mm | optional |

| Extend: | Customized according to user requirements. | ||

RF Admittance Level Switch Working Principle

RF admittance is a new type of level control technology developed from capacitive level technology. It is more reliable, accurate, and widely applicable, preventing material buildup. It represents an upgrade from capacitive level technology.

RF admittance, in electrical terms, is the reciprocal of impedance. It is composed of resistive, capacitive, and inductive components. RF refers to the high-frequency radio spectrum, so RF admittance can be understood as measuring admittance using high-frequency radio waves.

When the instrument is working, the sensor, the tank wall, and the measured medium form an admittance value. As the level changes, the admittance value changes accordingly. The circuit unit converts the measured admittance value into a level signal output, realizing level measurement.

The most important difference between RF admittance level switches and capacitive technology lies in the diversification of measured quantities and anti-fogging technology.

The diversification of measured quantities by RF admittance level switches lies in measuring not only capacitance but also a combination of capacitance, resistance, and inductance, making the measurement more comprehensive and accurate.

Selection of RF Admittance Level Switches

To ensure the selected RF admittance level switch is well-matched to the field conditions and provides more accurate measurements, the following aspects should be considered when selecting an RF admittance level switch:

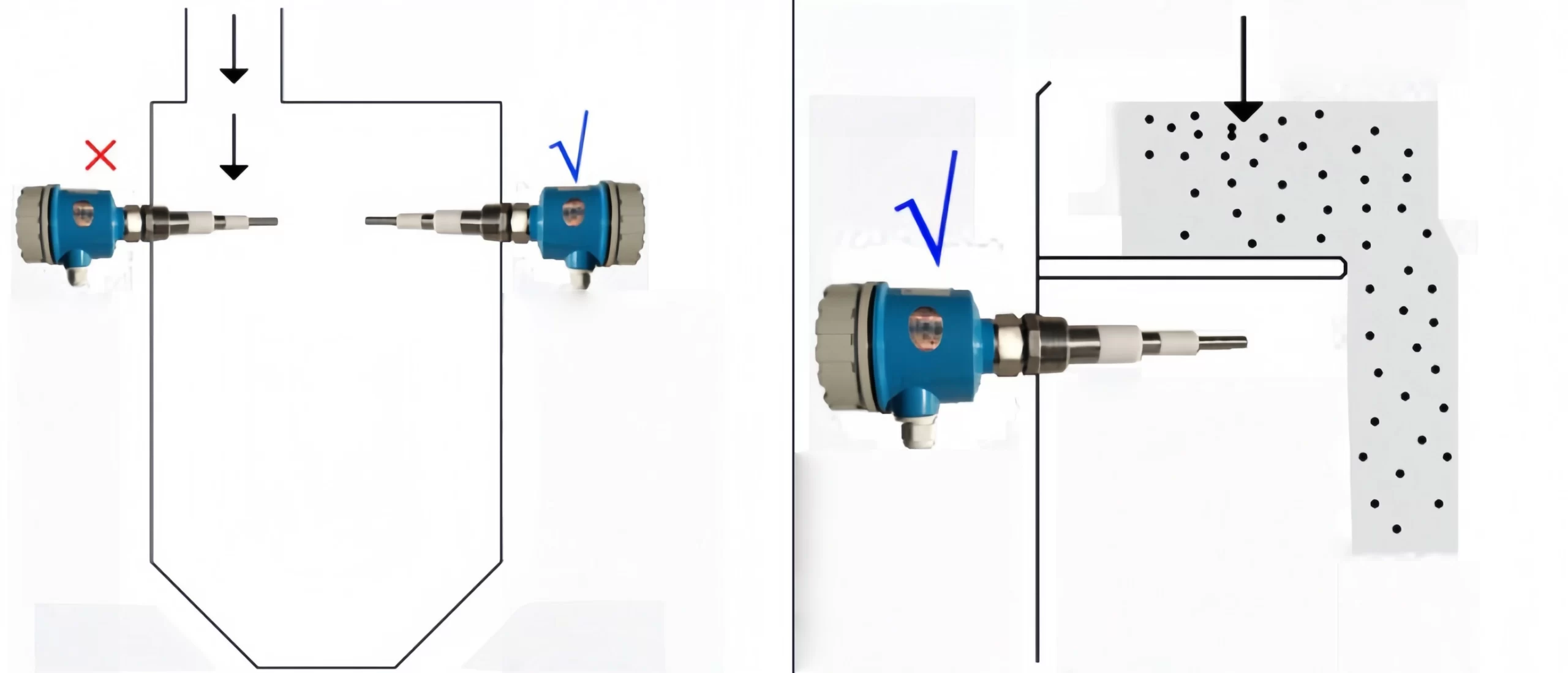

- Insertion Depth: Insertion depth is crucial for accurate level measurement. The insertion depth also depends on whether the instrument will be affected or damaged by material impact.

- Process Temperature: Different operating conditions have different temperature requirements, so selecting a level switch with a temperature range matching the specific field requirements is essential. If the instrument operates in a high-temperature environment, a level switch with a suitable temperature range should be selected.

- Process Connection: Process connections are critical components for installing the instrument on tanks, pipelines, and other equipment. They are generally divided into three categories: threaded, flanged, and clamped. When selecting a process connection, the appropriate size, thickness, and material should be chosen and customized according to the field requirements.

- Protection Function and Protective Electrode Length: If the field environment is dusty or has high humidity, an RF admittance level switch with a higher protection rating should be selected to avoid affecting instrument performance due to poor sealing. Sino-Inst RF admittance level switches have an IP66 protection rating, meeting user requirements in the field.

Furthermore, for harsher operating conditions, such as in ash hoppers of power plant ash conveying systems, RF admittance level switches with stainless steel protective sleeves should be selected to reduce probe damage from material impact. Sino-Inst protected RF admittance level switches are typically available with protective electrode lengths of 300mm and 590mm. Custom designs are also available upon request.

Featured Applications

Radio frequency (RF) admittance level switches are an improvement on traditional capacitance measurement technology, using RF admittance measurement to measure and control the level by sensing changes in the reactance (capacitive reactance and impedance) between the sensor and the tank body. They can be used for level monitoring and control of powdery, liquid, and solid materials.

They are particularly suitable and reliable for level measurement of fly ash and solid particles, especially in situations involving adhesive materials, corrosive media, and high-temperature, high-pressure environments. They have wide applications in industries such as petroleum, chemical, metallurgy, power, pharmaceuticals, food, papermaking, and building materials.

Specifically, RF admittance level switches are mainly used for level measurement in the following industrial applications:

- Power Industry: Coal piles, raw coal silos, fuel silos, pneumatic conveying systems, ash silos, etc.

- Metallurgical Industry: Ore bins, ore crushers, raw material silos, auxiliary material silos, blast furnaces, alumina powder silos, electrolytic cell buffer tanks, etc.

- Chemical Industry: Raw material and intermediate silos, reaction vessels, solid material silos, separators, etc.

- Pulp and Paper Industry: Raw material silos, storage towers, drying drums, chemical storage silos, etc.

- Cement Industry: Aggregate silos, raw material silos, cement silos, pulverized coal silos, slag storage silos, etc.

- Other Industries: Quarries, food processing, pharmaceuticals, environmental protection, shipbuilding, etc.

More Level Measurement and Control Solutions

Case: Non-Contact Material Level Measurement – Radar Level meter

What are Capacitive Level Sensors?

Choosing the Right Level Switch for Industrial Applications: A Complete Guide

Radar Gauge for Level Measurement

Case: Rotary Paddle Level Switch For Material Level Control

Understanding Liquid Level Measurement: Types, Uses and Best Technologies

Single & Multi Liquid Level Float Switches – Effective Level Control

Ultrasonic Level Transducer: Working Principle,Types and Benefits

Sino-Inst’s RF admittance level switches incorporate a shielding electrode between the measuring electrode and the grounding electrode to overcome the influence of deposits, ensuring signal accuracy. This unique electrode construction makes them particularly suitable for detecting a wide variety of materials and is unaffected by material adhesion.

We support customization of RF admittance level sensors, whether for high temperatures, high pressures, or viscous media. Please contact our sales engineers for customized solutions.

RF Admittance Level Switch - Applicable Solids and Liquids

The RF admittance level switch is a level detection device based on RF admittance technology, an upgrade from capacitive level technology. It is anti-fouling, more reliable, and more accurate. It is widely used for measuring liquids, slurries, and granular materials.

Product SKU: RF Admittance Level Switch - Applicable to Solids and Liquids

Product Brand: Sino-Inst

Product In-Stock: InStock

-1.jpg)