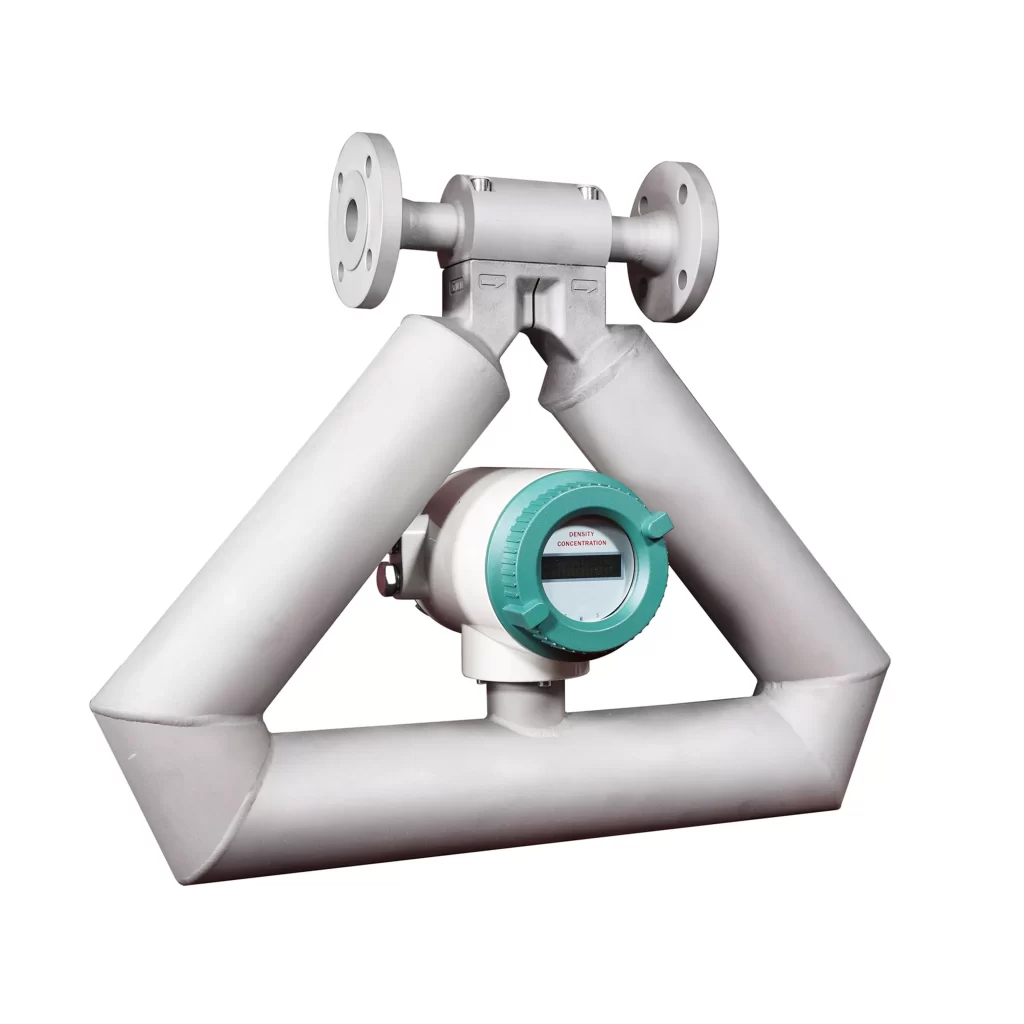

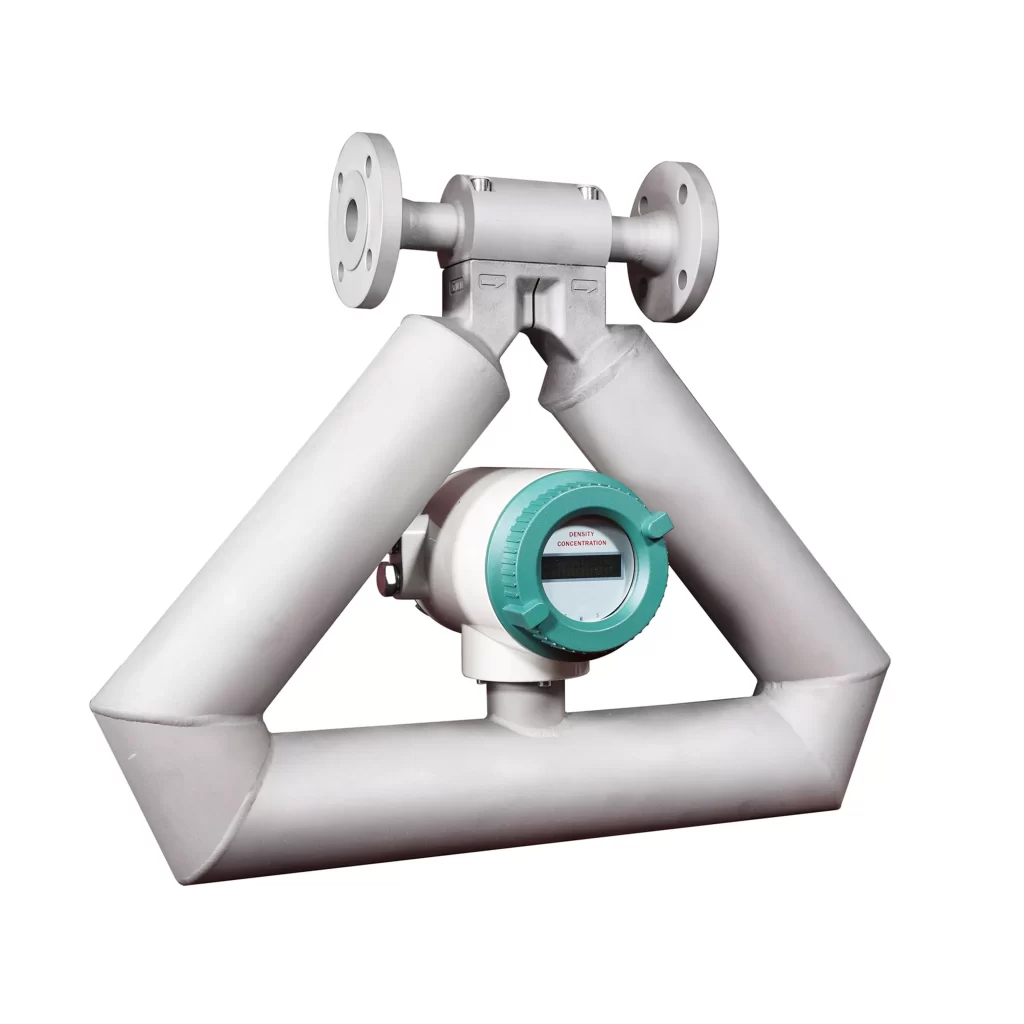

The Coriolis vibration density meter/concentration meter utilizes the relationship between the Coriolis force and the density of a liquid to measure its density. The concentration value at 20°C is then obtained using a density-concentration relationship table.

This principle offers high stability, high accuracy, and excellent long-term stability, eliminating sensor drift. It is widely used in oil refining and blending, sugar production, vegetable oil and beverage processing, papermaking, measuring weak acid and alkali solutions in the chemical industry, and in the wine, salt, and printing and dyeing industries.

Benefits

- Substance Identification and Analysis:

The Coriolis Vibration Density Meter can be used to identify and analyze the composition and properties of substances. Different substances have different densities; by measuring the density of a substance, its composition and purity can be determined. In industrial production, the Coriolis density meter helps to test the quality of raw materials and ensure that the substances used meet requirements.

- Concentration Control and Adjustment:

In some industrial processes, it is necessary to control and adjust the concentration of solutions or mixtures. The Coriolis Vibration Density Meter can determine the concentration of a liquid or solution by measuring its density. By monitoring changes in density, industrial producers can adjust and control the concentration of the solution in real time to ensure that the product meets the prescribed standards.

- Quality Inspection and Quality Control:

The Coriolis Vibration Density Meter plays a crucial role in quality inspection and quality control. By measuring the density of a product, its physical properties and quality characteristics can be assessed. Changes in density may indicate the presence of impurities or substandard components in the product. The Coriolis Vibration Density Meter helps industrial producers conduct rapid and accurate quality inspections to ensure product consistency and compliance.

- Fluid Flow Measurement:

Density meters can be used in conjunction with flow meters to measure fluid flow rate. By measuring the fluid’s density and velocity, accurate flow rates can be calculated. This is crucial for fluid control and flow monitoring in industrial processes such as chemical and petroleum industries.

- Raw Material Selection and Formulation Optimization:

Coriolis Vibration Density Meters help industrial producers select suitable raw materials and optimize formulations. Different raw materials have different densities; by measuring density, the quality and suitability of raw materials can be assessed. Furthermore, by adjusting the proportions and formulations of raw materials, the performance and characteristics of the product can be optimized.

Technical Specifications

| Accuracy | ±0.001g/cc | ±1.0kg/m3 | |

| Measuring range | 0~3g/cc | 0~3000kg/m3 | 0~187.4 lb/ft3 |

| Repeatability | ±0.001g/c | ±0.1kg/m3 | ±0.006lb/ft3 |

| Process temperature effect (corrected) | ±0.001%g/cc) | ±0.1kg/m3 | (per °C) |

| Process pressure effects (corrected) | negligible | ||

| (1) The above accuracy applies to the calibration range 0.6 – 1.25g/cc (600 – 1250 kg/m3). | |||

| (2) The viscosity of the liquid can reach up to 2000cP. | |||

| (3) Temperature effect refers to the maximum measurement deviation caused by the process fluid temperature deviating from the factory calibration temperature. | |||

| (4) Pressure effect is defined as: the change in sensor flow and density sensitivity caused by the deviation of process pressure from the calibrated pressure. | |||

| process temperature | -10℃~+60℃ |

| ambient temperature | -10℃~+85℃ |

| temperature coefficient | 0.1kg/m3/℃ (after correction) |

| Built-in temperature sensor | PT100 |

| Wetted parts | Stainless steel, 316L, PTFE |

| Shell | IP65, aluminum alloy |

| Maximum working pressure | 10MPa |

| Test pressure | Tested at 1.5 times maximum working pressure |

| Tested at 1.5 times the maximum working pressure | |

| Process connection type | flange |

| Tri-Clover (TC) Clamp | |

| Thread | |

| Explosion-proof certification | Exd IIB T6 Gb |

| Power requirements | 24VDC,50mA |

| output | Four-wire system, 4-20mA |

| Viscosity requirements | 0-20000cP |

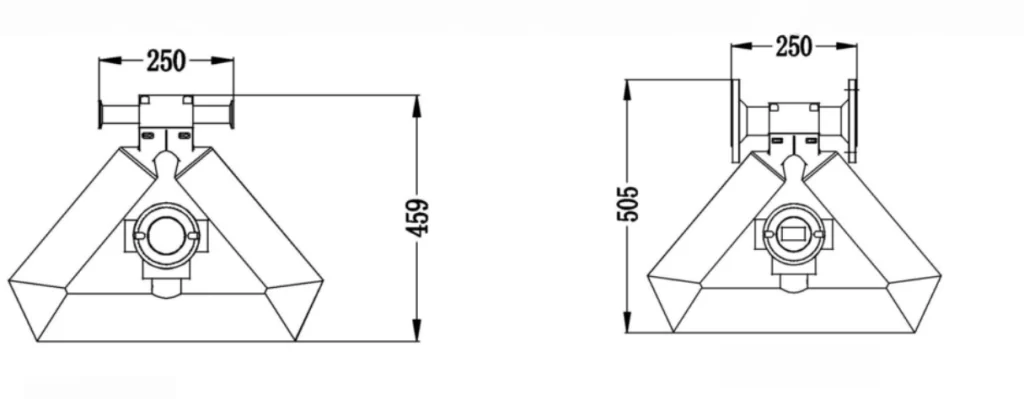

Installation Guide

Due to the requirements of the process flow, this equipment is often installed in harsh working conditions. To minimize the severity of the working conditions, it should be installed in a location with minimal impact and vibration. Furthermore, ensure the liquid level in the pipeline is full to minimize air bubbles. Only by fully considering the specific conditions of the site can its expected accuracy be achieved.

The following points should be noted during installation:

The product must be installed in a location suitable for easy operation. Installation should be appropriate for different working conditions. There are several main methods, and incorrect installation will affect measurement errors.

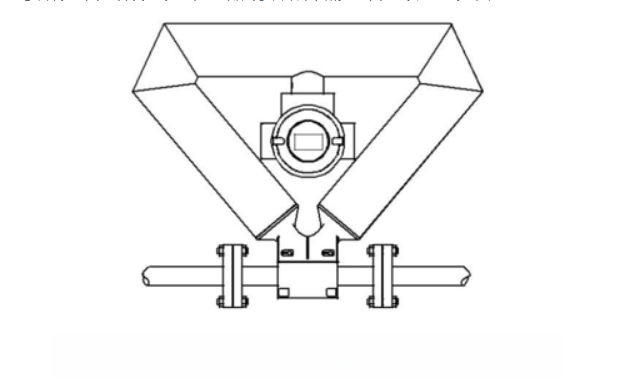

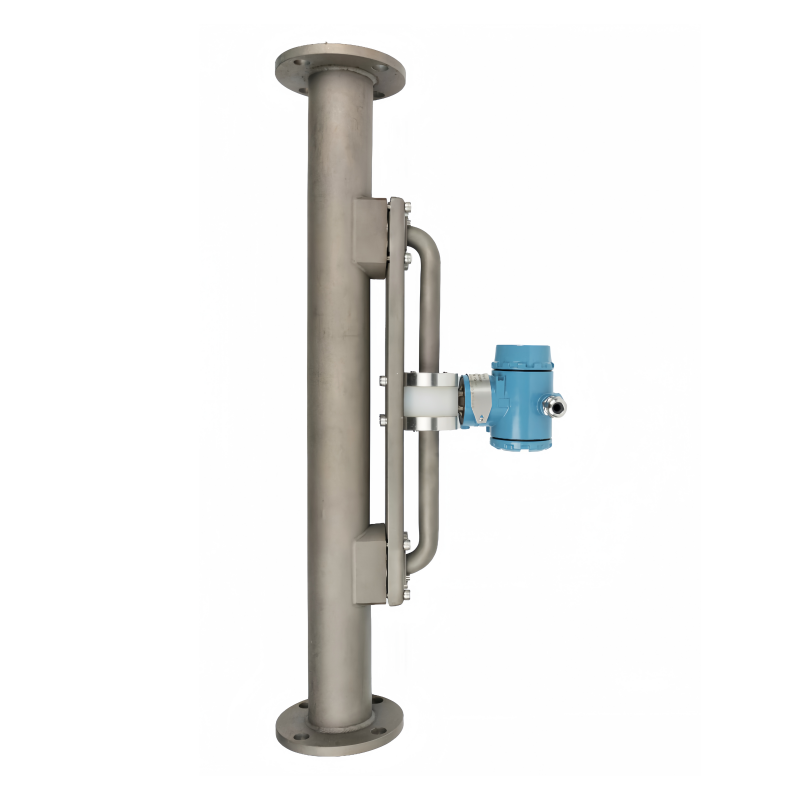

Installed on the upper side of horizontal pipes, suitable for unclean liquids, and can prevent sedimentation.

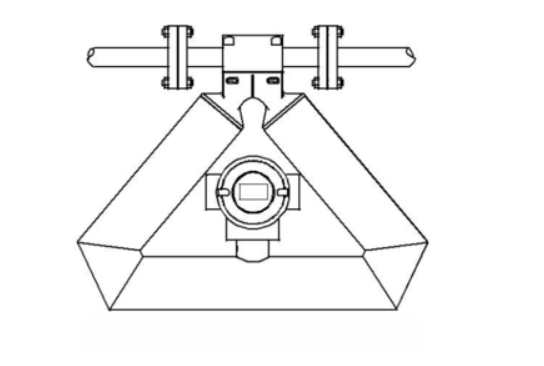

Installed on the upper side of horizontal pipes, suitable for unclean liquids, and can prevent sedimentation. Installed on the underside of horizontal pipes, suitable for pure liquids.

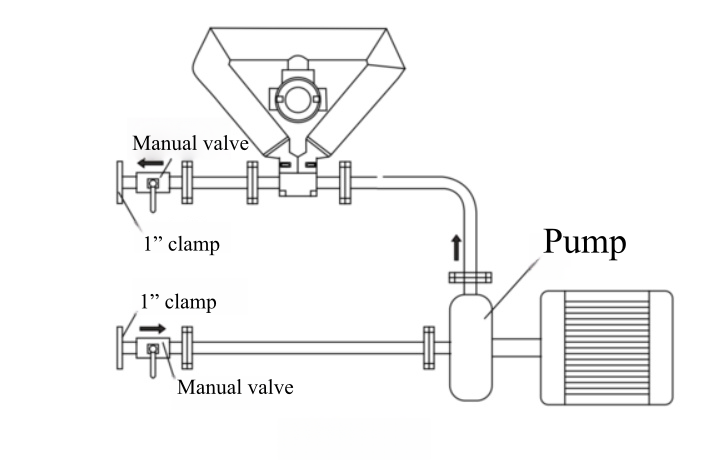

Installed on the underside of horizontal pipes, suitable for pure liquids. Installation with the Pump

Installation with the Pump Vertical pipe installation is suitable for situations where vertical pipes need to be installed.

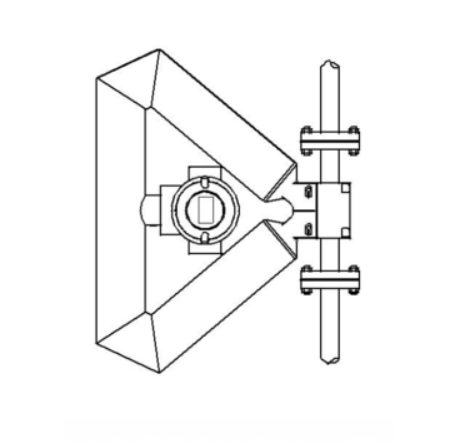

Vertical pipe installation is suitable for situations where vertical pipes need to be installed. Horizontal pipes are installed on the side, which is suitable for liquids with a lot of bubbles and prevents residual bubbles.

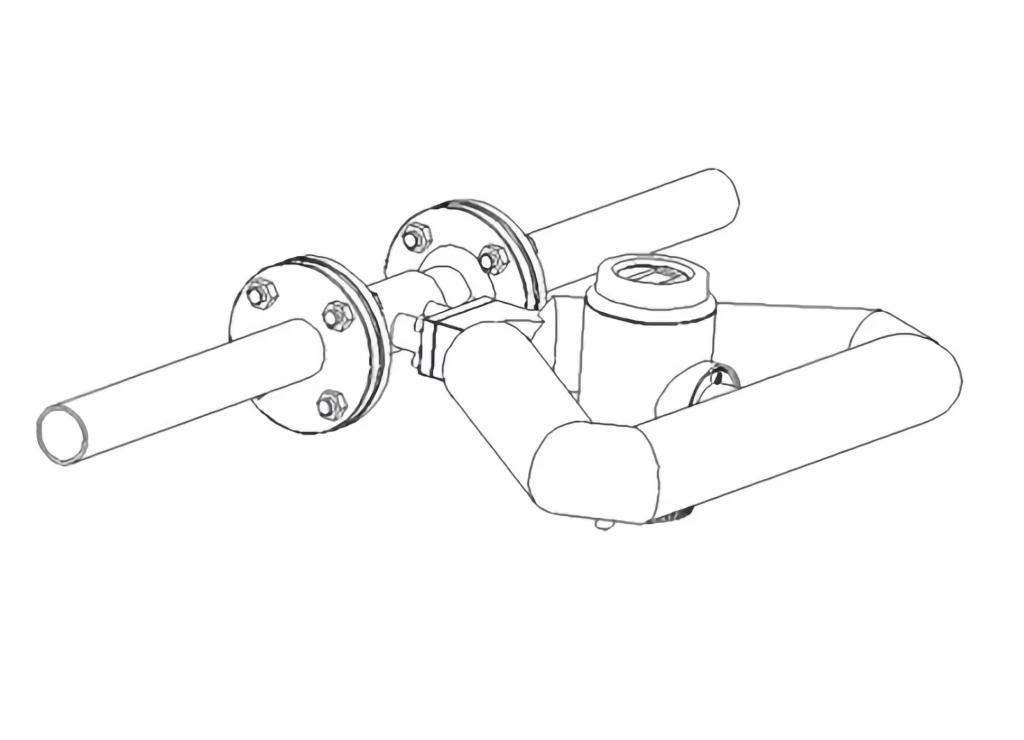

Horizontal pipes are installed on the side, which is suitable for liquids with a lot of bubbles and prevents residual bubbles. Bypass pipe installation

Bypass pipe installation Installation with buffer tank

Installation with buffer tank

Note: When the on-site pipeline is too large, a bypass device is required! Install away from areas prone to vibration. If this is not possible, use flexible hoses to connect both sides of the instrument.

Applications in the Brewing/Industrial Alcohol Industry

Traditional brewing involves multiple processes, primarily controlled manually. In the distillation and extraction process, operators rely heavily on experience, inevitably leading to errors that affect the quality of the raw spirit and cause production defects.

The discontinuity of the brewing process significantly contributes to the instability of the spirit’s quality, a persistent problem plaguing the liquor industry for many years. For a long time, the liquor industry has spared no effort in overcoming traditional production processes and achieving automation.

Since its inception, our company has been dedicated to the research and development and manufacturing of density and concentration measuring instruments. After years of dedicated research and experimentation, we have successfully developed a Coriolis principle online concentration meter capable of real-time online detection of alcohol concentration with an accuracy of 0.2%, adaptable to the high-temperature and humid environment of the distillation and extraction process. This represents a breakthrough and innovation in measuring instruments for the liquor industry.

Our company’s online concentration meter truly automates the distillation and extraction process in the liquor industry and will undoubtedly promote the development of the liquor industry.

Advantages:

- Integrated design, high product accuracy, good long-term stability, suitable for monitoring and control.

- Continuous measurement.

- Density, standard density, or specially calculated values are output at 4-20 mA.

- Temperature sensor provided.

More Density Measuring Instruments

The Coriolis Vibration Density Meter boasts advantages such as high measurement accuracy, fast measurement speed, and wide applicability. It is widely used in oil refining and blending, sugar, vegetable oil and beverage, papermaking, chemical (weak acid and alkali solution) measurement, winemaking, salt, and printing and dyeing industries.

Sino-Inst manufactures and supplies various types of density measuring instruments, supporting OEM and parameter customization. Please feel free to contact us.

Coriolis Vibration Density Meter - Sino-Inst

The Coriolis vibration density meter/concentration meter utilizes the relationship between the Coriolis force and the density of a liquid to measure its density. The concentration value at 20°C is then obtained using a density-concentration relationship table.

Product SKU: Coriolis Vibration Density Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)