A torque sensor is a device that converts physical changes in torque into a precise electrical signal. In laboratories and industry, it is used for basic research or quality assurance.

Strain gauge technology (DMS) is a powerful solution for rotating shaft measurements as well as long-term dynamic and static measurements. Piezoelectric reaction torque sensors have convincing features. For example, excellent overload protection, high signal resolution, and a wide frequency range.

Sino-Inst inline Torque Sensors & Torque Transducers are often used in the manufacture of viscometers, electric (pneumatic, hydraulic) torque wrenches, etc.

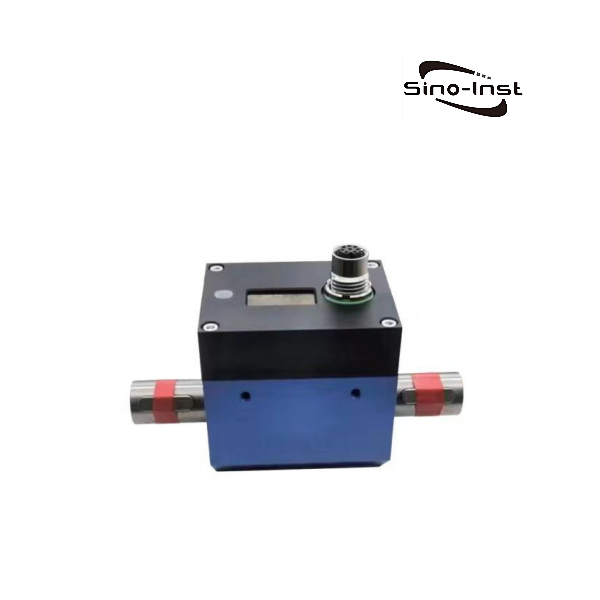

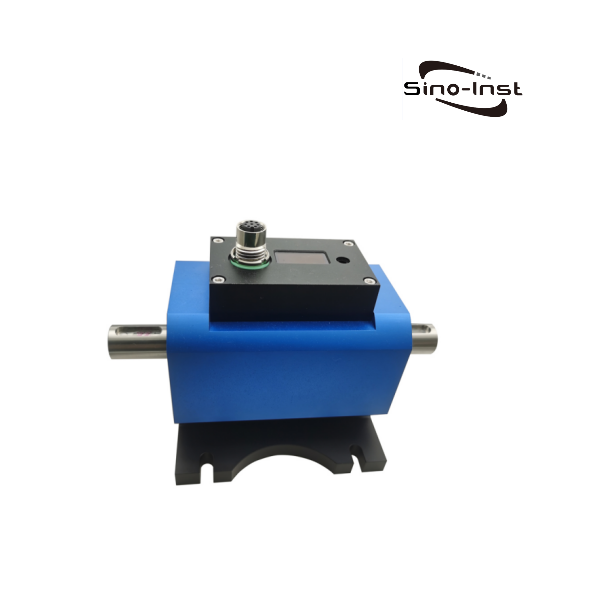

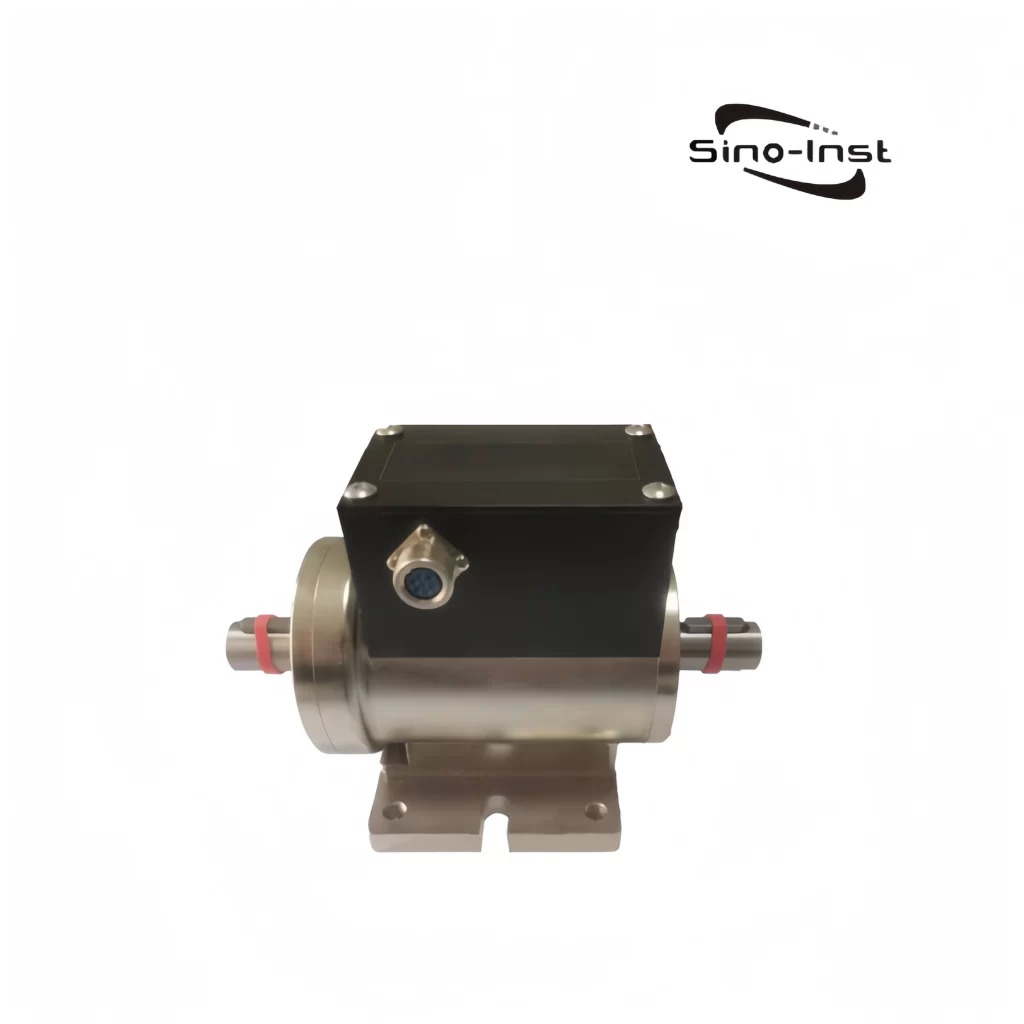

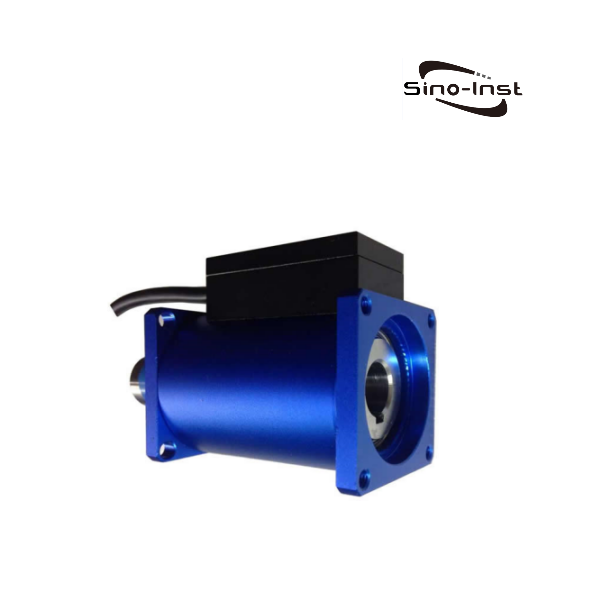

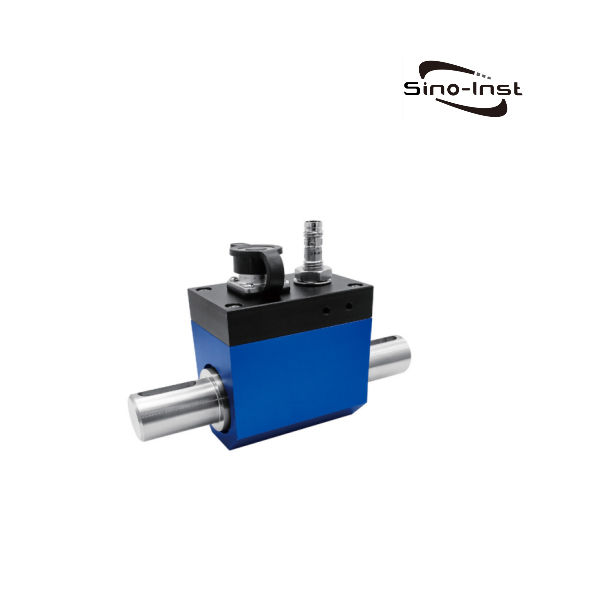

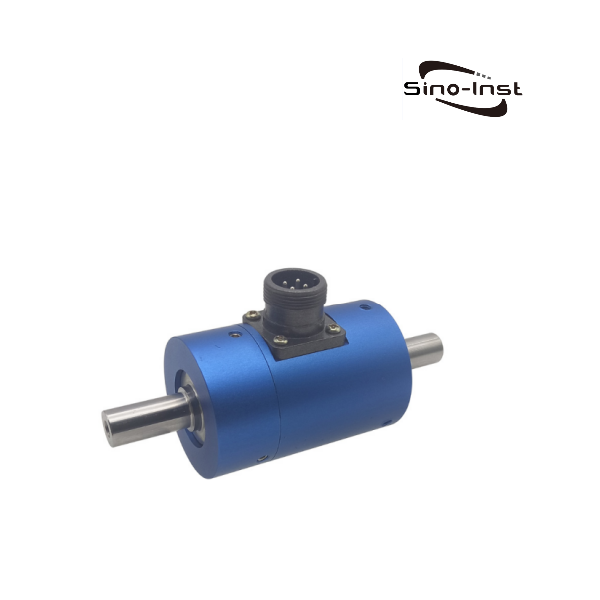

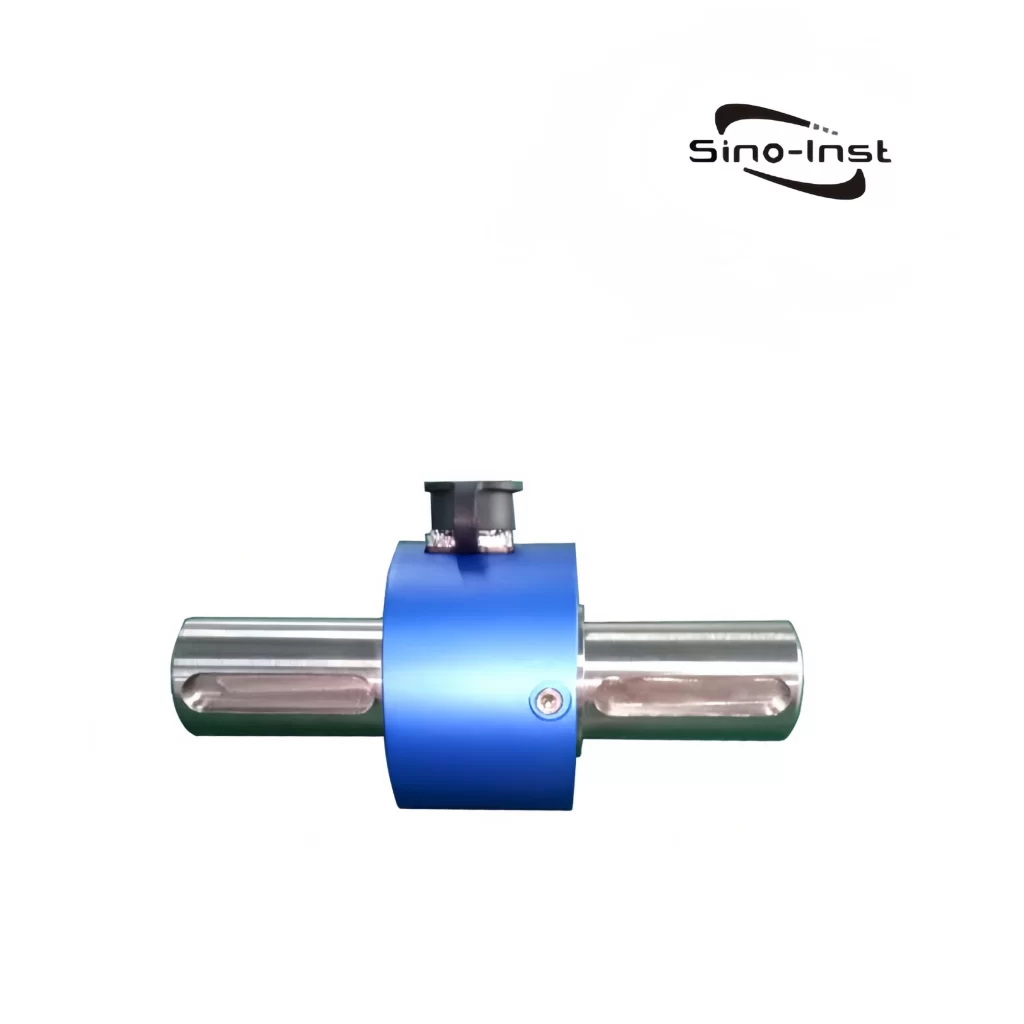

Featured Dynamic Torque Sensors/Rotary Torque Sensors

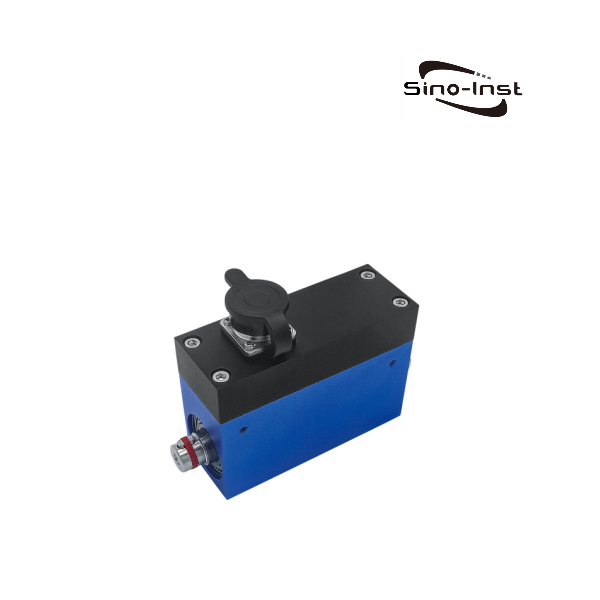

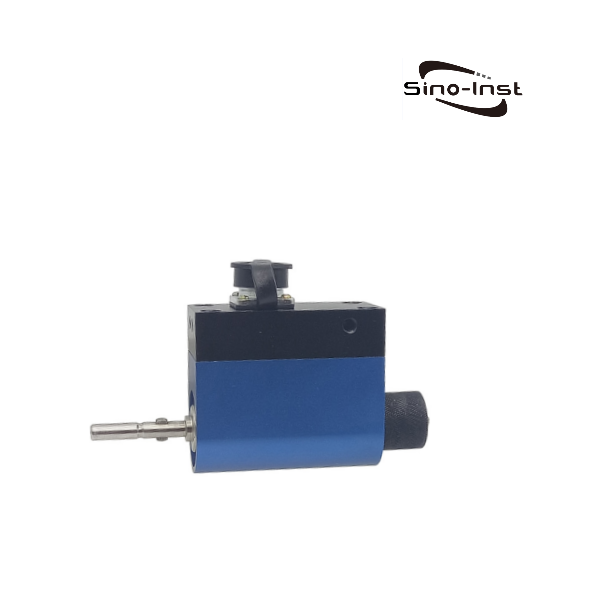

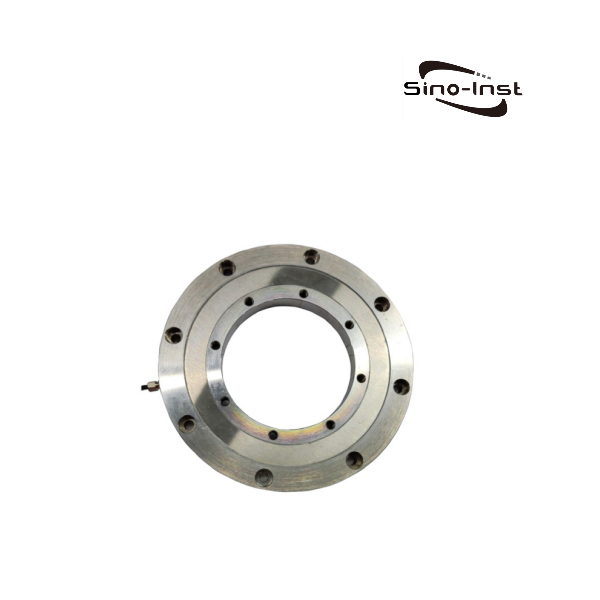

Featured Static Torque Sensors/Reaction Torque Sensors

What does a torque sensor do?

1. Measuring torque: The main function of the torque sensor is to measure torque, i.e. moment. It can measure static torque (such as torque at rest) and dynamic torque (such as torque during motion). The torque sensor can accurately measure the magnitude of torque and provide important data support for various industrial applications.

2. Controlling torque: The torque sensor can also be used to control torque. For example, in a car engine, the torque sensor can monitor the torque output of the engine. Then the engine is adjusted through the electronic control system to ensure the performance and safety of the engine.

3. Detecting load: The torque sensor can also be used to detect load. For example, in a crane, the torque sensor can monitor the load size of the crane, thereby ensuring the safe operation of the crane.

4. Measuring speed and power: In addition to torque, the torque sensor can also measure speed and power. This information is very important for understanding and controlling the working status of mechanical equipment.

5. Improving production efficiency: The use of torque sensors can improve production efficiency. By accurately measuring and controlling torque, problems caused by excessive or insufficient torque can be avoided. Thereby improving product quality and production efficiency.

Typical Applications for Torque Transducers

Where are torque sensors used? In the field of industrial automation, torque sensors are widely used in various mechanical equipment. Such as motors, reducers, drive shafts, etc., to measure and control the torque parameters of equipment.

Dynamic torque sensors and static torque sensors also differ in their application range.

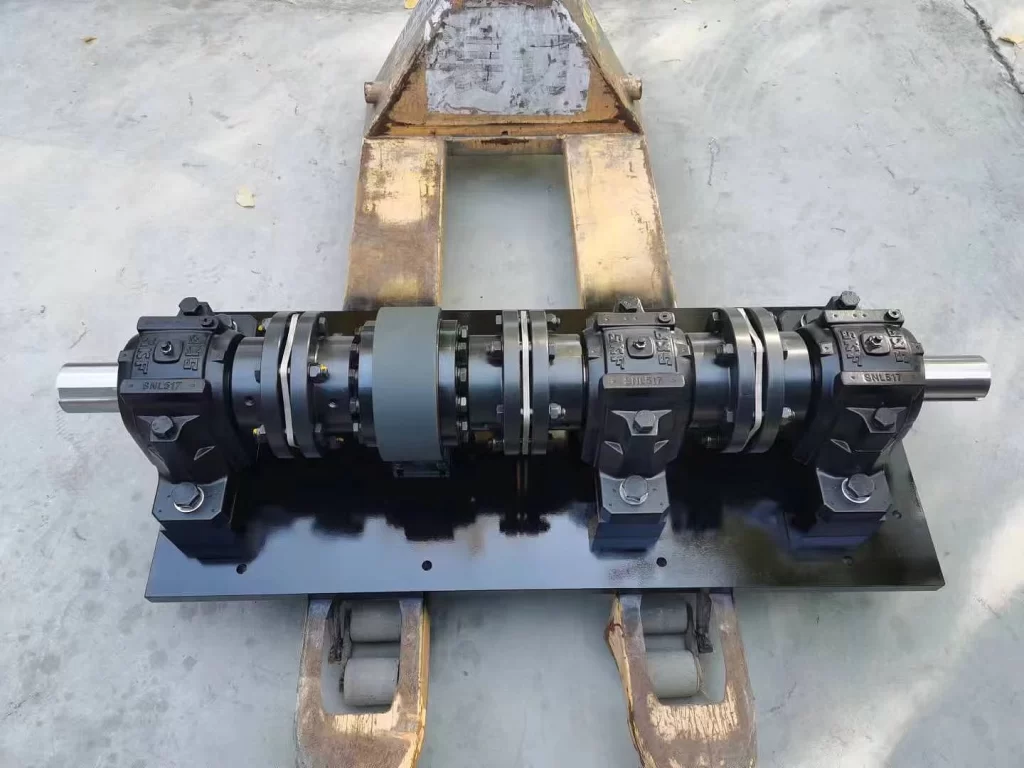

Dynamic torque sensors are widely used in various occasions where dynamic torque on rotating shafts needs to be measured. Such as monitoring and control of equipment such as motors, engines, reducers, etc.

In the automotive industry, dynamic torque sensors are used to monitor the torque state of the engine crankshaft. To control parameters such as fuel injection and ignition timing;

In motor control systems, they are used to monitor the operating status of the motor. Ensure the normal operation of the motor and prevent overload or underload.

In the aerospace field, dynamic torque sensors are used to measure the torque of aircraft engines, propellers and other components. To monitor and control the power state during flight.

Static torque sensors are more used for static or steady-state torque measurement.

Such as torque measurement and control of motors, reducers, drive shafts and other equipment in the field of industrial automation;

In the automotive industry, static torque sensors are used to measure the torque output of components such as engines and transmissions. To ensure the power performance and safety of the vehicle.

In addition, in process and process industries, the two types of torque sensors also have their own application scenarios and advantages.

More Measurement Solutions

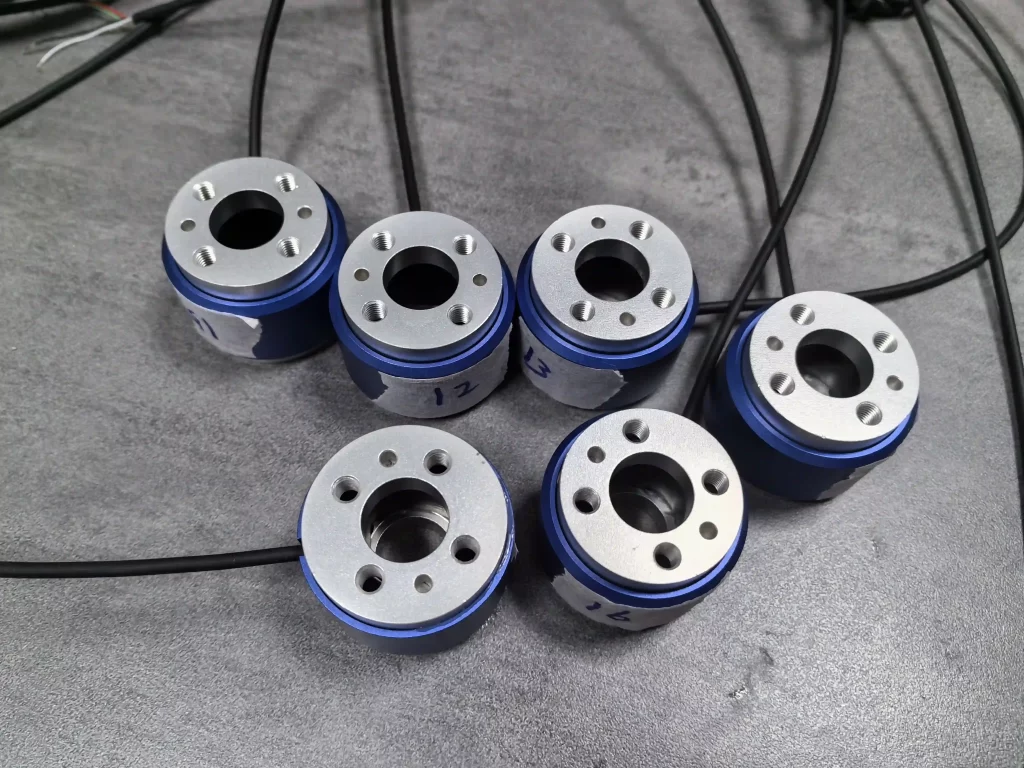

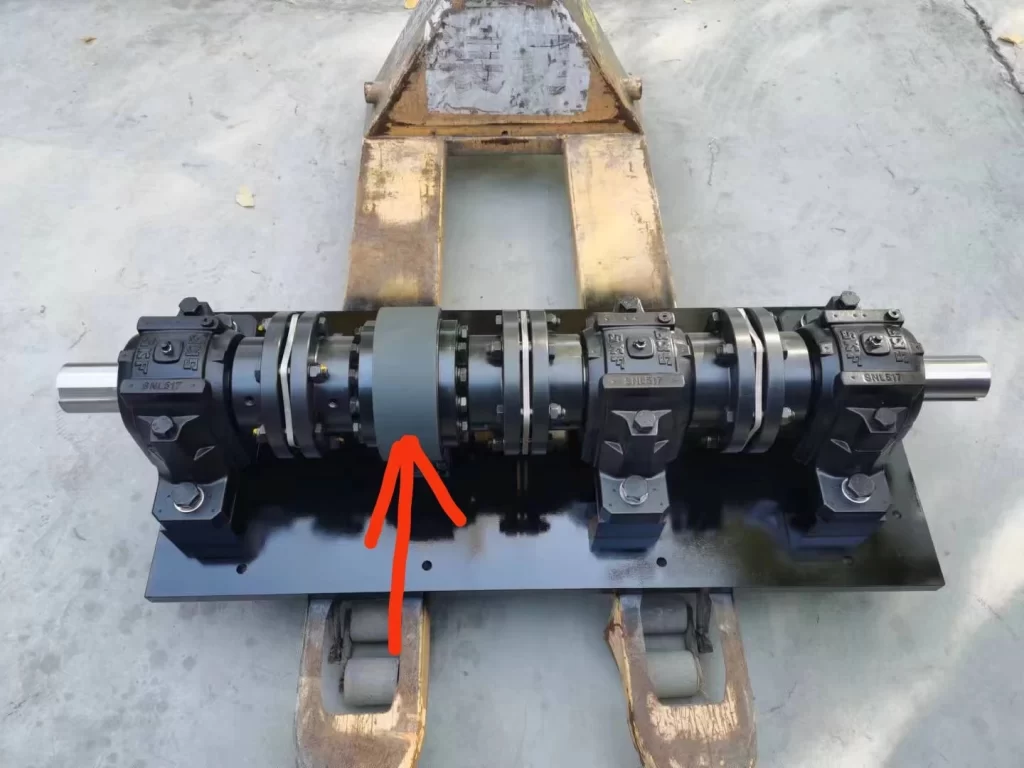

Sino-Inst offers a comprehensive range of industrial grade torque sensors. Our torque sensors feature a variety of designs to suit a variety of applications. These include shaft-to-shaft rotary, non-rotating shaft mount, inline, flange-to-flange, metric flange-to-shaft, sleeve extension and flange-to-shaft mount designs. They also feature optional encoders for speed measurement, double keyed ends and sleeve extension connections for drive and sleeve systems.

Need help ? Contact us now.

We will offer you the suitable Measurement Solutions !

-1.jpg)