Mass flow meters are not just noteworthy pieces of technology; they have practical applications across various industries. They play a crucial role in ensuring the accuracy of recipe formulations and material balance calculations in industrial process control and are key to financial operations such as billing and custody transfer.

This blog post provides an in-depth look at Liquid mass flow meter technology—from Coriolis to thermal—detailing how these instruments are used to achieve accurate measurements critical for process optimization and commercial transactions.

What is a Liquid Mass Flow Meter?

Liquid mass flow meters are specialized equipment for measuring liquid mass flow rates. Liquid mass flow meters determine the mass of the fluid directly, as opposed to volumetric flow meters, which measure the amount of fluid traveling through a pipe or channel. This measurement is valuable because it remains constant regardless of pressure or temperature changes.

Types of Liquid Mass Flow Meters

Let’s take a closer look at each of these technologies:

1. Coriolis Flow Meters

In a Coriolis meter, the liquid to be measured passes through one or more oscillating tubes; the rate at which mass flows affects the oscillation of the tubes, and from this, both mass flow and density can be determined.

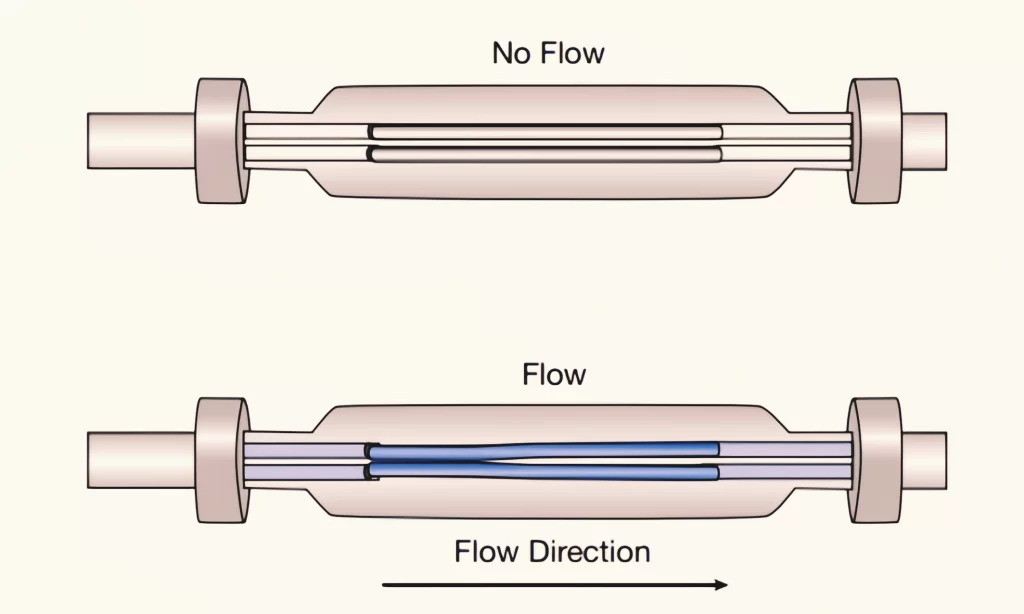

If there is no liquid flowing through the tubes, they simply vibrate toward and away from each other in parallel(Figure 1, top) and the outputs of the upstream and downstream motion sensors are in phase. However, as liquid flows through the tubes, the Coriolis effect causes the downstream side of the loop to slightly lead the upstream side, which creates a slight twist in the loops of tubing (Figure 1, bottom).

The amount of twist (which is exaggerated in the figure for illustration purposes), and hence the phase difference between the outputs of the upstream and downstream pickoff sensors, varies linearly with the rate at which mass is flowing through the tubes. Phase is converted to time, and the time delay is directly proportional to the mass flow rate.

Measuring density: The natural vibration frequency of the tubes is determined by their stiffness and mass. Since the volume of liquid in the tubes is constant, a change in the density of the liquid causes a change in the mass within the tubes. When the mass inside the tubes changes, the natural frequency of the tubes also changes, and this change is detected by the pickoff sensors. The natural frequency is directly related to the density of the liquid inside the tubes.

Although temperature measurement is not necessary to determine mass flow rate, most Coriolis meters include a temperature sensor to compensate for the slight change in the tube stiffness (Young’s modulus) with temperature. Temperature is typically offered as a third output variable, along with flow rate and density.

Advantages:

- High accuracy and precision;

- Direct mass flow measurement;

- Ideal for a wide range of liquids and gases;

- Measures density and temperature alongside mass flow;

Disadvantages:

- Higher initial cost compared to other types;

- Sensitive to installation conditions, requiring proper mounting;

2. Thermal Mass Flow Meters

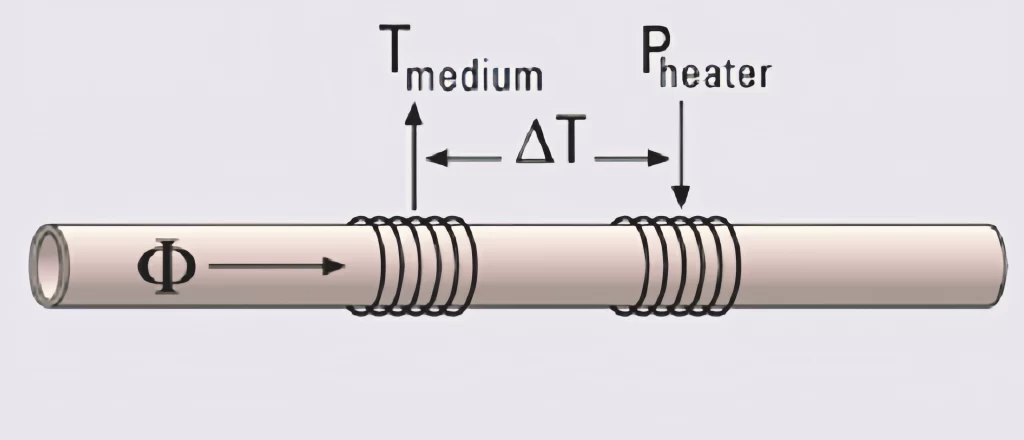

The sensor unit of a thermal mass flow meter consists of two sheath pipe-shaped sensors acting as flow speed sensor and temperature sensors, respectively. The flow speed sensor is controlled (heated) to a specified temperature difference from ambient temperature.

The heat taken away from the flow rate sensor due to the fluid flow is correlated to the mass flow. Therefore, the mass flow rate can be obtained from the amount of power applied to the flow rate sensor to compensate for the removed heat. Thermal mass flow meter features a wide flow range and enables direct measurement of mass flow rate without compensating temperature and pressure.

How does a thermal mass flow sensor work for liquids?

A thermal mass flow sensor uses the thermal properties of liquids to measure their mass flow rate. To this end, as can be seen in Figure 2, heat is introduced into the streaming liquid by a heater, and the (temperature) sensor measures how much heat is absorbed by the liquid. In these thermal mass flow meters for liquids, the heater, as well as the sensor, are built around a stainless-steel main flow channel tube with no moving parts or obstructions inside the tube.

Advantages:

- Direct measurement of mass flow rate;

- Can be used for a wide range of liquids;

- Simple design and cost-effective for certain applications;

Disadvantages:

- Can be less accurate with highly variable fluids;

- Limited to low-flow applications;

Applications of Liquid Mass Flow Meters

Advantages of Liquid Mass Flow Meters

- Accuracy

- Process optimization

- Assuring product quality

- Independence from Fluid Properties

- Low Maintenance

- Real-Time Monitoring

- Boosting energy efficiency

- Ensuring safety and regulatory compliance

Selecting the Right Liquid Mass Flow Meter

- Fluid Characteristics: Is the fluid conductive, viscous, or prone to temperature fluctuations? Coriolis meters excel in measuring a wide variety of fluids, including those with varying densities.

- Accuracy Requirements: Coriolis flow meters are ideal for high-accuracy applications, while thermal mass flow meters can be more suitable for low-cost, low-flow situations.

- Installation Conditions: Consider pipe size, pressure conditions, and potential for vibration. The installation environment can impact the choice of flow meter technology.

More Flow Measurement Solutions

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

Finally, we looked at the fundamental aspects of Liquid mass flow meters and their significance in accurately measuring flow. In industrial process control, mass flow meters play a key role in managing and monitoring material flow. It guarantees that flow measurements are accurate and per the process requirements.

Hopefully, this kind of discussion will help Businesses make informed decisions about the right technology for their needs—ultimately leading to better products, optimized processes, and improved bottom lines. Sino-Inst is doing a fabulous job in the worldwide market with a range of liquid mass flow meter solutions. If you need to purchase liquid mass flow meter, or have related technical questions, please feel free to contact us.

-1.jpg)