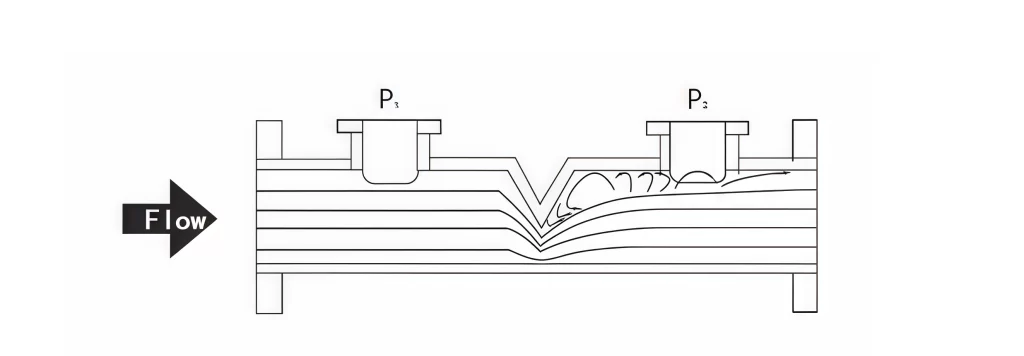

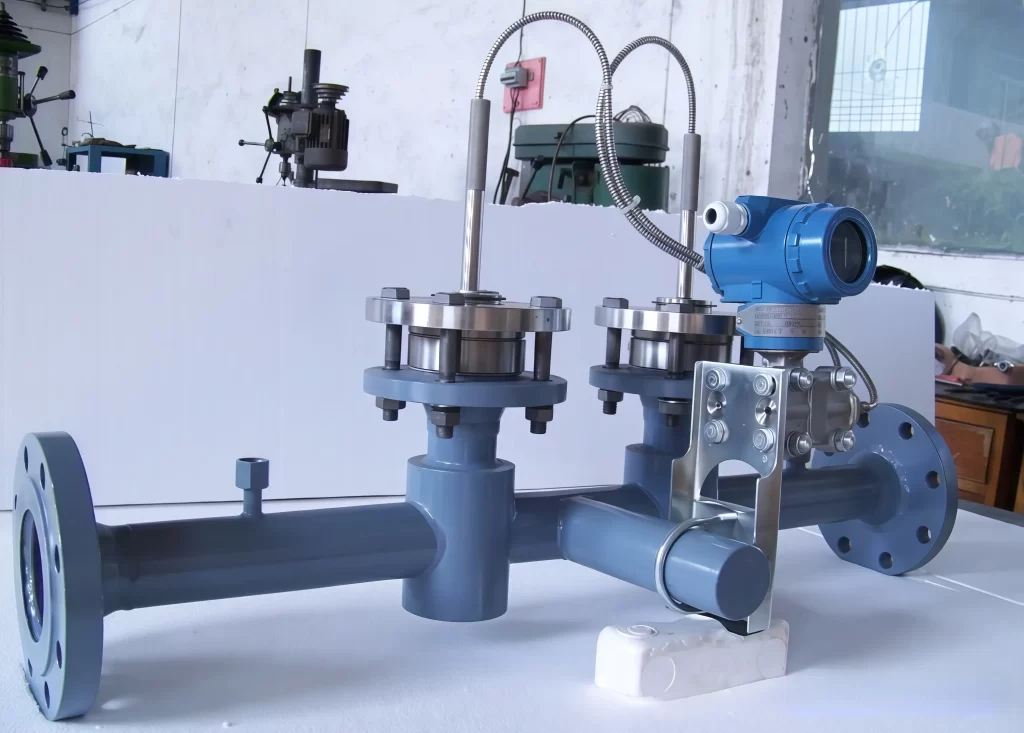

The wedge flow meter is a new type of flow measurement device for viscous and abrasive fluids.

It features a special structure with no stagnant zones and no clogging. It is robust and has a long service life. It can be used to measure liquids, gases, and steam. It is particularly suitable for measuring the flow rate of fluids with low flow velocities (Reynolds number as low as 300), high viscosity, and containing dust or solid particles. Examples include crude oil, fuel oil, oil slurry, asphalt oil, coal tar, wastewater, iron ore slurry, carbon black solution, two-phase fluids, and fluids containing solid particles.

Top Features

Technical Parameters

| Nominal Diameter (mm) | DN10–DN600 |

| Accuracy | Accuracy after calibration: 1%, 0.5%; without calibration: 3% |

| Medium Temperature | Maximum temperature: 400℃ |

| Material | Rectifying element material: 304, 316, 316L, HC, etc. |

| Body material: CS, 304, 316, 316L, HC, etc. | |

| Nominal Pressure | ≤42MPa |

| Connection Type | Flange connection |

| Pressure Tap Method | Threaded pressure tapping, flanged pressure tapping |

| Turndown Ratio | 0.417361111 |

| Applicable Medium | Suitable for gases, liquids, steam, and high-viscosity media |

| Straight Pipe Section | Upstream 3-16DN, downstream 3DN |

| Flange Standard | American standard, German standard, Chinese standard, etc. |

| Special standards according to user requirements | |

| Protection Class | See technical parameters of the selected differential pressure transmitter |

| Explosion-proof Rating | See technical parameters of the selected differential pressure transmitter |

| Ambient Temperature | See technical parameters of the selected differential pressure transmitter |

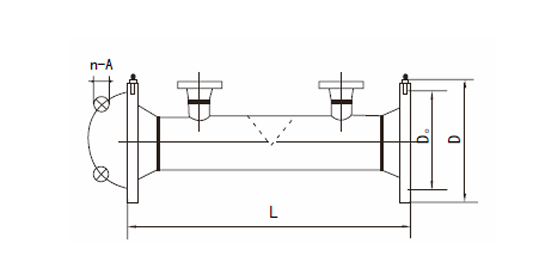

Wedge Flow Meter Dimensions

| Nominal diameter (mm) | Installation length L | Flange connection dimensions (DIN) Unit: mm | |||||||||

| PN1.0MPa | PN1.6MPa | PN4.0MPa | |||||||||

| DN | inch | ϕ D | ϕ D0 | n× ϕ A | ϕ D | ϕ D0 | n× ϕ A | ϕ D | ϕ D0 | n× ϕ A | |

| 15 | 1/2 | 500 | 95 | 65 | 4×14 | 95 | 65 | 4×14 | 95 | 65 | 4×14 |

| 20 | 3/4 | 500 | 105 | 75 | 4×14 | 105 | 75 | 4×14 | 105 | 75 | 4×14 |

| 25 | 1 | 500 | 115 | 85 | 4×14 | 115 | 85 | 4×14 | 115 | 85 | 4×14 |

| 32 | 1–1/4 | 500 | 140 | 100 | 4×18 | 140 | 100 | 4×18 | 140 | 100 | 4×18 |

| 40 | 1–1/2 | 500 | 150 | 110 | 4×18 | 150 | 110 | 4×18 | 150 | 110 | 4×18 |

| 50 | 2 | 500 | 165 | 125 | 4×18 | 165 | 125 | 4×18 | 165 | 125 | 4×18 |

| 65 | 2–1/2 | 600 | 185 | 145 | 4×18 | 185 | 145 | 4×18 | 185 | 145 | 8×18 |

| 80 | 3 | 700 | 200 | 160 | 8×18 | 200 | 160 | 8×18 | 200 | 160 | 8×18 |

| 100 | 4 | 700 | 220 | 180 | 8×18 | 220 | 180 | 8×18 | 235 | 190 | 8×22 |

| 125 | 5 | 800 | 250 | 210 | 8×18 | 250 | 210 | 8×18 | 270 | 220 | 8×26 |

| 150 | 6 | 800 | 285 | 240 | 8×22 | 285 | 240 | 8×22 | 300 | 250 | 8×26 |

| 200 | 8 | 900 | 340 | 295 | 8×22 | 340 | 295 | 12×22 | 375 | 320 | 12×30 |

| 250 | 10 | 1000 | 395 | 350 | 12×22 | 405 | 355 | 12×26 | 450 | 385 | 12×33 |

| 300 | 12 | 1100 | 445 | 400 | 12×22 | 460 | 410 | 12×26 | 515 | 450 | 16×33 |

| 400 | 16 | 1200 | 565 | 515 | 16×26 | 580 | 525 | 16×30 | 660 | 585 | 16×39 |

| 500 | 20 | 1400 | 670 | 620 | 20×26 | 715 | 650 | 20×33 | 755 | 670 | 20×42 |

| 600 | 24 | 1600 | 780 | 725 | 20×30 | 840 | 770 | 20×36 | 890 | 795 | 20×48 |

The above dimensions are for reference only and can be customized.

Wedge Flow Meter Installation

- The wedge-type sensor can be installed and used on horizontal or vertical pipes. When installed vertically, the fluid should flow from bottom to top.

- The flow direction mark on the wedge-type sensor housing should be consistent with the fluid flow direction.

- When flange mounting, the sealing gasket must not protrude into the flow meter pipe.

- The flow control valve is installed downstream of the sensor.

- Sensor straight pipe section length: 3-16DN upstream, 3DN downstream.

- When measuring fluid temperature, the temperature transmitter is installed 5D downstream of the sensor; when measuring fluid pressure, the pressure transmitter is installed 10D upstream of the sensor.

- Depending on the nature of the measured medium and the relative position of the wedge-type sensor and the differential pressure transmitter (or intelligent differential pressure flow totalizer), the differential pressure signal pipeline installation should comply with on-site pipeline installation process requirements.

- For wedge-type flow meters installed on horizontal or inclined process pipelines, the drain hole should be located directly above the pipe for liquid media, and directly below the process pipe for gases and steam.

Key Industrial Applications for Wedge Flow Meters

Our wedge flow meter is engineered specifically for the “difficult” fluids that cause standard meters to fail. We focus on harsh process flow measurement where high viscosity, low Reynolds numbers, and suspended solids are the norm.

Slurries and Sludge in Mining and Wastewater

Standard meters clog when facing fluids with suspended particles or fibers. Our slurry flow meter design utilizes a V-shaped throttle that allows solids to pass freely without accumulation. This makes it ideal for wastewater treatment plants handling raw sewage and mining operations moving ore slurries.

Heavy Oils, Asphalt, and Bitumen

For the oil and gas sector, viscous fluid flow measurement is a critical challenge. We handle fluids with viscosities up to 500 mPa.s. This includes heavy oil, tar, asphalt, and bitumen. The wedge structure maintains accuracy even when the fluid is thick and moving slowly (low Reynolds numbers).

Abrasive Chemicals and Pulp Processing

In chemical and paper industries, equipment wear is a major concern. As an abrasive media flow meter, our device withstands the erosion caused by pulp suspensions and crystallizing liquids. The robust structure ensures long-term reliability without the need for frequent maintenance or cleaning.

Dirty Gases and Solids-Laden Liquids

Whether it is coal-water slurry or dirty gases containing particulate matter, our solids-containing fluid meter delivers stable differential pressure readings. The self-cleaning nature of the wedge element prevents the “dead zones” where debris typically builds up, ensuring consistent performance in dirty gas applications.

More Technical Support

DP Transmitter for Flow Measurement

Guide to Flow Measurement Devices: Types and Selection

A Practical Guide to 5 Different Types of Flow Elements

Quick Guide: Clamp on Ultrasonic Flow Meter Installation

Flowmeter Installation: Upstream and Downstream Straight Run Requirements

Case Study: Paint Flow Measurement

Everything You Need To Know About Propane Gas Flow Meters

Annubar Flow Measurement: Principles, Applications, And Advantages

Order Guide

Wedge-type flow meters are often customized based on the user’s actual measurement parameters. Therefore, you need to confirm the following parameters in advance:

- Measured Medium: Air, Liquid, or Steam

- Medium Temperature (°C)

- Medium Viscosity (mPa.s)

- Medium Pressure (MPa)

- Unit Selection: L/h, m³/h, Nm³/h, kg/h, t/h

- Minimum-Normal-Maximum Flow Rate Range:

- Installation and Environmental Conditions:

- Process Pipe Outer Diameter:

- Process Pipe Inner Diameter:

- Pipe Material:

- Installation Orientation: Vertical, Horizontal, or Other

- Connection Flange Standard:

- Power Supply:

- Explosion-proof Requirements: Intrinsically Safe, Flameproof

- Explosion-proof Class:

- Protection Class:

- Other Requirements:

For viscous sludges, abrasive slurries, or thick oils that can clog standard flow meters, wedge flow meters are an economical and reliable option that will not be blocked by high-viscosity media.

Sino-Inst manufactures and supplies wedge flow meters, supporting customization for high temperature, high pressure, and high viscosity applications. Please feel free to contact us!

Wedge Flow Meter for Viscous and Abrasive Fluids - Sino-Inst

The wedge flow meter is a new type of flow measurement device for viscous and abrasive fluids.

Product SKU: Wedge Flow Meter for Viscous and Abrasive Fluids

Product Brand: Sino-Inst

Product In-Stock: PreOrder

5

-1.jpg)