The Coriolis Density Meter is based on the Coriolis effect, using the frequency change of the vibrating tube to monitor density. This method is accurate and reliable, and has a wide measurement range suitable for various fluid densities. The Coriolis density meter has very low pressure loss, giving it an inherent advantage in measuring the density of viscous fluids such as slurries.

Benefits

Technical Parameters

| Accuracy | ±0.001g/cc | ±1.0kg/m3 | |

| Measuring range | 0~3g/cc | 0~3000kg/m3 | 0~187.4 lb/ft3 |

| Repeatability | ±0.001g/c | ±0.1kg/m3 | ±0.006lb/ft3 |

| Process temperature effect (corrected) | ±0.001%g/cc) | ±0.1kg/m3 | (per °C) |

| Process pressure effects (corrected) | negligible | ||

| (1) The above accuracy applies to the calibration range 0.6 – 1.25g/cc (600 – 1250 kg/m3). | |||

| (2) The viscosity of the liquid can reach up to 2000cP. | |||

| (3) Temperature effect refers to the maximum measurement deviation caused by the process fluid temperature deviating from the factory calibration temperature. | |||

| (4) Pressure effect is defined as: the change in sensor flow and density sensitivity caused by the deviation of process pressure from the calibrated pressure. | |||

| process temperature | -10℃~+60℃ |

| ambient temperature | -10℃~+85℃ |

| temperature coefficient | 0.1kg/m3/℃ (after correction) |

| Built-in temperature sensor | PT100 |

| Wetted parts | Stainless steel, 316L, PTFE |

| Shell | IP65, aluminum alloy |

| Maximum working pressure | 10MPa |

| Test pressure | Tested at 1.5 times maximum working pressure |

| Tested at 1.5 times the maximum working pressure | |

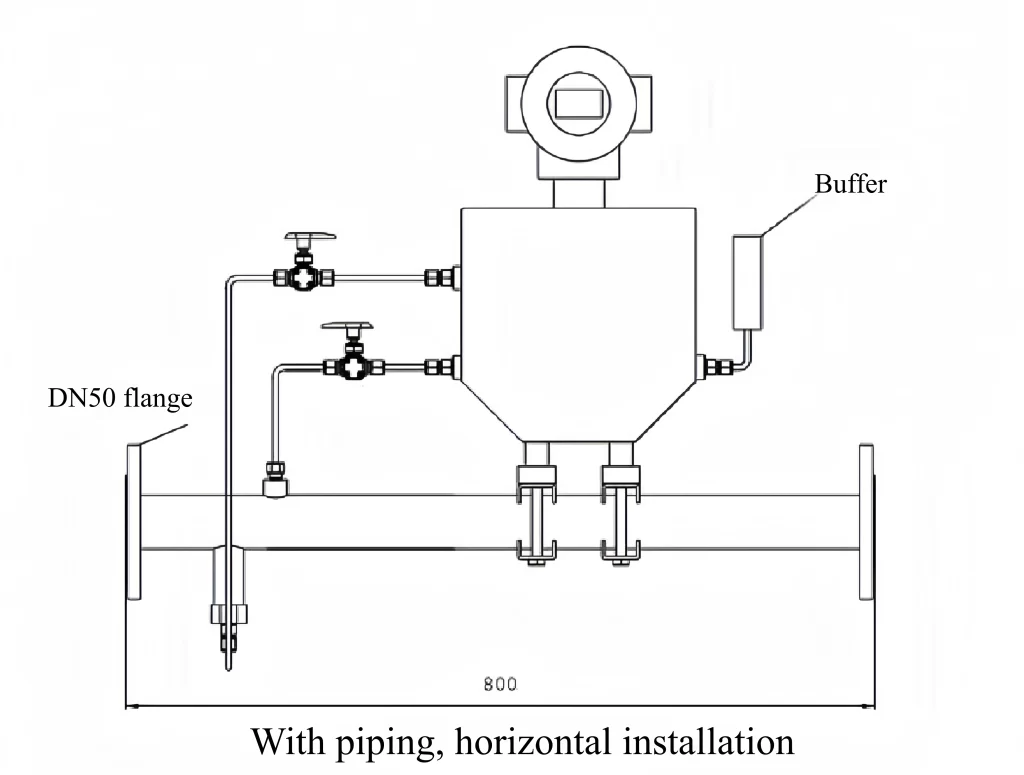

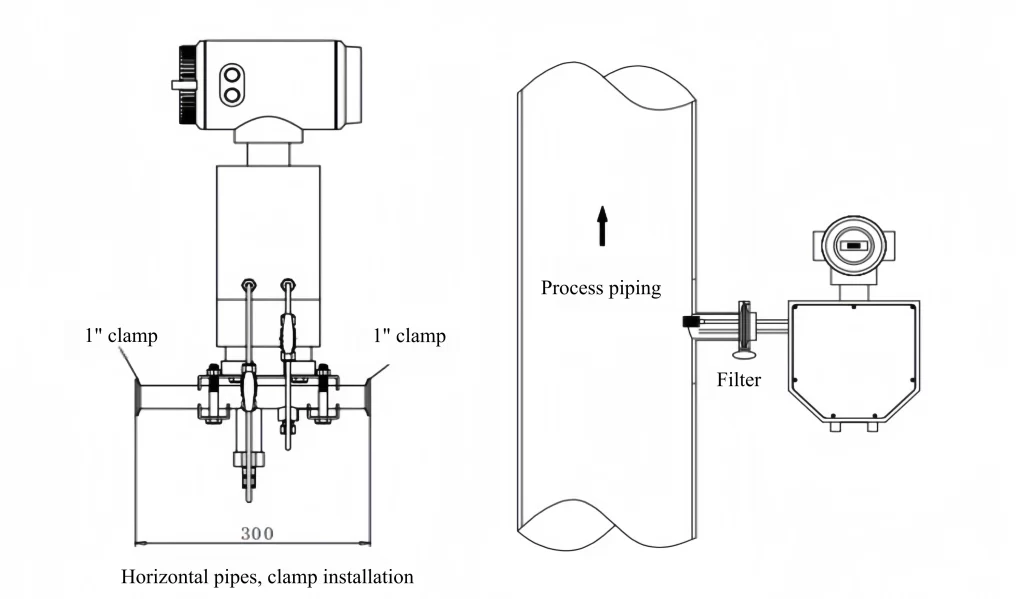

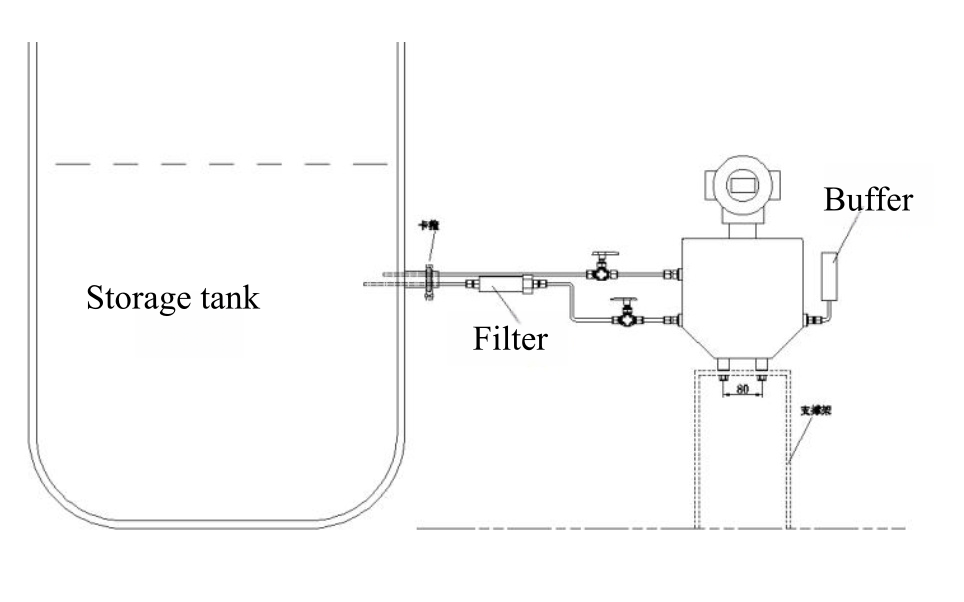

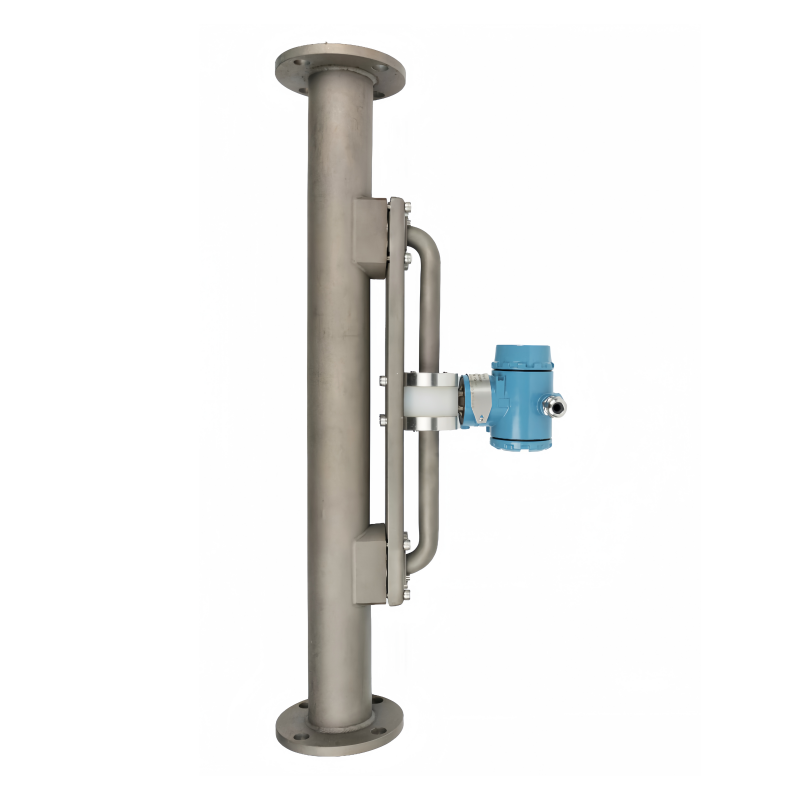

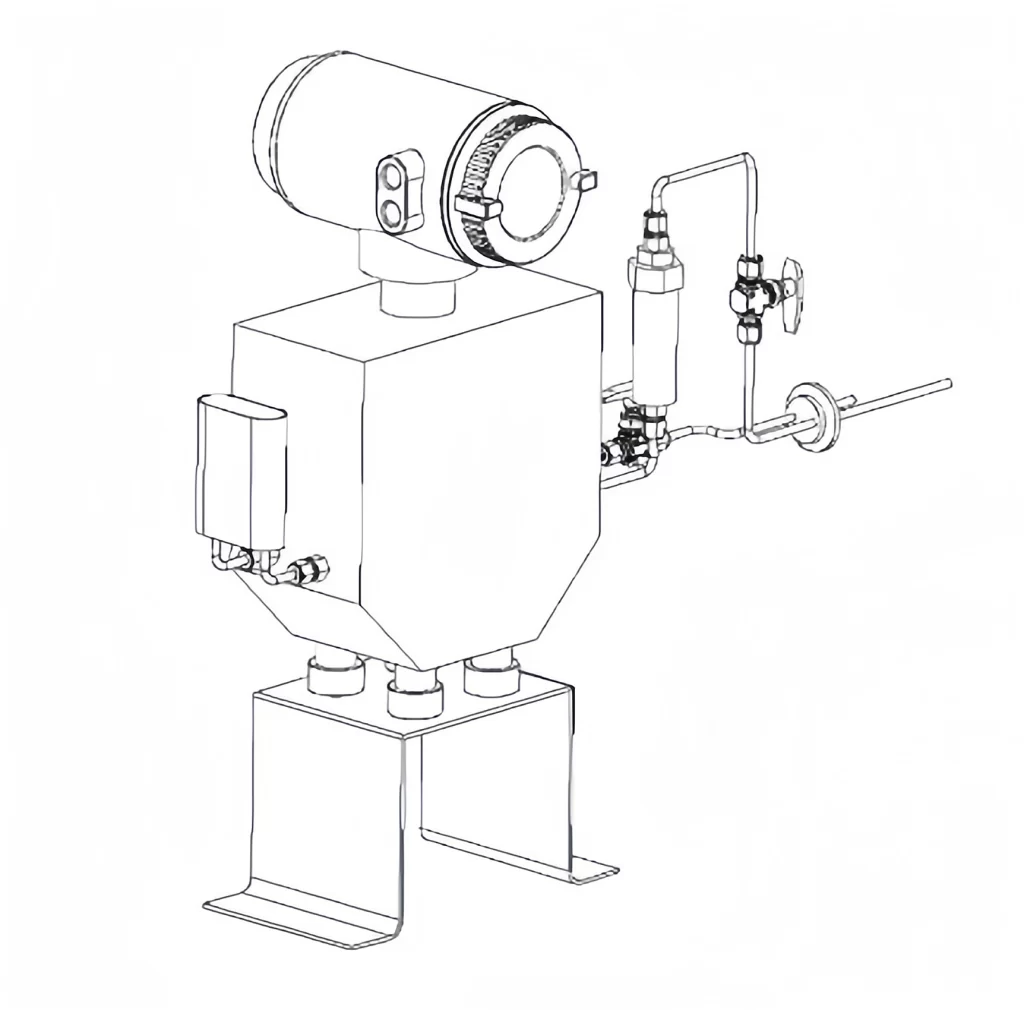

| Process connection type | flange |

| Tri-Clover (TC) Clamp | |

| Thread | |

| Explosion-proof certification | Exd IIB T6 Gb |

| Power requirements | 24VDC,50mA |

| output | Four-wire system, 4-20mA |

| Viscosity requirements | 0-20000cP |

Liquid and Material Compatibility

| Name | Name | Molecular formula | Concentration(%) | 316L | Hastelloy | Titanium Alloy | Zirconium | PTFE |

| Acid | Hydrochloric acid (without hydrofluoric acid) | HCl | 0-40 | × | ○ | × | ☆ | ☆ |

| sulfuric acid | H2SO4 | 0-50 | ○ | ☆ | ○ | ☆ | ☆ | |

| H2SO4 | 50-75 | × | ○ | × | ○ | ☆ | ||

| H2SO4 | 75-98 | ○ | ☆ | ○ | ○ | ☆ | ||

| Nitric acid | NHO3 | 0-100 | ○ | ○ | ○ | ○ | ☆ | |

| Phosphoric acid | H3PO4 | 0-98 | × | × | × | × | ☆ | |

| Base | sodium hydroxide | NaOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ |

| potassium hydroxide | KOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| calcium hydroxide | Ca(OH)2 | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Salt | sodium chloride | NaCl | 0-50 | × | ☆ | ☆ | ☆ | ☆ |

| Ammonium chloride | NH4Cl | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Ammonium sulfate | (NH4)2S04 | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Others | Urea | (NH2)2CO | 0-100 | ☆ | ☆ | ○ | ☆ | ☆ |

| sodium hypochlorite | NaOCl | 0-16 | × | ○ | × | ☆ | ☆ | |

| hydrogen peroxide | H2O2 | 0-90 | ☆ | ☆ | ○ | ☆ | ☆ | |

| ☆Recommended ○Use within specific concentration and temperature limits × Not used | ||||||||

Coriolis Density Meter Working Principle

The Coriolis density meter operates on the principle of the Coriolis force acting on a moving fluid, where the force is related to the fluid’s density, thus allowing the measurement of the fluid’s density.

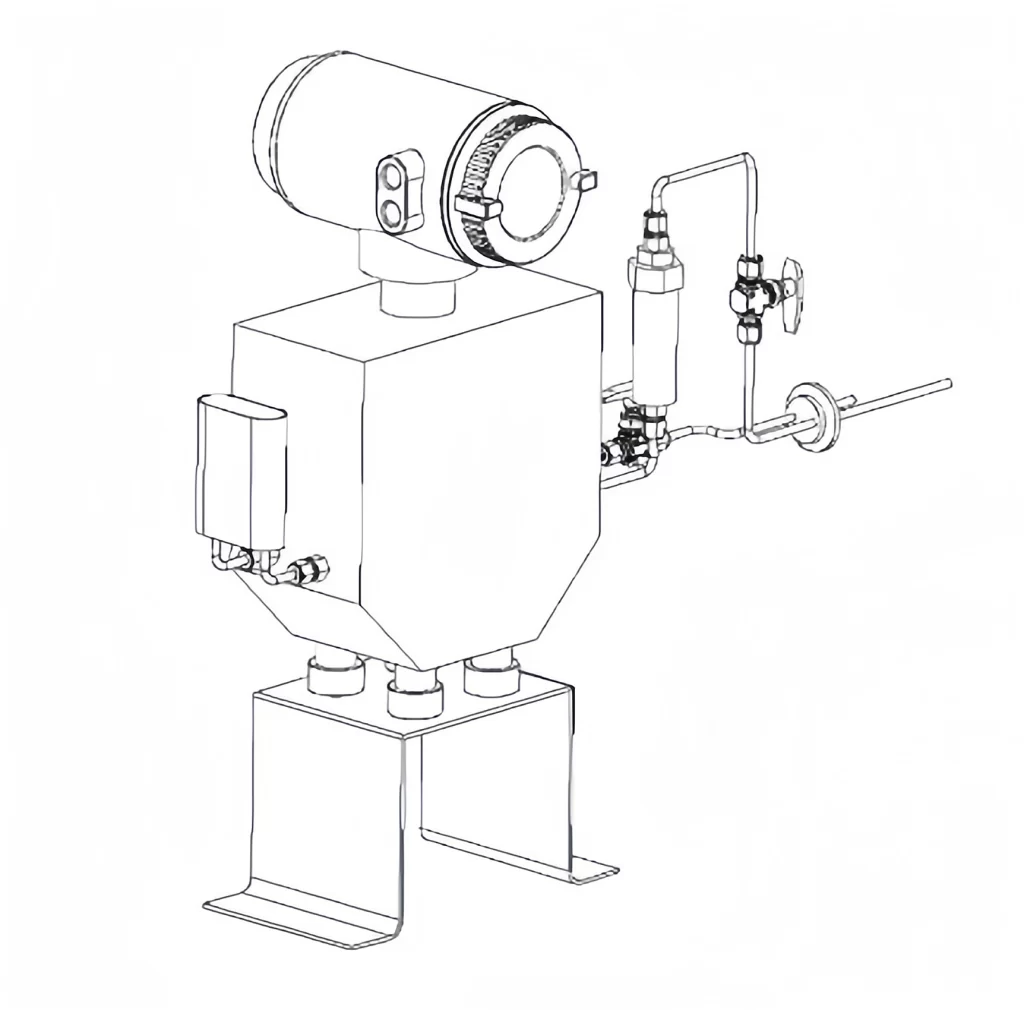

A Coriolis density meter contains one or more measuring tubes, forming a vibration system. As the fluid flows within the measuring tube, its inertia generates a force acting on the tube wall. The fluid density can be determined based on the vibration frequency of the measuring tube. A temperature sensor outside the measuring tube measures the tube’s temperature for temperature compensation.

This principle offers high stability, high precision, and good long-term stability, eliminating drift caused by sensors.

| Media Limitation: | Contains gas | Maximum liquid viscosity | |

| Conventional Liquids | Acid and alkaline solutions | Generally not used | 3000CP |

| 316L | Polytetrafluoroethylene | ||

Coriolis Density Meter Applications

Coriolis density meters are suitable for measuring the density of low-flow-rate media such as liquids, slurries, and suspensions.

- Interface detection in multi-product pipelines

- Brix sugar refining (sugar concentration)

- Wort specific gravity (brewing)

- Slurries

- Acid/alkali concentration control

- Product mixing

- Endpoint detection in batch reactions

- Solvent separation

| Petroleum and petrochemical industries | Interface detection; multi-oil pipelines |

| Brewing industry | Quality control; continuous online monitoring |

| Organic and inorganic chemical materials | Leak detection; underground storage tanks using brine |

| Pharmaceutical industry | Traditional Chinese medicine concentration, alcohol recovery |

| Battery industry | Lithium hydroxide, electrolyte, and sulfuric acid solution concentration |

Cases Share: Electrolyte Density Measurement in the Battery Industry

Lead-acid battery electrolyte is prepared from distilled water (or pure water) and concentrated sulfuric acid. The standard electrolyte density is 1.280 ± 0.005 g/cm³ (25℃).

If the electrolyte density is too low, the lead-acid battery will have insufficient power.

During production, the real-time electrolyte density needs to be monitored online. A Coriolis online density meter is used for measurement, with an error within ±0.005 g/cm³. A sealed structure is employed to reduce the corrosion of electronic components by acid mist and extend equipment life.

More Density Measurement Devices

The Coriolis online density meter/concentration meter uses the principle of calculating the density of a moving liquid based on the special law of the Coriolis force, and then converts it into a corresponding concentration value. It is suitable for measuring the density and concentration of media such as alcohol, gasoline, and diesel.

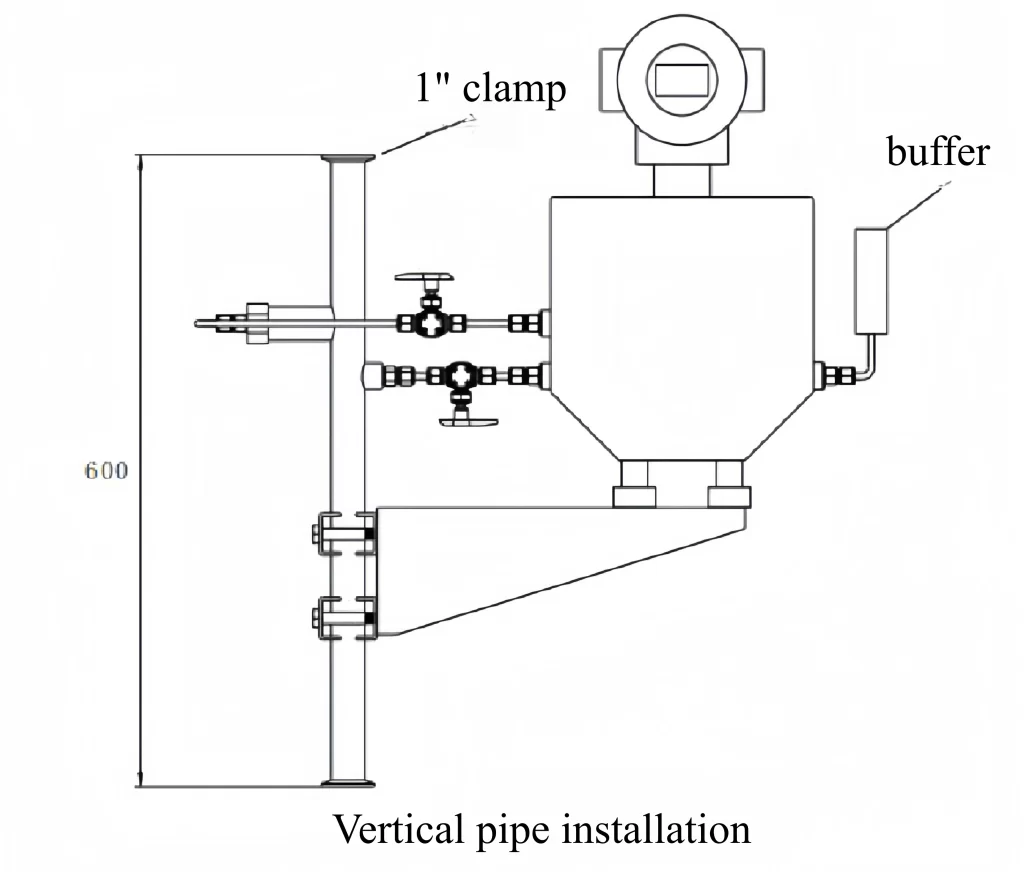

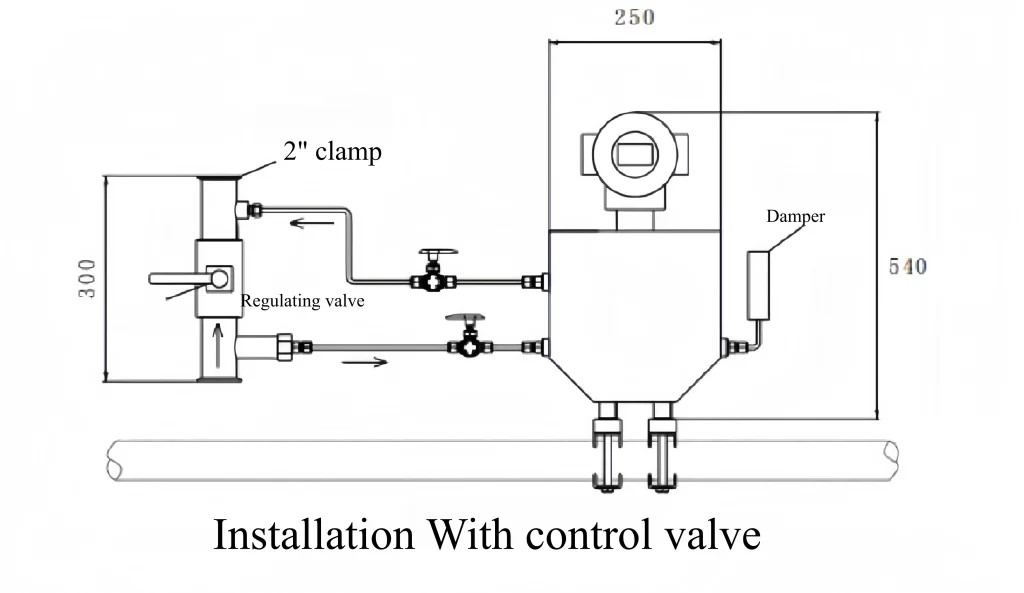

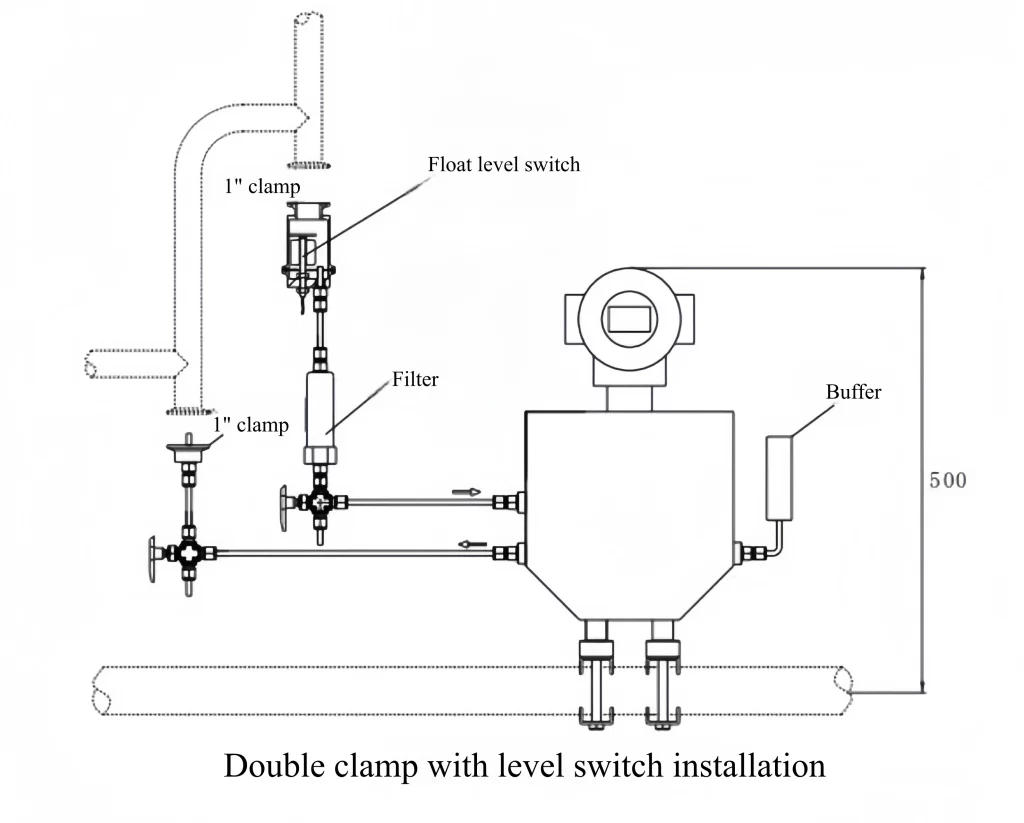

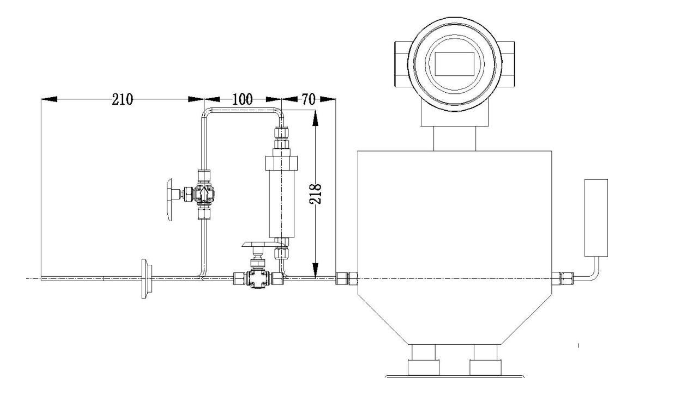

Sino-Inst supports customized parameters for its Coriolis online density meter/concentration meter, including pressure and installation method. Please feel free to contact us for density measurement solutions!

Coriolis Density Meter - Higher Accuracy & Stable |Sino-Inst

The Coriolis Density Meter is based on the Coriolis effect, using the frequency change of the vibrating tube to monitor density. This method is accurate and reliable, and has a wide measurement range suitable for various fluid densities. The Coriolis density meter has very low pressure loss, giving it an inherent advantage in measuring the density of viscous fluids such as slurries.

Product SKU: Coriolis Density Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)