Sino-Inst manufactures and sells high-quality thermal mass flow meters that can directly measure the mass flow rate and volumetric flow rate of air and other dry gases.

Thermal mass flow meters are based on the principle of thermal diffusion and accurately measure gases using the isothermal difference method. They measure the fluid’s mass flow rate by utilizing the temperature field change generated when a fluid flows through a pipe heated by an external heat source, or by using the relationship between the energy required to heat the fluid to a certain temperature rise and the fluid’s mass.

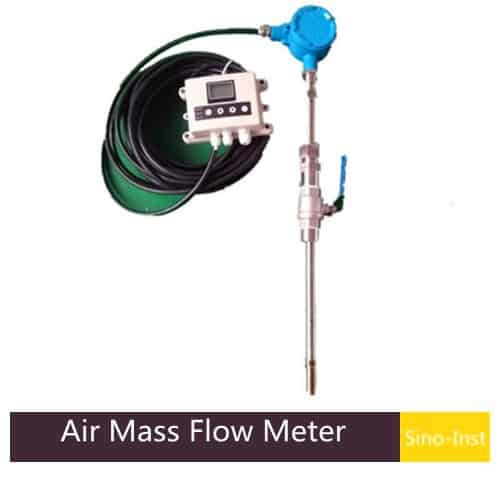

We, Sino-Inst, supply inline thermal mass flow meters and insertion thermal mass flow meters.

Featured Thermal Gas Mass Flow Meters

Data Sheet

FAQ

More Technical Support and Solutions

Accurate Flare Gas Measurement Using Thermal Mass Flow Meters

Case Study: Custom Thermal Mass Flow Meter For Nitrogen Flow Measurement

Inline Thermal Mass Flow Meters | Sino-Inst

Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

Thermal Mass Flow Meter Technology

Our Sino-Inst thermal gas mass flow meters are true mass flow meters, directly measuring the mass flow rate or standard volumetric flow rate of gases. No temperature or pressure compensation is required, making measurement convenient and accurate.

Thermal gas mass flow meters can measure the flow rate of natural gas, coal gas, liquefied petroleum gas, flare gas, hydrogen, and other gases. They are widely used in steel mills, coking plants, cement plants, glass factories, and other industries.

If you require a customized thermal mass flow meter, please feel free to contact us.

-1.jpg)