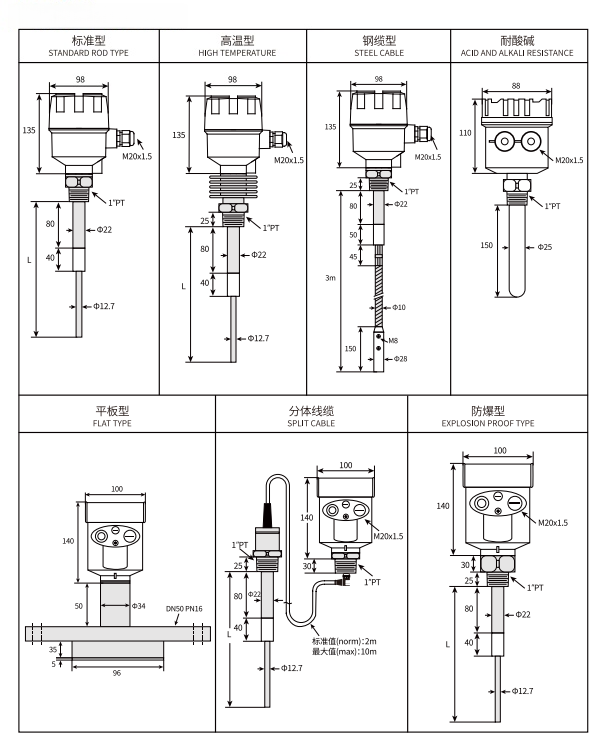

Electrostatic capacitive level switches are suitable for measuring various material levels. Due to their simple construction, utilizing the resonant circuit principle and equipped with a highly reliable sensitivity adjustment capacitor, the sensitivity is continuously adjustable. They are widely used in food and feed, chemical, metallurgical, and power industries. They can be used in high-temperature, high-pressure, strong acid, and strong alkali environments.

Features

Technical Parameters

| Power Supply Voltage | 220VAC, 24VDC |

| Signal Output | Relay 5A/250VAC SPDT |

| Operating Temperature | -20~120℃ (High Temp 235℃) |

| Operating Pressure | Atmospheric pressure (High pressure 2.5MPa) |

| Delay Time | 0~30s adjustable |

| Sensitivity | 0.5pf ~ 750pf |

| Electrical Interface | M20x1.5 |

| Probe Material | SUS304 + PTFE, customizable to 316L or PTFE coating |

| Connection Method | Thread G1“, 1” PT, customizable with chuck or flange |

| Protection Rating | IP65 |

| Junction Box Material | Aluminum alloy with baked paint finish |

Electrostatic Capacitive Level Switch Working Principle

A capacitive level switch uses the switch’s probe (sensing electrode) and the tank wall (grounding electrode) as the two plates of a capacitor. When the measured material accumulates and comes into contact with the electrodes, the capacitance between the electrodes and the metal tank wall or grounding electrode increases. When the material’s accumulation level decreases and it no longer contacts the electrodes, the capacitance decreases, and the contact signal returns to its initial state.

The level switch’s analysis and processing unit detects the magnitude of this change. When this change reaches the switch’s set value, it switches the switch signal output for control purposes, thus reflecting the level of the measured medium or material interface.

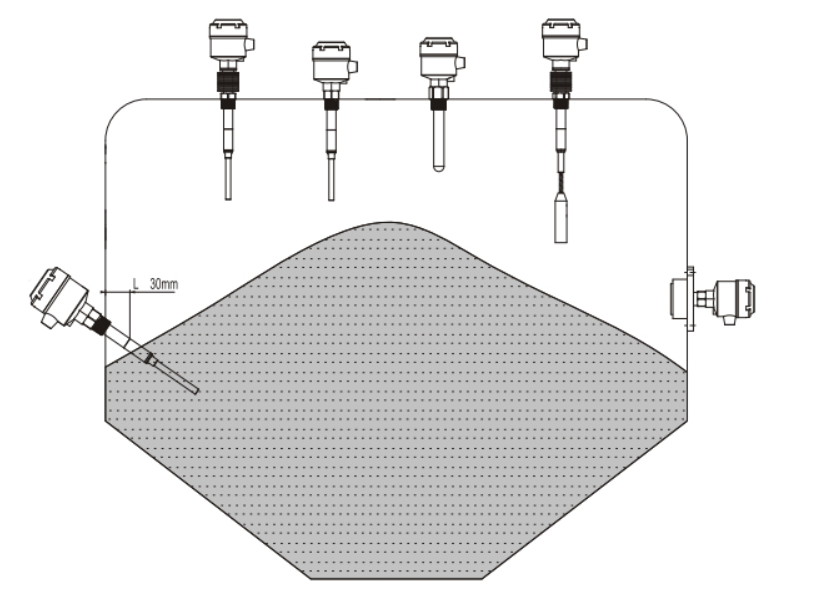

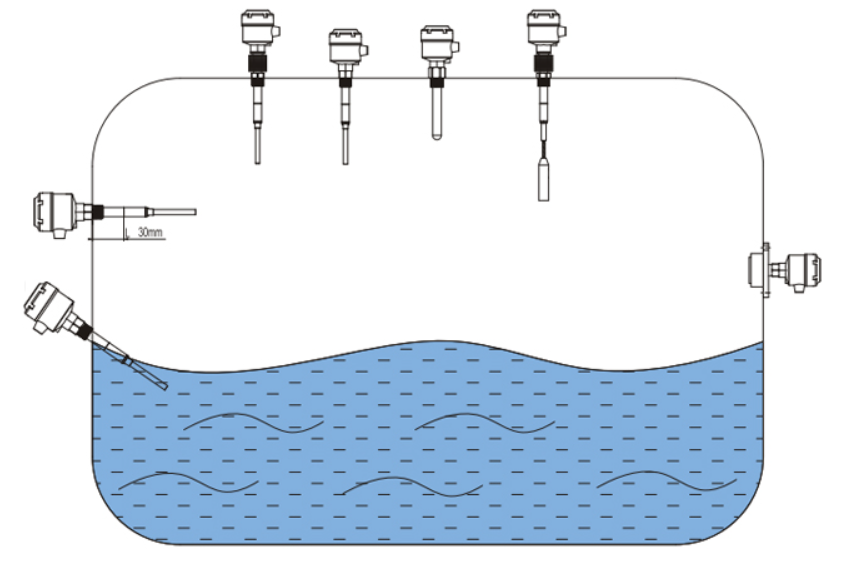

Applications

- Liquids: Various solvents, fuels, water, pure water, etc.;

- Mixed media: Factory wastewater, wastewater, domestic sewage, rainwater, etc.;

- Interfaces: Oil-water interfaces, water and sediments in water, bubbles, and laundry detergent, etc.

- Powders: Dust, sand, flour, sugar, lime powder, cement, etc.;

- Granular: Feed, medicine, plastic particles, etc.;

- Lumpy: Coal, gravel, ore, etc.

Electrostatic Capacitive Level Switch Wiring and Debugging

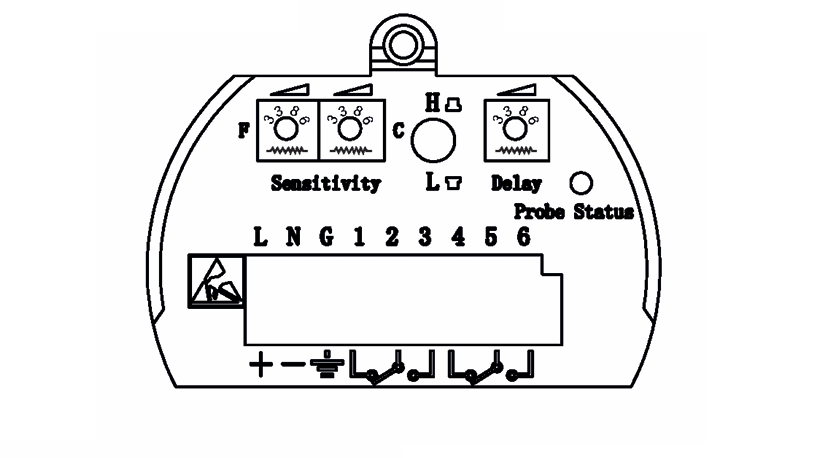

(1) Connect the power supply, ensuring the voltage is correct; For 220VAC, L (live wire), (neutral wire), G (ground wire, ensure proper grounding); For 24VDC, + (positive), – (negative):

(2) Sensitivity is the sensitivity adjuster. C is for coarse adjustment, F for fine adjustment. Clockwise increases sensitivity, counterclockwise decreases sensitivity;

(3) H is for high-level output, L is for low-level output, the relay switch state is reversed.

(4) Probe Status is the status indicator light, green indicates power on, red indicates state switching.

(5) Delay: Delay adjustment, adjustable from 0.2-50 seconds. Used to adjust the delay time of the relay switch output. Delay is disabled by default (rotate counterclockwise to the end).

(6) First rotate F to the middle position, then adjust C clockwise or counterclockwise, slowly rotating to the critical point. First rotate clockwise to the red light, then counterclockwise to the green light, repeating 1-2 times. Finally, stop at the green light position; this position is called the critical point.

(7) Adjust C and F according to different media to achieve the desired state.

Capacitive level switch vs. RF admittance level switch

| Items | Capacitive level switches: | RF admittance level switch |

| Measurement Accuracy | Lower accuracy, highly affected by dielectric constant | High accuracy, effectively eliminating interference from factors such as material buildup and conductivity. |

| Anti-material Adhesion | Poor performance, easily affected by material buildup | Strong performance, shielding technology prevents material buildup interference. |

| Applicable Media | Suitable for dry or low-viscosity media, prone to failure under complex conditions | Suitable for various media including liquids, solids, and slurries. |

| Installation Requirements | Relatively simple installation, but the probe and container wall must be in direct contact with the media | Installation is slightly complex, but highly adaptable. |

| Interference Resistance | Poor performance, easily affected by static electricity, temperature and humidity changes, etc. | Excellent performance; shielding and compensation functions make it suitable for harsh environments. |

| Maintenance Requirements | High maintenance requirements, frequent cleaning of material buildup is necessary | Low maintenance; shielding technology reduces cleaning requirements. |

| Cost | Low price, economical | Higher performance, but superior overall performance and high cost-effectiveness in the long run. |

More Level Measurement and Control Solutions

Case: Non-Contact Material Level Measurement – Radar Level meter

What are Capacitive Level Sensors?

Choosing the Right Level Switch for Industrial Applications: A Complete Guide

Radar Gauge for Level Measurement

GWR Type Level Transmitter: An All-inclusive Guide

Magnetic Level Measurement: Indicators,Transmitters, Switches Or Sensors

Different Solutions for Fluid Level Measurement

Single Point – Multi-Point Float Level Switches | Simple but Effective

Sino-Inst’s capacitive level switches are reliable and inexpensive. They can control the level of lumpy, granular, powdery, and liquid materials in silos, or provide upper and lower limit alarms. Suitable for high-temperature, high-pressure, highly corrosive, dusty, and ultrafine particle environments. Widely used in metallurgy, petroleum, chemical, light industry, coal, cement, and grain industries.

We support customization of level gauges and level switches. If you need level measurement and control, please feel free to contact our sales engineers!

Electrostatic Capacitive Level Switch - Sino-Inst

Electrostatic capacitive level switches are suitable for measuring various material levels. Due to their simple construction, utilizing the resonant circuit principle and equipped with a highly reliable sensitivity adjustment capacitor, the sensitivity is continuously adjustable. They are widely used in food and feed, chemical, metallurgical, and power industries. They can be used in high-temperature, high-pressure, strong acid, and strong alkali environments.

Product SKU: Electrostatic Capacitive Level Switch

Product Brand: Sino-Inst

Product In-Stock: InStock

-1.jpg)