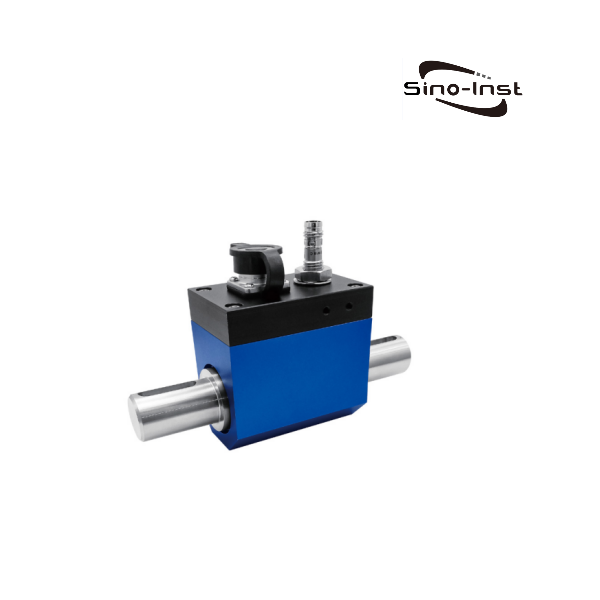

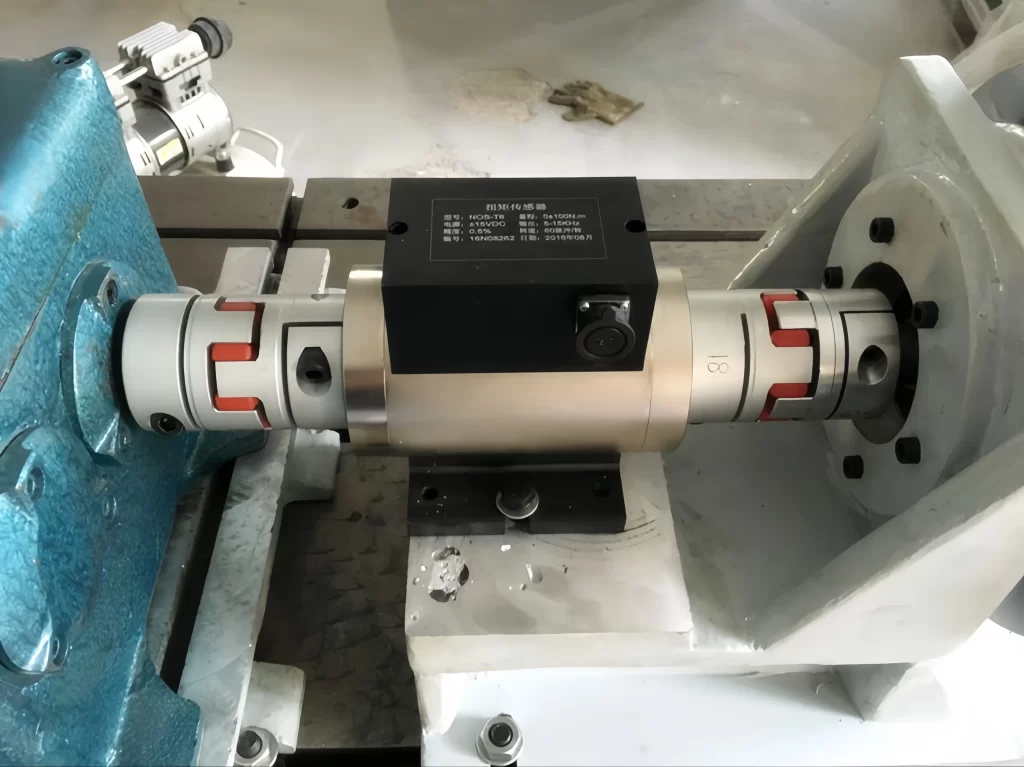

Shaft Torque Sensors are devices that can directly measure the torque of a rotating shaft. This refers to the mounting structure of the torque sensor, such as a flange torque sensor. Compared with flange-mounted torque sensors, shaft-mounted torque sensors take up less space and are relatively inexpensive.

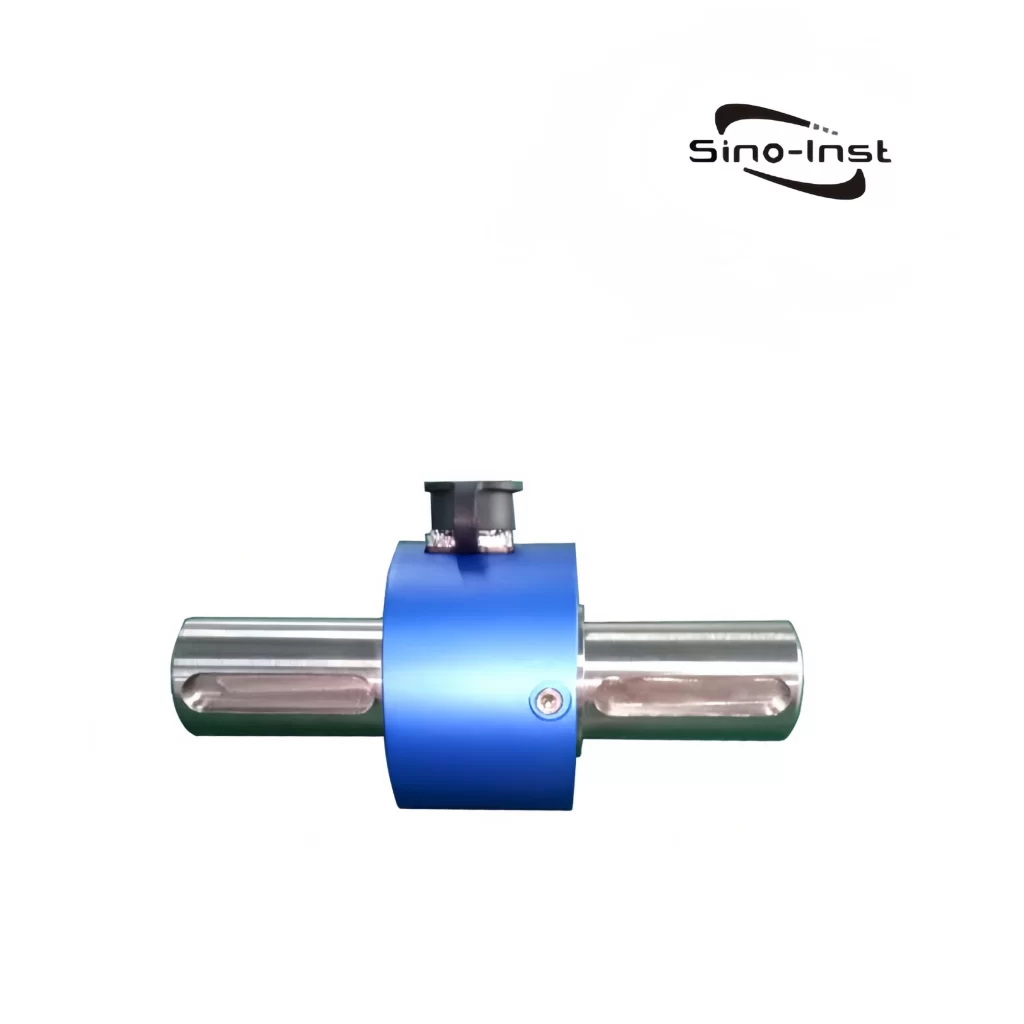

Shaft Torque Sensors can be dynamic torque sensors or static torque sensors. By detecting the tiny deformation, stress or phase difference caused by the torque when the shaft transmits power, the mechanical torque signal is converted into an electrical signal output. This enables the monitoring of torque.

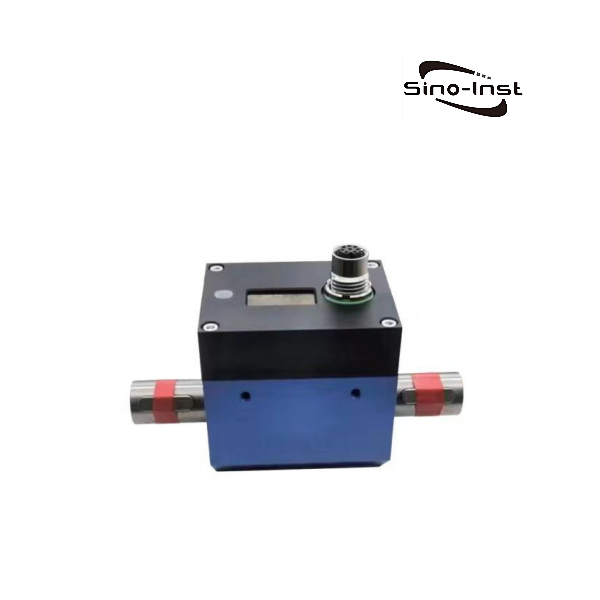

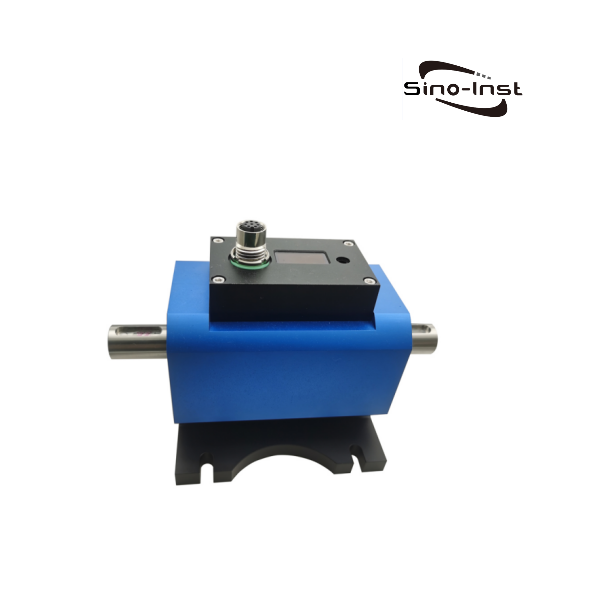

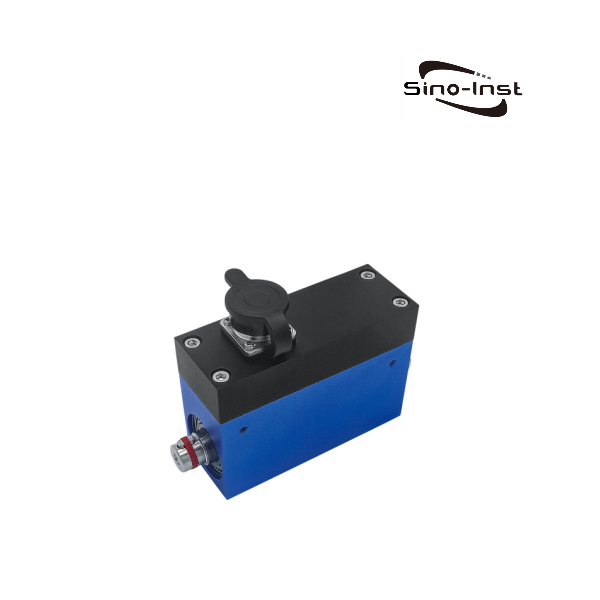

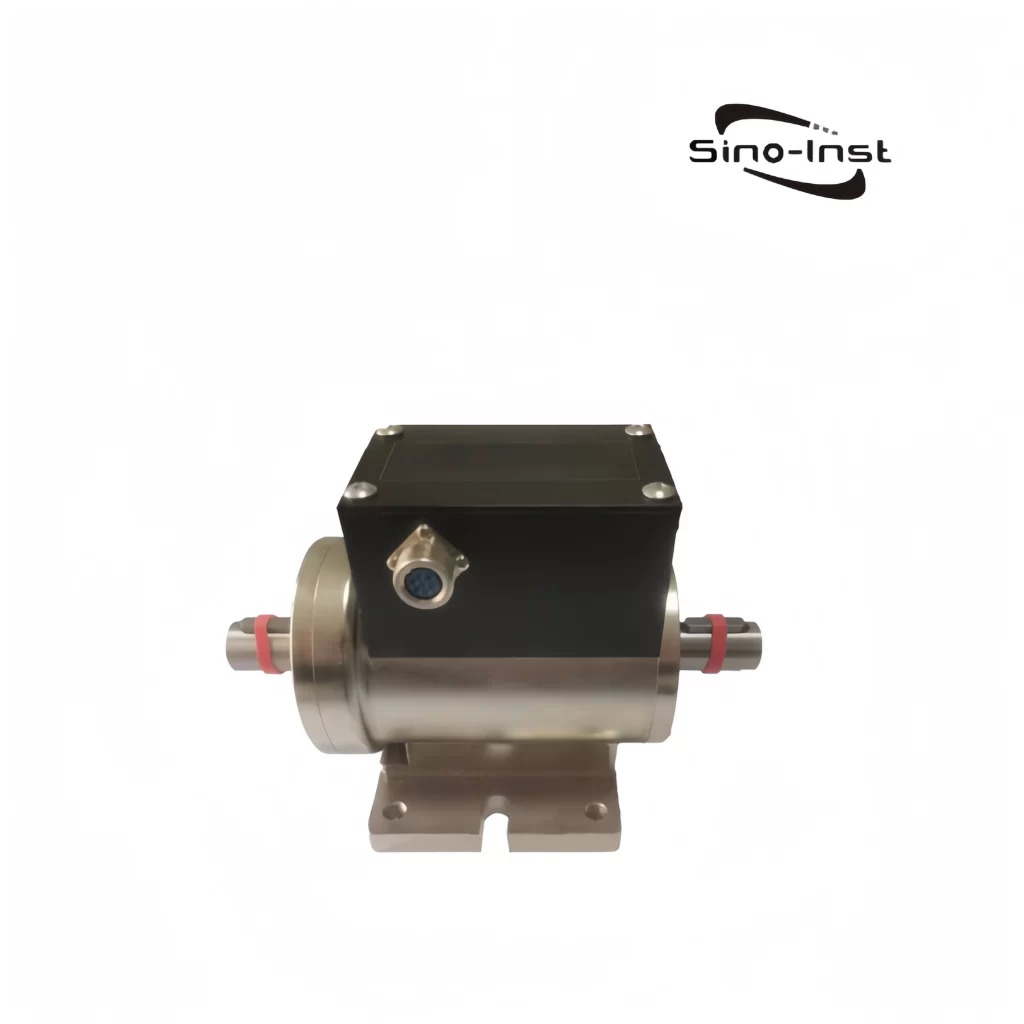

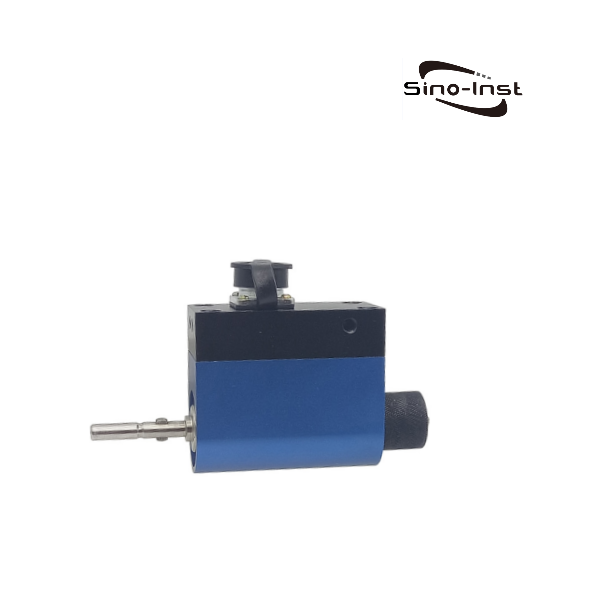

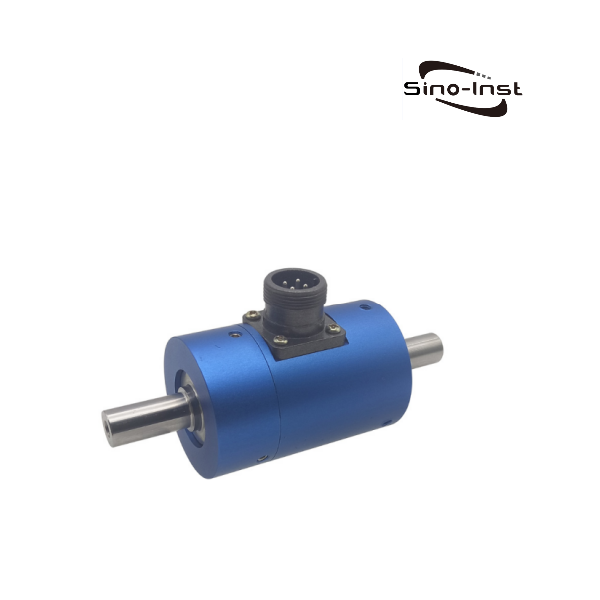

Featured Shaft Torque Sensors

Working Principle of Shaft Torque Sensors

The most common principle of shaft torque sensor is strain gauge principle.

Strain gauge technology: Most torque sensors are based on strain gauge technology. Strain gauges are attached to the shaft, and when the shaft is subjected to external torque, micro deformation occurs. The resistance value of the strain gauge changes. It is converted into a voltage signal through a bridge circuit.

Magnetoelastic or optical technology: Some sensors use magnetostrictive effect or laser interferometry principle to measure torsional deformation non-contact.

More Torque Measurement Solutions

What is Contactless Torque Sensor and Technology?

Industrial Applications of Torque Sensors

What Is a Rotary Torque Sensor?

How to Measure Torque?

Shaft Torque Sensors are commonly used as test/audit tools for motors, torque measurement tools, turbines, and generators. They can also be used for feedback control, torque monitoring, test bench efficiency analysis, and measuring torque on rotating shafts using strain gauges.

Sino-Inst supplies various types of Shaft Torque Sensors. They meet different range, speed, output, and other requirements. If you need to purchase, or have any related questions, please feel free to contact us!

-1.jpg)