To begin with: Vortex Flow Meters for Steam Applications

The requirement for high-fidelity and trustworthy flow measurement has become pivotal across various industries, especially in applications involving steam. Steam is widely used in industries such as power generation, chemical processing, and manufacturing. Where the need to measure the flow of steam accurately is hypercritical for efficiency, safety, and cost control. Among the many flow meter technologies available today, the ‘steam vortex flow meter’ stands out as a favorite and highly effective alternative.

In this blog, we will dig into the principles of “vortex flow meters for steam applications”, talk about their benefits, and explore why they are especially well-fit for steam flow measurement.

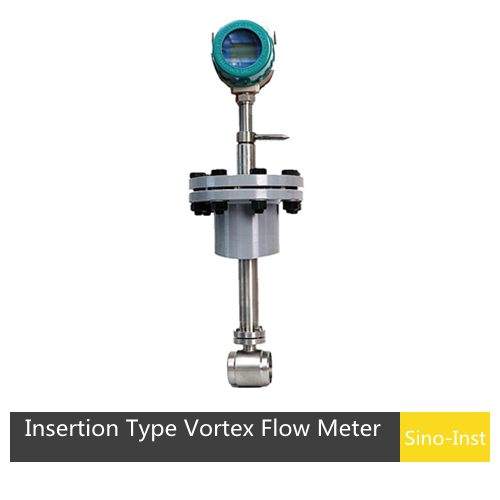

Featured Steam Vortex Flow Meters

Unveiling Vortex Flow Meters: Let’s know about it

A Vortex flow meter is a type of volumetric flow meter that makes use of a natural phenomenon that occurs when a liquid flows around a bluff object. Vortex flow meters operate under the vortex shedding principle, where vortices (or eddies) are shed alternately downstream of the object. The frequency of the vortex shedding is directly proportional to the velocity of the liquid flowing through the meter.

Vortex flow meters are best suited for flow measurements where the introduction of moving parts presents problems. Sensitivity to variations in the process conditions are low and, with no moving parts, relatively low wear compared to other types of flow meters.

Working Principle:

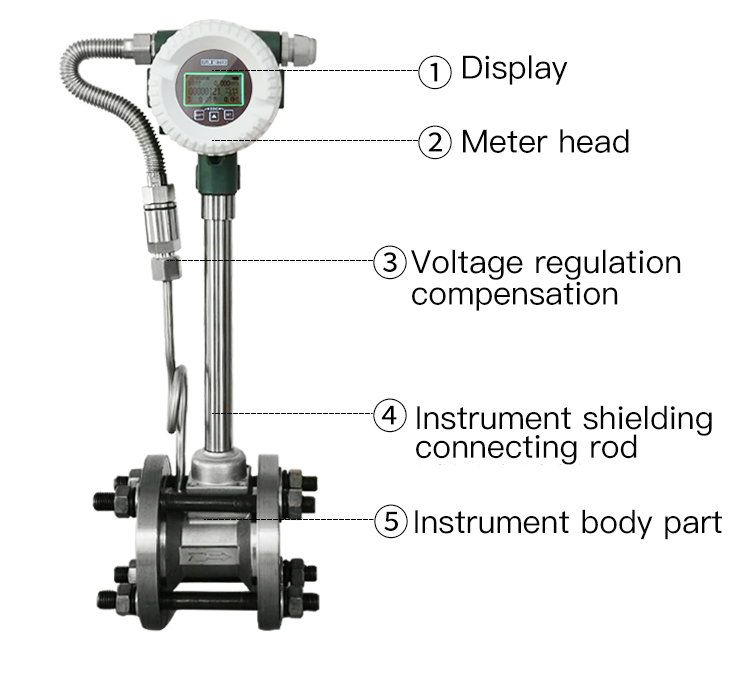

The vortex flowmeter measures volume flow based on the Karman vortex principle. The vortex flowmeter is composed of a vortex generator, a detection probe, and corresponding electronic circuits.

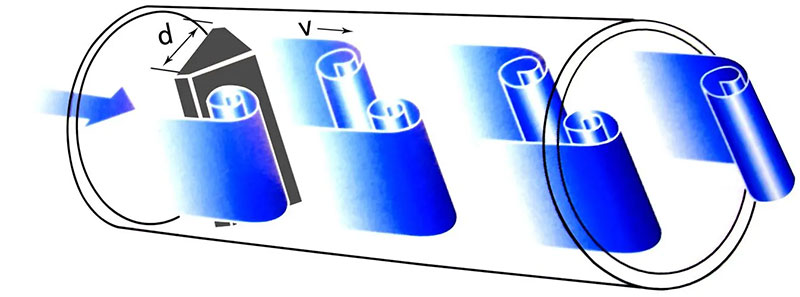

A non-streamlined vortex-generating body (blocking member) is provided in the fluid. Then two rows of regular vortices are alternately generated from both sides of the vortex generator, and this vortex becomes the Karman vortex street. As shown below:

The vortex rows are arranged asymmetrically downstream of the vortex generator. Suppose the frequency of vortex generation is f, the average velocity of the incoming flow of the measured medium is V, the width of the flow-facing surface of the generating body is d, and the diameter of the surface body is D. According to the Karman vortex street principle, there is the following relationship:

f=StV/d

In the formula:

F – Karman vortex frequency generated on one side of the generating body.

St-Strohal number (dimensionless number)

V-average flow velocity of fluid

d-width of vortex generator

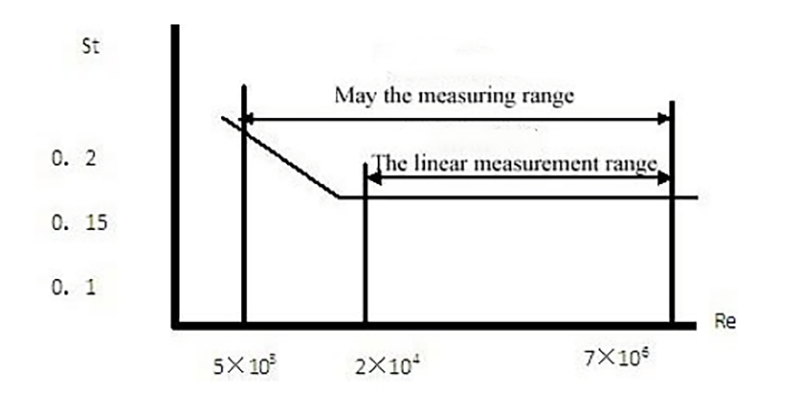

It can be seen that the instantaneous flow rate can be calculated by measuring the Karman vortex separation frequency. Among them, Strohal number (St) is a dimensionless unknown number. The following figure shows the relationship between Strohal number (St) and Reynolds number (Re).

In the curve table, the straight part of St=0.17. The release frequency of vortex is proportional to the flow speed, which is the measurement range of the vortex flow sensor. As long as the frequency f is detected, the flow rate of the fluid in the tube can be found. The volumetric flow rate is determined from the flow velocity V. The ratio of the measured pulse number to the volume flow rate is called the instrument constant K.

K=N/Q(1/m³)

In the formula:

K=instrument constant (1/m³)

N=Number of pulses

Q=volume flow

Central Components of a Vortex Flow Meter:

- Bluff body: The object that causes vortices to form in the fluid.

- Sensor: Detects the vortices and converts them into electrical signals.

- Electronics: Processes the sensor signals and calculates the flow rate.

Vortex flow meters are versatile and can be used to measure the flow of various types of fluids, but they are particularly well-suited for applications involving steam.

Features that make Vortex Flow Meters Perfect for Steam Applications

Steam, whether it’s saturated or superheated, presents several situations for accurate flow measurement. It has high temperatures, varying pressure levels, and unique fluid properties that require a robust and reliable flow meter. The steam vortex flow meter excels in addressing these challenges.

Here’s why vortex flow meters are particularly advantageous for steam applications:

1. Robust Design

2. Wide Range of Steam Applications

Saturated steam: Steam at its boiling point and in equilibrium with water.

Superheated steam: Steam at a temperature above its boiling point.

Each type of steam has different flow characteristics, but vortex flow meters can handle both with ease, providing accurate and reliable measurements.

3. Direct Mass Flow Measurement

4. High Accuracy and Stability

Operating Mechanism of Steam Vortex Flow Meters

a. Vortex Shedding Phenomenon

In fluid dynamics, vortex shedding is an oscillating flow that takes place when a fluid such as air or water flows past a bluff (as opposed to streamlined) body at certain velocities, depending on the size and shape of the body.

b. Calculating Mass Flow for Steam

In steam applications, simply measuring the volumetric flow is not sufficient, as the density of steam changes with pressure and temperature. To accurately measure the mass flow, vortex flow meters are often equipped with integrated temperature and pressure sensors. These sensors provide real-time data on the steam’s operating conditions, allowing the meter to calculate the mass flow using the following relationship:

Mass Flow =Volumetric Flow*Density

Since steam density is a function of both temperature and pressure, the integrated sensors ensure that the mass flow is accurately calculated, compensating for any changes in these parameters.

c. Rectification for Saturated and Superheated Steam

Vortex flow meters can be used for both saturated and superheated steam.

For saturated steam, the temperature and pressure are in equilibrium, so the steam’s density can be determined based on a standard steam table.

For superheated steam, yet, the temperature is higher than the boiling point, requiring more sophisticated compensation methods.

Vortex flow meters deal with this compensation automatically, ensuring accurate mass flow measurement regardless of the steam type.

Read more about: What Is Temperature Compensation and Pressure Compensation for Flow Meters?

Utilization of Vortex Flow Meters in Steam Systems

Vortex flow meters are widely used in industries where steam plays a crucial role in energy transfer, heating, or mechanical work. Some popular steam applications where vortex flow meters are indispensable include:

a. Power Generation

b. Heating Systems and Boilers

c. HVAC Systems

d. Steam Distribution Networks

Benefits of Using Vortex Flow Meters for Steam Applications:

To sum up, ‘vortex flow meters for steam applications’ offer various fundamental advantages:

- Accuracy

- Wide Range

- Durability

- Direct Mass Flow

- Low Maintenance

More Featured Steam and Gas Flow Measurement Solutions

- Featured Gas Turbine Flow Meter for Natural Gas and Other Gases

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Electronic Flow Meters-Digital Display

Stopping point

Steam plays a crucial role in numerous industries, and accurate steam flow measurement is indispensable for optimizing performance, reducing energy consumption, and ascertain safe operation. ‘Steam vortex flow meters’ have appeared as a time-tested and faithful solution for measuring steam flow, offering robust operation in difficult environments.

By leveraging the vortex shedding phenomenon, these meters provide precise mass flow measurements for both saturated and superheated steam, making them a versatile tool for a wide range of steam applications. Their low maintenance requirements, durability, and ability to compensate for temperature and pressure changes make them a preferred choice for industries where steam is a critical resource.

Whether you’re involved in power generation, industrial heating, or steam distribution, investing in a vortex flow meter for steam applications can help you achieve better process control, efficiency, and cost savings.

-1.jpg)