Inline thermal mass flow meters install the pipeline flow meter body in the pipeline for a long time. A thermal gas mass flow meter is a flow meter designed based on the principle of thermal diffusion or heat conduction to measure the mass flow of gas. There are online and insertion structures.

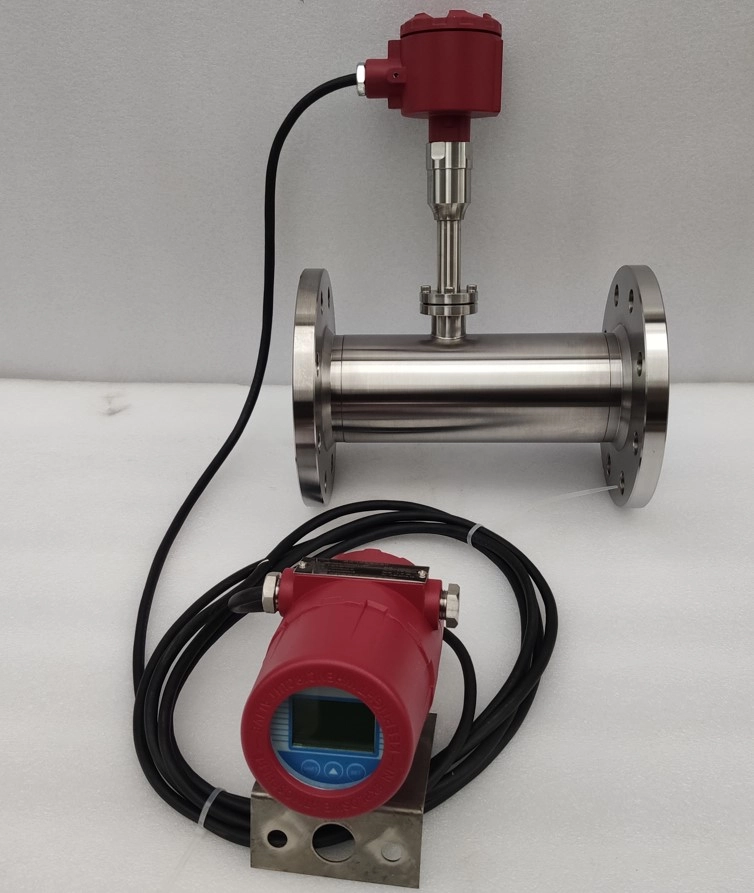

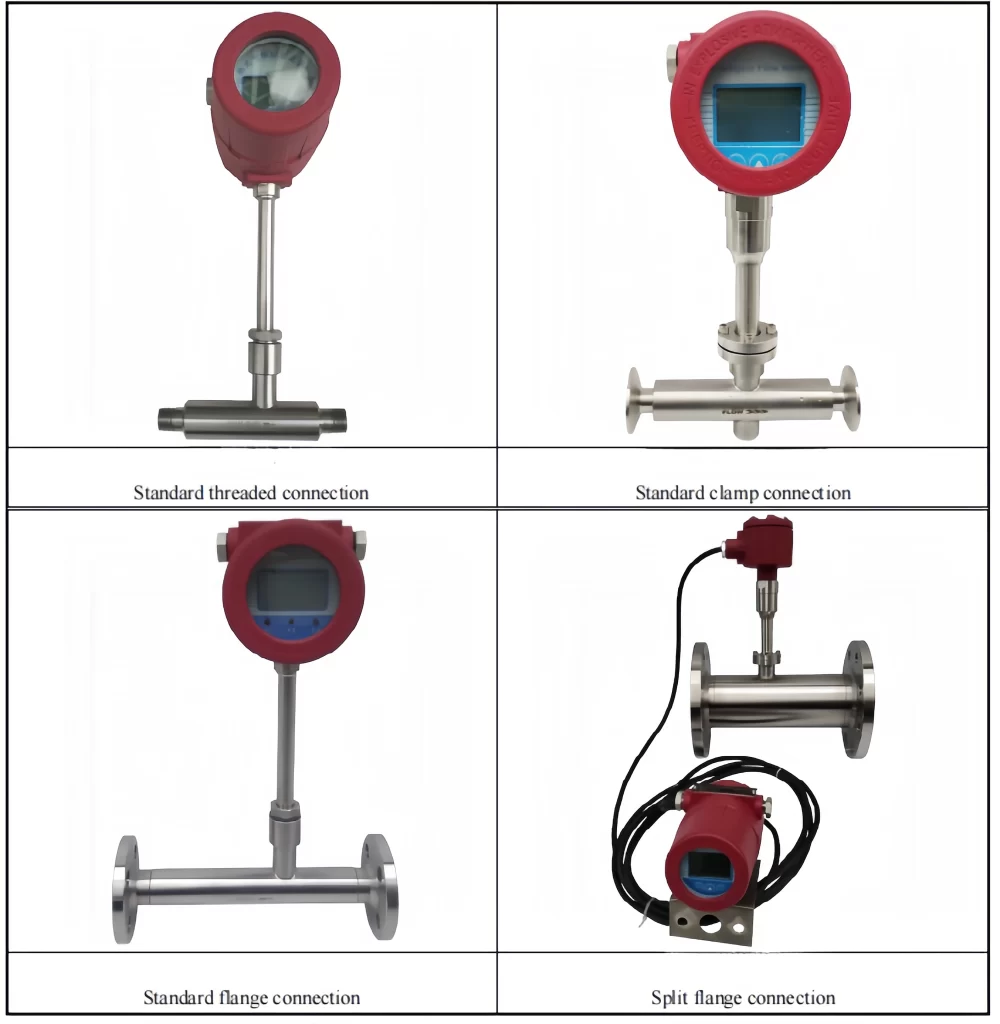

Inline thermal mass flow meters can be customized into threaded installation, clamp installation, flange installation, one-piece structure, split structure, etc.

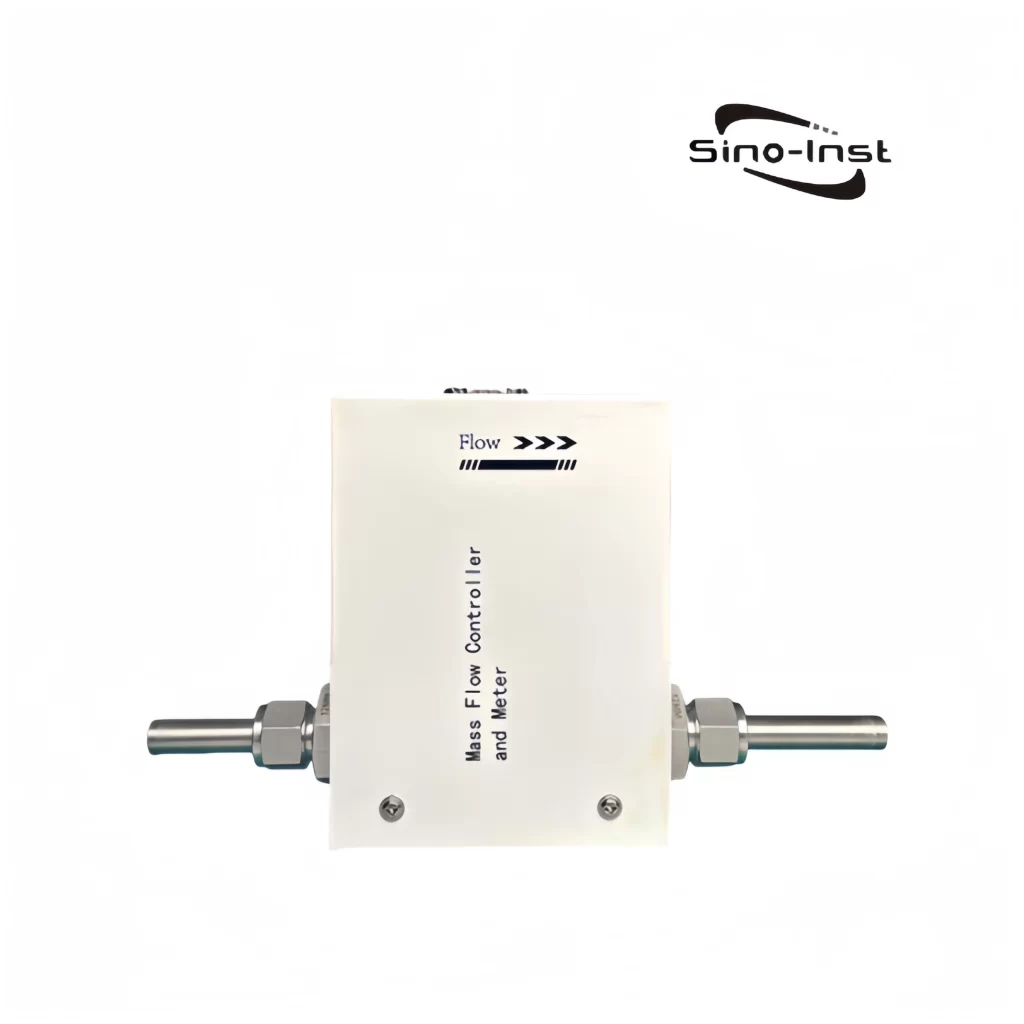

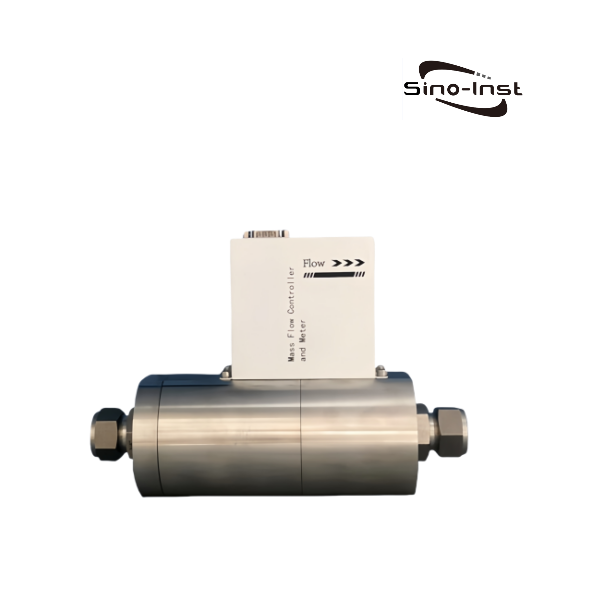

Featured Inline Thermal Mass Flow Meters

Benefits of Inline Mass Flow Meters

- The setting of different gas coefficients;

- Clearing of display zero;

- Calibration of output analog quantity;

- Correction of multi-point nonlinear curve;

- Wide range ratio greater than 100:1;

- The measurement results are not affected by fluid properties (such as temperature, pressure, humidity, composition, etc.);

- The instrument can be set on-site;

- Packaged sensor with near-zero pressure loss;

- Insensitive to vibration;

- Small straight pipe section requirements;

- The measured value is independent of pressure, true mass flow detection;

- Adopt an expert algorithm to achieve high accuracy and stability of the instrument;

- Response time of less than one second;

- LCD display with instantaneous accumulation dual display, no need to switch;

Featured Applications

Thermal gas mass flowmeters are widely used in many fields, including but not limited to:

In addition, it can also be used for:

- Measurement of oxygen, nitrogen, hydrogen, chlorine, and multi-component gases;

- Measurement of blast furnace gas and coke oven gas;

- Measurement of flue gas;

- Measurement of aeration and chlorine in biogas and water treatment;

- Measurement of compressed air;

- Measurement of gas flow such as natural gas, liquefied gas, flare gas, etc.;

- Measurement of primary and secondary airflow of the blast furnace in the power plant;

- Measurement of flow of ventilation or exhaust system in mine;

- Measurement of airflow in the as combustion process;

- Measurement of flue gas flow (speed) discharged from the chimney (CEMS);

- Measurement of flue gas flow in calcining furnace;

- Measurement of gas flow in cement, cigarette, and glass factory production process;

- Measurement of gas flow in solvent recovery system;

- Measurement of gas flow in semiconductor chip manufacturing process;

- Measurement of carbon dioxide gas flow in the beer production process;

- Measurement of gas flow (speed) in heating, ventilation, and air conditioning system;

- Measurement of combustion gas flow in coal-fired boiler, etc.

Not applicable: Gas containing water vapor. Liquid, solid.

Inline Thermal Mass Flow Meters Working Principle

Thermal gas mass flowmeters use the principle of thermal diffusion. Thermal diffusion technology is a technology with excellent performance and high reliability under harsh conditions. Its typical sensing elements include two thermal resistors (platinum RTDs). One is a velocity sensor and the other is a temperature sensor that automatically compensates for changes in gas temperature.

When the two RTDs are placed in the medium, the velocity sensor is heated to a constant temperature difference above the ambient temperature, and the other temperature sensor is used to sense the medium temperature. The mass flow of gas flowing through the velocity sensor is calculated by the amount of heat transferred by the sensing element. As the gas velocity increases, the amount of heat transferred to the medium by the sensor increases.

The gas mass flow rate is determined by measuring the temperature difference (△T) between the heater and the thermometer, and the temperature difference is proportional to the mass flow rate of the gas.

Based on the temperature difference between the heater and the temperature sensor and the known heater characteristics and gas properties, the mass flow rate of the gas can be calculated using mathematical relationships such as King’s law of thermal effect (such as P/△T=K1+K2 f(Q)K3, where P is the heating power, △T is the temperature difference, Q is the mass flow rate, and K1, K2, and K3 are constants related to the physical properties of the gas).

How accurate is a thermal mass flow meter?

The accuracy of the inline type of thermal mass flow meter is ±1.0~1.5%. The insertion type has an accuracy of ±1.5~2.5%. For gas flow measurement, this is already a very good accuracy. And it can meet the requirements of most users.

Customer Cases

Sino-Inst supports parameter customization of Inline Thermal Mass Flow Meters. The following are the parameters of two cases:

- Inline thermal mass flowmeter

DN20mm,

Measure nitrogen

AC220V/DC24V dual power supply

Output 4~20mA, with RS485 communication

LCD displays instantaneous flow and cumulative total

Main body material 304 stainless steel

R3/4″ thread installation

Flow range 1.1~110Nm3/h

Accuracy 1.5%

Temperature resistance 100℃

Pressure resistance 4Mpa

- Inline thermal gas mass flowmeter

DN100mm

Measure nitrogen

DC24V/AC220V dual power supply

Output 4~20mA with RS485 communication

LCD display instantaneous flow and cumulative total

Main body material 304 JIS 16K RF Japanese standard flange connection

Split type

With 20m cable

Measuring range 28~2800Nm3/h

Temperature resistance 100℃

Pressure resistance 1.6Mpa

More Gas Flow Measurement Solutions

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- Techniques, Importance, and Challenges of Natural Gas Flow Measurement

- DP Transmitter for Flow Measurement

- Guide To Vortex Flow Meters For Steam Applications: Steam Vortex Flow Meter In detail

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases

Inline Thermal Mass Flow Meters require a section of the pipeline to be cut off before installation. They are suitable for process control areas where accurate measurement is required and the pipeline diameter is small.

There are many process gas flow measurements, such as biogas or exhaust gas, that require very low flow rates. This can pose a challenge to old traditional flow measurement technologies such as turbines, differential pressure, vortex, ultrasonic or positive displacement. These technologies only measure volume flow and require additional instruments to determine mass flow.

Thermal mass flow meters measure mass directly without considering changes in process temperature, pressure and density like volume flow meters. Sino-Inst’s Inline Thermal Mass Flow Meters are most popular in measuring air, natural gas and biogas, argon, helium, propane, and any industrial gas measurement applications.

If you need to purchase Inline Thermal Mass Flow Meters, or have related technical questions, please feel free to contact us.

-1.jpg)