A rotameter, also known as a variable area flow meter, is widely used to measure the flow rate of various gases, especially in situations where no power supply is available. Whether measuring air, oxygen, nitrogen, carbon dioxide (CO2), or other gases, rotameters provide reliable and accurate results.

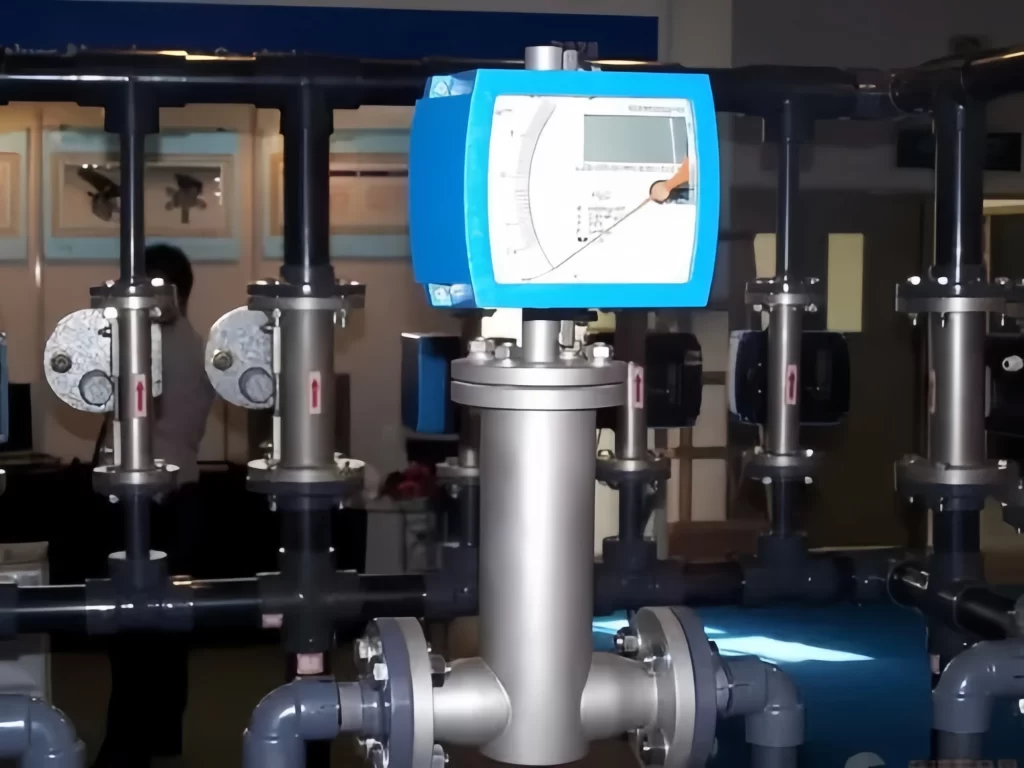

Of course, rotameters can also be configured as electronic smart devices, providing local digital display and outputs such as 4-20mA and switch signals. This has led to rotameters occupying a larger share of the industrial gas flow measurement market.

To begin with: What is a Rotameter?

Rotameter or The Variable Area Flow meter is one of the oldest and most mature principles in flow measurement with its simple design. A float rises inside a conically shaped tube as the flow increases and its position on a scale can be read off as the flow rate. Since this measuring method is purely mechanical, it is as simple as it is trustworthy.

Variable Area/Rotameters Flow Meter and Switches

Rotameters for Different Gases

When measuring gases, the type of gas can significantly affect the choice of the rotameter. Below, we will explore several types of rotameters designed for specific gases, including air, oxygen, nitrogen, CO2, and high-pressure applications.

1. Air Rotameter

Air can be measured using a rotameter.

Air and compressed air are widely used in industrial production, serving as power sources, production aids, and for protecting equipment. They are indispensable in many aspects of laboratories, HVAC systems, pneumatic control systems, food processing, pharmaceuticals, and electronics.

When selecting a metal rotameter for measuring air flow, it is important to consider the pressure and temperature of the pipeline. Conventional metal rotameters have a maximum pressure rating of 4 MPa. If the air pipeline pressure exceeds this limit, a specially designed high-pressure metal rotameter is required.

2. CO2 Rotameter

A CO2 rotameter is used in critical measurements in various industries, including beverage carbonation, environmental monitoring, and laboratory experiments.

Since CO2 has different density and viscosity properties than air, a CO2 rotameter must be specifically calibrated for accurate measurements.

For instance, in the beverage industry, CO2 is injected into soft drinks and beer to create carbonation, and precise control over CO2 flow is essential for product consistency. CO2 rotameters are also used in environmental applications to monitor CO2 levels in the atmosphere or in enclosed spaces to ensure proper ventilation.

Calibration for carbon dioxide (CO₂)

- High density: Carbon dioxide is denser than air, and the flow behavior differs significantly from lighter gases like nitrogen and oxygen. Accurate calibration should take the gas’s density into account.

- Pressure sensitivity: CO₂ is sensitive to changes in pressure, so calibration should be done at specific pressure points to account for any compressibility effects.

3. Oxygen Rotameter

The oxygen rotameter is designed to measure the flow of oxygen, often used in healthcare applications, particularly in oxygen therapy and medical gas systems.

Given the potential health hazards associated with oxygen systems, oxygen rotameters are often built with high precision and are regularly calibrated to ensure accuracy and safety.

Calibration for oxygen (O₂)

- High reactivity: Oxygen is highly reactive and can cause combustion or degradation of certain materials. Ensure that the rotameter’s components are oxygen-safe.

- Calibration factors: Oxygen has a low viscosity, so it flows differently than gases with higher viscosity like carbon dioxide. Special attention should be paid to the density and compressibility of oxygen.

4. Nitrogen Rotameter

The flow of nitrogen is often measured using rotameters to ensure the desired flow rate is maintained. Since nitrogen is a relatively low-cost, widely available gas, accurate nitrogen flow control is vital in many industrial operations to prevent waste and ensure the quality of the final product.

Calibration for nitrogen (N₂)

- Inert nature: Nitrogen is an inert gas and doesn’t react with other substances. However, its low viscosity and compressibility should still be considered during calibration.

- Flow consistency: Nitrogen is often used as a calibration standard for other gases, so accurate calibration is crucial.

5. Chlorine Gas Rotameter

Chlorine gas (Cl₂) is a strong oxidizing, toxic, and easily liquefied gas widely used in chemical, water treatment, and pharmaceutical industries. However, due to its strong corrosiveness, significant density variations, and high safety requirements, conventional flowmeters struggle to provide stable measurements.

Metal tube flowmeters with PTFE (Teflon) lining can measure chlorine gas flow. Compared to other gas flowmeters made of special materials (such as Hastelloy or tantalum), they offer significant cost savings.

Read more about Comprehensive Guide On Chlorine Flow Meters.

High-Pressure Rotameter

High-pressure rotameters are frequently used in industries like natural gas, petrochemical, and gas distribution networks, where accurate flow measurement at elevated pressures is nitpicking.

Unlike standard rotameters, high-pressure versions are made to withstand higher mechanical stresses and are oftentimes armored with stronger materials and enhanced sealing mechanisms to ensure accuracy and durability under pressure.

These devices may also feature specialized floats and tapered tubes to maintain consistent readings despite the fluctuating pressures that can occur in high-pressure systems.

The key to using a high-pressure rotameter effectively is understanding the impact of pressure on gas density and viscosity, as these factors can alter flow characteristics. High-pressure rotameters are often calibrated for specific operating conditions to ensure they provide accurate readings even under challenging conditions.

Application of High-pressure Rotameter

- Used to monitor and control flow rates of various chemicals in manufacturing processes.

- Monitoring flows in refineries and processing plants.

- Common in laboratory settings for precise flow measurement during experiments.

More Flow Measurement Solutions

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

- Guide for High Pressure Flow Meters – Industrial Liquid & Gas Measurement

- Guide To Low Temperature Flow Meters: Accuracy In Cold Fluid Measurement

- Solution For Low Flow And Low Volume Applications: Low Flow Meter In Detail

- Turbine Water Flow Meter: A Versatile And Reliable Choice For Water Flow Measurement

- Pulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

- Guide On Industrial Air Flow Measurement Devices

- Everything You Need To Know About Chemical Flow Meters

- Boat Fuel Flow Meters: Installation Tips and Comparability

- Industrial Refrigerant Flow Meters

- Getting to Know The Propane Flow Meters: Better Monitoring of Propane Utilization

By understanding the principles behind different types of rotameters and their applications, industries can make better choices when selecting flow measurement equipment, ensuring that they meet the specific requirements of their operations.

Sino-Inst not only provides gas rotameters but also various types of liquid rotameters. Optional configurations include 4-20mA signal remote transmission, electronic digital display, explosion-proof, corrosion-resistant, alarm, high-temperature resistance, and other customized parameters.

If you need to purchase gas rotameters or have related technical questions, please feel free to contact our sales engineers!

-1.jpg)