What Is a Density Meter?

We are discussing industrial density meters here, not laboratory densitometers. Industrial density meters are devices specifically designed to measure fluid density, performing real-time online density detection and displaying data such as density and temperature. They also support outputs of 4-20 mA, 0-1000Hz, RS485 Modbus RTU, HART, and other signals, facilitating industrial process control.

Why is density monitoring needed?

Industrial density monitoring is primarily used for process and quality control, and can also assist in trade transactions.

For example, in the brewing industry, density continuously decreases during fermentation (sugar is converted into alcohol and CO₂). By tracking density changes, the fermentation process and endpoint can be accurately determined, thereby controlling the final alcohol content.

Or in the chemical industry, various chemical solutions (such as acids, alkalis, and alcohols) have a direct, linear relationship between concentration and density. Monitoring density is equivalent to real-time concentration monitoring. For example, in the production or use of sulfuric acid, measuring density directly determines whether it is 98% concentrated sulfuric acid or dilute sulfuric acid, which is crucial for reaction control and safety.

Alternatively, in the trade of petroleum, crude oil, and diesel, density testing can assess product quality. Furthermore, by measuring density and combining it with volume, the total mass of crude oil can be accurately calculated for trade settlement.

4 Types of Industrial Density Meters

The main types of industrial density meters include: tuning fork vibrating density meters, differential pressure density meters, optical density meters, and Coriolis density meters.

Tuning Fork Vibrating Density Meter

A tuning fork vibrating density meter is an instrument that measures the density of liquids online based on the principle of vibration. It is mainly used for continuous monitoring and process control in industries such as petrochemicals, food and beverage, pharmaceuticals, and mineral processing. Its working principle involves a piezoelectric element driving the fork to vibrate; changes in liquid density cause changes in the vibration frequency. The density value is calculated and output by an electronic unit, with a measurement range of 0.5–2.5 g/cc and an accuracy of ±0.002 g/cc. It supports temperature compensation and concentration percentage conversion.

Advantages: Simple installation, plug and play, maintenance-free. It can measure the density of mixed media containing solids or bubbles. Furthermore, our Sino-Inst tuning fork density meters support customization for various special materials such as 316L, Hastelloy, titanium alloy, zirconium, PTFE, and ceramics.

Disadvantages: This density meter is not ideal for measuring media that are prone to crystallization or scaling.

Differential Pressure Density Meter

The differential pressure online density meter continuously measures the concentration and density of liquids online using the differential pressure principle. This device is made of corrosion-resistant materials such as 316L stainless steel, featuring high reliability and simple installation and use. It supports multiple installation methods, including insertion and flange mounting, and outputs a 4-20mA standard signal with an LCD display.

Its working principle is based on Pascal’s principle P=ρgh, calculating density by measuring the vertical differential pressure. An integrated temperature sensor enables automatic temperature compensation. The measurement range is 0-3 g/cm³, with an accuracy of ±0.001 g/cm³, suitable for both flowing and stationary liquids. It is widely used in petrochemical, food and beverage, pharmaceutical, and environmental protection fields, meeting the measurement needs of high-temperature, high-viscosity, and corrosive media.

Optical Concentration Meter

An optical concentration meter is an instrument that measures the concentration of liquids or liquid mixtures using the principle of spectroscopy. It utilizes the propagation laws of spectra in liquids, sampling through a high-resolution spectral sensor, and then analyzing and processing the data using software to obtain the concentration patterns. Temperature compensation is then applied to determine the concentration of various liquids or liquid mixtures. A prerequisite for optical concentration meter measurements is that the liquid must have a certain degree of transparency.

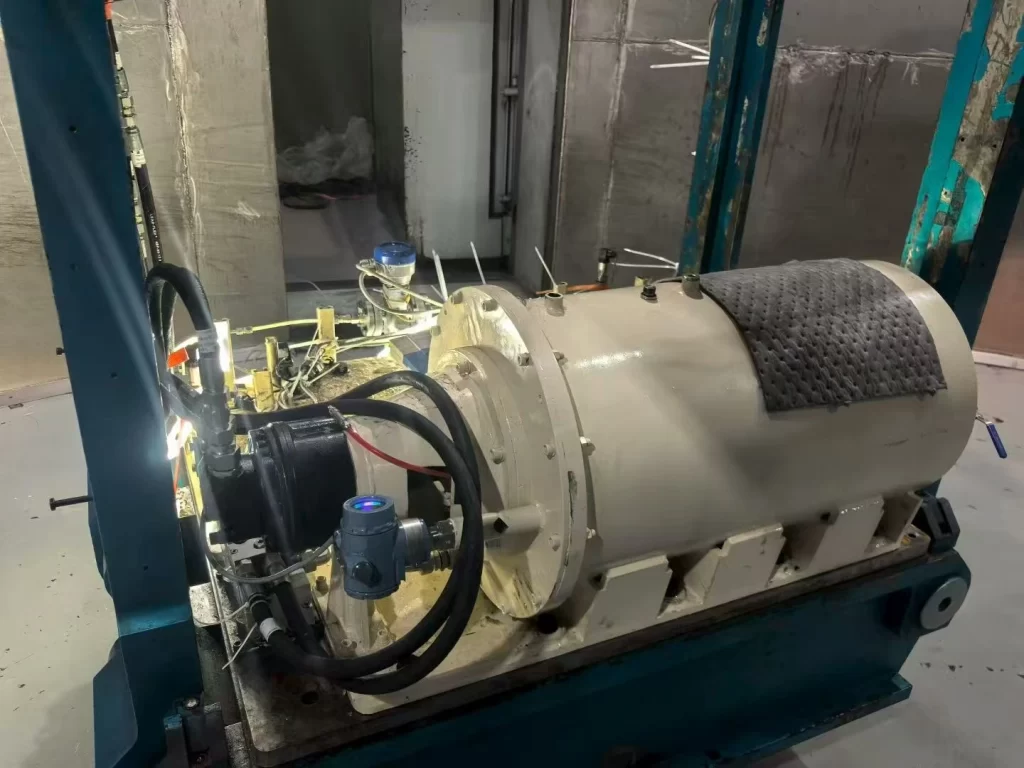

Coriolis Density Meter

A Coriolis density meter is an online density meter based on the Coriolis force principle, and is a derivative of the Coriolis mass flow meter. It is currently one of the most accurate density measurement instruments on the market. It is suitable for high-precision measurement of the density of flowing mixed solutions in pipelines. Normal accuracy is 0.001-0.002 g/cm³, with high accuracy reaching 0.0005 g/cm³.

It features high repeatability, stable measurement, and is unaffected by the type and properties of the liquid. It is largely unaffected by different operating conditions such as high and low pressure, flow rate, temperature, and the length of the preceding and following straight pipe sections. Pipe diameters range from DN1 to DN150, and the output signal is mostly 4-20mA. It supports HART communication protocol, RS485 communication, and bus communication (DP/FF/PA), enabling multi-functional remote transmission and control.

FAQ

Sino-Inst specializes in the research and development and manufacturing of process control instruments, including online density meters, concentration meters, pressure transmitters, flow meters, level gauges, and temperature gauges. We have extensive research and field application experience, particularly in online concentration and density measurement. We have established close partnerships with numerous universities, research institutes, and other scientific research organizations. We are now a comprehensive automation solution provider integrating instrumentation research and development, software development, and system integration.

We supply over 20 different digital density meters, widely used in factories across the US, UK, UAE, Indonesia, Singapore, and other countries. Online purchasing is supported.

-1.jpg)