There are several types of flow meters designed to measure the flow of dirty water fluids, and they work in slightly different ways. The electromagnetic flow meter solution is best for measuring the flow of dirty water such as mining slurries, wastewater plants, etc.

Unlike standard water meters used for clean water applications, these specialized Dirty Water Flow Meters must function reliably in challenging conditions. This blog post explores dirty water flow meters in detail.

Challenges in Measuring Dirty Water Flow

Applications for dirty liquids are found in the water, wastewater, mining, mineral processing, power, pulp and paper, and chemical industries. Water and wastewater applications include custody transfer of liquids in force mains between water/wastewater districts.

- Solid particles and debris

- Viscosity and density variations

- Different compositions impact flow meter performance

- Corrosion and scaling

- Foaming and turbulence

To address these challenges, manufacturers design flow meters with robust materials, self-cleaning mechanisms, and advanced sensing technologies.

Varieties of Dirty Water Flow Meters: Let’s explore in detail

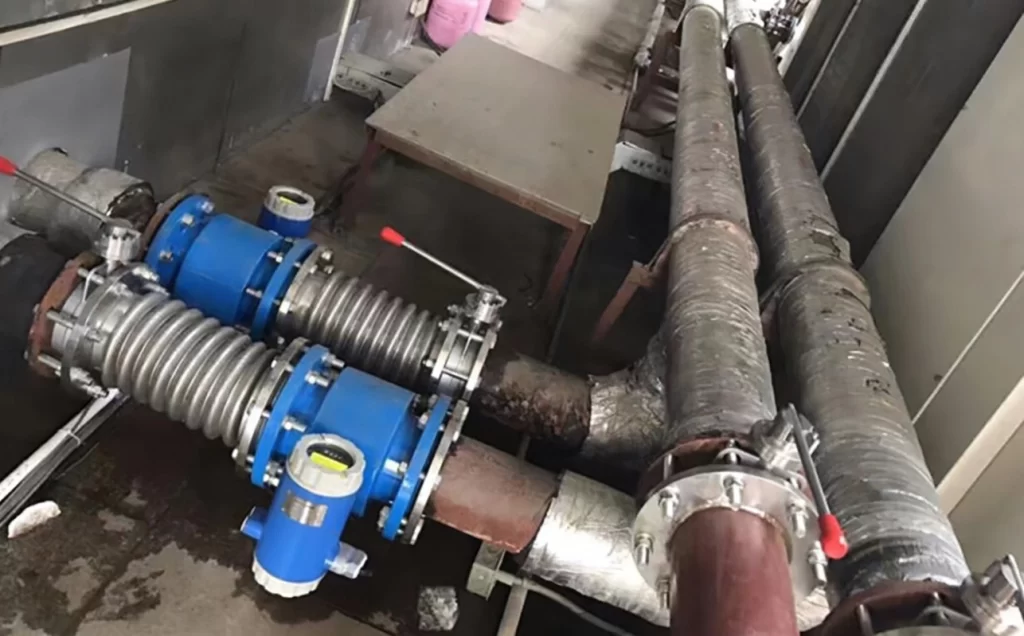

1. Electromagnetic Flow Meters (Mag Meters): Utilization as Dirty Water Flow Meter

Magnetic flow meters measure the velocity of conductive liquids in pipes, such as water, acids, caustic, and slurries. Magnetic flow meters can measure properly when the electrical conductivity of the liquid is greater than approximately 5μS/cm.

This flowmeter does not obstruct flow, so it can be applied to clean, sanitary, dirty, corrosive, and abrasive liquids.

Magnetic flow meters do not need much upstream and downstream straight run, so they can be installed in relatively short meter runs. Magnetic flow meters typically require 3-5 diameters of upstream straight run and 0-3 diameters of downstream straight run measured from the plane of the magnetic flowmeter electrodes.

Magnetic flow meters are used in water treatment plants to measure treated and untreated sewage, process water, and chemicals. Mining and mineral process industry applications include process water, process slurry flows, and heavy media flows.

With proper care to materials of construction, the flow of highly corrosive liquids (such as acid and caustic) and abrasive slurries can be measured. Corrosive liquid applications are commonly found in chemical industry processes and in chemical feed systems used in most industries. Slurry applications are usually found in the mining, mineral processing, pulp and paper, and wastewater industries.

Benefits:

- No moving parts, reducing maintenance.

- Works well with sludges and high solid content.

- High accuracy and reliability.

Limitations:

- Only works with conductive fluids.

- The initial cost is relatively high.

2. Ultrasonic Flow Meters: Utilization as Dirty Water Flow Meter

Ultrasonic meters measure flow using the Doppler Effect or Transit Time technology. The Doppler method is particularly useful for dirty water.

Clamp-On portable and fixed ultrasonic Doppler flow meters are hands-down and easy to deploy as a non-invasive, non-contact flow meter solution for projects that involve the measurement of dirty or debris-laden liquid.

This technology discharges ultrasonic pulses into a section of the piping system, where the signal is refracted off the flowing media within the liquid and then received back into a transducer.

This outgoing signal is measured against the received frequency-shifted signal, providing the site engineer with an accurate measurement of the system’s flow.

Benefits:

- The benefit of an Ultrasonic Doppler Flow meter is that it can be deployed quickly by simply clamping it onto the exterior of the pipe and programming it to account for pipe thickness and diameter.

- Works well with aerated or Particle-laden water.

- Low maintenance.

Limitations:

- Impurity particles are required to be less than 15%;

- Accuracy depends on proper sensor placement.

3. Coriolis Flow Meters: Utilization as Dirty Water Flow Meter

Coriolis meters measure mass flow directly by detecting changes in the vibration patterns of a U-shaped tube as liquid flows through it. It is the best accurate flow meter for sludge flow measurement.

Coriolis flow meters are commonly used in sludge flow measurement applications due to their ability to handle high-viscosity fluids and their resistance to clogging.

Benefits:

- Direct mass flow measurement unaffected by density variations.

- Works with highly viscous and non-Newtonian fluids.

Limitations:

- High cost compared to other types.

- Sensitive to external vibrations.

Fundamental Applications of Dirty Water Flow Meters

- Wastewater Treatment Plants

- Measuring inflow and outflow of sewage water.

- Monitoring sludge processing systems.

- Controlling chemical dosing in treatment processes.

- Industrial Effluent Monitoring

- Tracking discharge from factories to comply with environmental regulations.

- Measuring flow in cooling and process water systems.

- Storm Water and Drainage Systems

- Monitoring flow in municipal storm water channels.

- Detecting and managing flood risks.

- Mining and Slurry Handling

- Measuring slurry flow in mineral processing plants.

- Monitoring wastewater discharge from mining operations.

- Agricultural Irrigation and Runoff Management

- Tracking irrigation water mixed with fertilizers or sediments.

- Monitoring drainage water in large-scale farming.

More Flow Measurement Solutions

- Potable Water Flow Meters In Domestic Water Supply Systems

- The Right Saltwater And Seawater Flow Meter For Your Needs

- Guide for Raw Water And Fresh Water Flow Meters

- Electromagnetic Interference Resistant Flow Meters

- Helical Flow Meters: Accurate Flow Measurement For Challenging Applications

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Rotary Flow Meters for More Stable Measurement and Control Systems

- Fertilizer Flow Monitoring: Liquid Fertilizer Flow Meters

- Calorimetric Flow Meter: An Economical Solution For Hot Water Flow Measurement

By understanding the advantages and limitations of each type of Dirty water flow meter, businesses and municipalities can make informed decisions to improve efficiency, comply with regulations, and cut down operational costs.

Investing in the right dirty water flow meter not only ensures accurate measurement but also enhances the reliability of water management systems in challenging environments. Sino-Inst is always available in the customer service with its best flow measurement solutions.

-1.jpg)