In addition to its potential value in different industries, molasses also provides many benefits to the human body. It helps eliminate problems related to obesity, anemia, depression, acne, and other skin diseases. In addition, molasses is beneficial for bone and hair health. It also keeps the nervous system balanced and accelerates wound healing.

Molasses are the source of fermentable sugars in ethanol manufacturing. Given these applications, accurate molasses flow measurement is essential for precise ingredient control, efficient production, and cost management.

What Is Molasses?

Molasses (or treacle in the UK consumer market) is a general term for concentrated juice from sugarcane or sugarbeet, or raw cane sugar in concentrated solution after varying amounts of sucrose have been removed.

Sugarcane molasses is the major food molasses. Both sugarbeet and sugarcane molasses are used for animal feed and as fermentation sources for ethyl alcohol and other chemicals.

Molasse, a byproduct of sugar production, is a dense, viscous liquid with a dark brown tint. It is rich in sugars and contains a small percentage of water. According to the region, it is known as exhausted honey, poor honey, final honey, residual honey, or simply molasse. Its density ranges from 1.4 to 1.5 g/mL, and its productivity is 40 kg/ton of sugarcane. The ethanol output is 280–230 L/ton of molasse.

Molasses composition depends on variety, age, state of sanity, maturation, planting system, fertilization, and crop treatment. Climate conditions, sugar manufacturing processes, whether the sugarcane was harvested crudely or burned, weather and storage conditions, and other factors are also deciding factors.

Why Accurate Molasses Flow Measurement is Important

- Operational Efficiency

- Cost Control

- Regulatory Compliance

- Process Control

Challenges in Measuring Molasses Flow

These factors necessitate choosing a flow meter specifically designed for viscous liquids like molasses.

Benefits of Accurate Molasses Flow Measurement

- Investing in a reliable molasses flow meter provides several benefits:

- Improved product quality through consistent ingredient ratios.

- Reduced waste and cost savings.

- Enhanced process control and efficiency.

- Compliance with industry regulations.

- Long-term cost-effectiveness due to reduced maintenance and downtime.

Types of Flow Meter for Molasses

1. Oval Gear Flow Meters

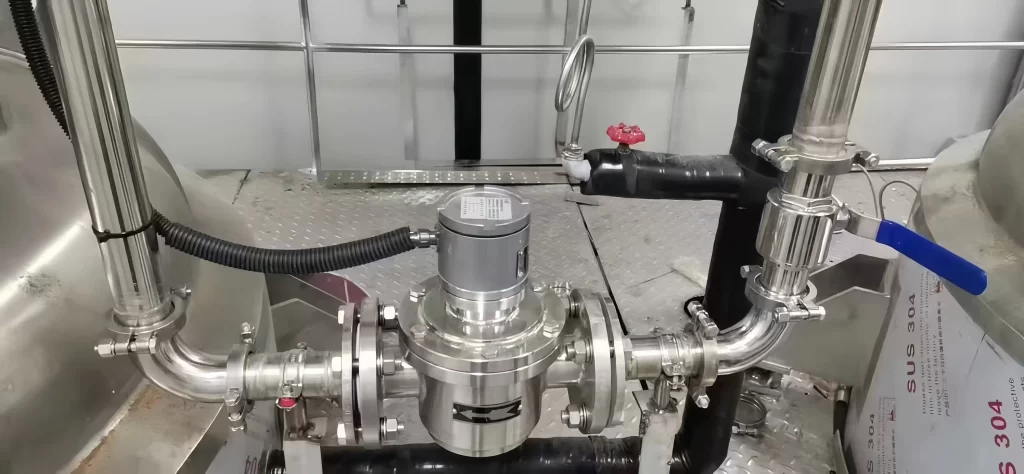

Oval gear meters are a type of PD meter that uses interlocking oval-shaped gears to measure the flow of viscous fluids. The stainless steel oval gear flow meter is one of the best options for measuring viscous fluids like molasses. Can effectively measure molasses flow.

Advantages:

- High accuracy for thick liquids like molasses.

- Minimal pressure drop.

- Easy to maintain.

Limitations:

- It may require frequent cleaning if impurities are present in the molasses.

2. GF Gear Flow Meters

The GF series gear flow meter is another effective choice for measuring molasses flow. It is mainly suitable for measuring conditions such as high viscosity, small flow, high pressure, etc. 304, 316, 316L and other stainless steel materials can be selected.

Advantages:

- High-pressure resistance (1.0-45MPa);

- Low flow can be measured as low as 0.6L/h;

- Can measure various viscous media;

- Wide range ratio (1:100);

- Wide measurement range;

Limitations:

- The media needs to be kept clean to prevent clogging.

- Not suitable for large flow measurements.

3. Coriolis Flow Meters

Liquid mass flow meters, particularly Coriolis mass flow meters, have emerged as reliable tools for measuring molasses. Unlike volumetric flow meters mass flow meters determine flow directly by measuring mass, making them unaffected by density or viscosity changes.

A Coriolis mass flow meter operates by sending fluid through a vibrating tube; the flow rate is calculated based on changes in vibration caused by the Coriolis effect. This provides an accurate measurement of mass flow rate, independent of fluid characteristics like density and viscosity.

Advantages:

- Accuracy and Reliability: With a mass flow meter, accuracy typically falls within ±0.1% to ±0.2% of the reading; ensuring consistent measurement despite molasses’s challenging properties.

- Real-time Density Measurement: Mass flow meters provide real-time density readings, allowing operators to monitor molasses quality continuously. This feature helps identify any composition changes that may affect production.

- No Moving Parts: Coriolis mass flow meters are ideal for molasses since they lack moving parts that could clog or wear out due to the fluid’s high viscosity, making them low-maintenance.

- Temperature Compensation: Since molasses’s viscosity and density vary with temperature, mass flow meters with integrated temperature sensors adjust readings accordingly, ensuring precision across various conditions.

Limitations:

- Compared to other flow meter options, cost is the main concern when using the Coriolis mass flow meter.

Key technical factors for molasses-compatible mass flow meters

Applications of Molasses Flow Meters

- Sugar Industry

- Monitoring molasses flow during extraction and refining processes.

- Ensuring consistent flow in large-scale storage and transfer systems.

- Distilleries

- Measuring precise quantities of molasses for fermentation.

- Maintaining consistency in alcohol production.

- Food Processing

- Accurately dosing molasses in recipes for baked goods, sauces, or confectionery.

- Animal Feed Production

- Monitoring molasses flow during mixing with other feed ingredients.

- Biofuel Production

- Controlling the flow of molasses used in ethanol or biodiesel production.

More Flow Measurement Solutions

- Mechanical & Digital Kerosene Flow Meters

- Understanding Asphalt And Bitumen Flow Meters

- Extreme Temperature Flow Meters: Accurate Flow Measurement In Harsh Environments

- Inline Thermal Mass Flow Meters | Sino-Inst

- Mass Flow Meter Vs Magnetic Flow Meter

- Liquid Mass Flow Meters And Its Significance

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

With options ranging from positive displacement meters to advanced Coriolis flow meters, there’s a solution for every application and budget. By considering factors like viscosity, accuracy, and maintenance requirements, you can select a flow meter that ensures smooth operations and optimal performance.

For expert advice on selecting the best flow meter for your needs, Sino-Inst is always available in the market with the best flow meter solutions. Sino-Inst’s High Viscosity Oval Gear Flow Meter and GF Series Gear Flow Meter with great technical specifications are the best flow measurement options for Molasses. Please feel free to contact our sales engineers!

-1.jpg)