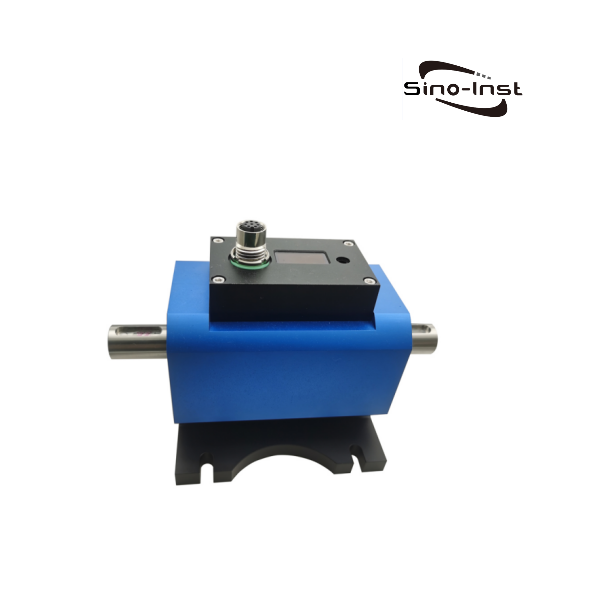

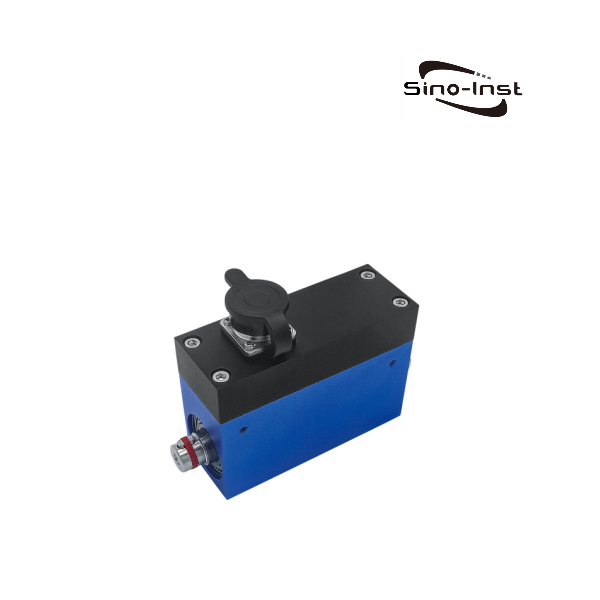

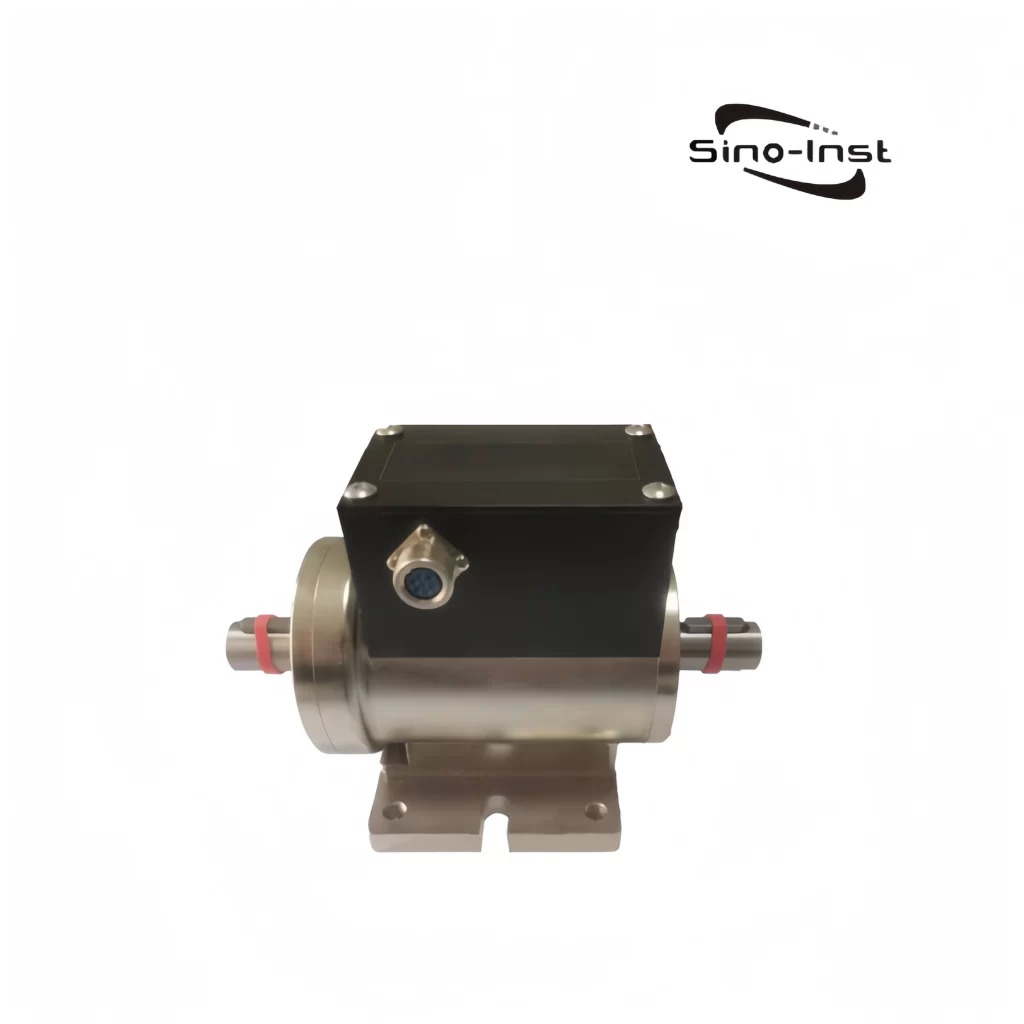

CL1-202 Dynamic Rotary Torque Sensor provides a unique solution for rotary and dynamic torque measurement. It is shaft-to-shaft type and can measure clockwise/counterclockwise torque. The normal speed is 1800RPM and can reach 4000RPM for a short time.

Features

- Can measure static torque and rotational torque;

- High precision, stable and reliable performance;

- Can run at high speed for a long time;

- Output forward and reverse torque signals;

- Both ends are keyed;

- The speed can reach 1800 rpm, and can reach 4000RPM in a short time;

CL1-202 Dynamic Rotary Torque Sensor Technical Parameters

| Range | 0-0.1,0.2,0.3,0.5,1,2,3, 5Nm |

| Output | 0.1-0.2Nm..0.6mVW±10%F.S.; 0.3-0.5Nm..0.8mVV±10%F.S.; 1-5Nm.1.3mVV±10%F.S. |

| Accuracy | ±0.1,±0.2%F.S. |

| Zero temperature effect | ±0.03%F.S. |

| Full scale temperature effect | ±0.03%F.S. |

| Compensated temperature range | -10~60℃ |

| Operating temperature range | -20~75℃ |

| Supply voltage | 5-10VDC |

| Input resistance | 350±20Ω |

| Output resistance | 350±10Ω |

| Response frequency | 100μS |

| Insulation resistance | ≥2000MΩ/100VDC |

| Safety overload | 150%F.S |

| Limit overload | 200%F.S. |

| Cable size | Φ5×3m |

| Material | Shaft material 17-4PH stainless steel, housing aluminum |

| Electrical connection | Red/E+, Black/E-, Green/S+, White/S- |

| Speed | Normal speed 1800RPM, short-term speed 4000RPM |

| Special shaft length | Customizable |

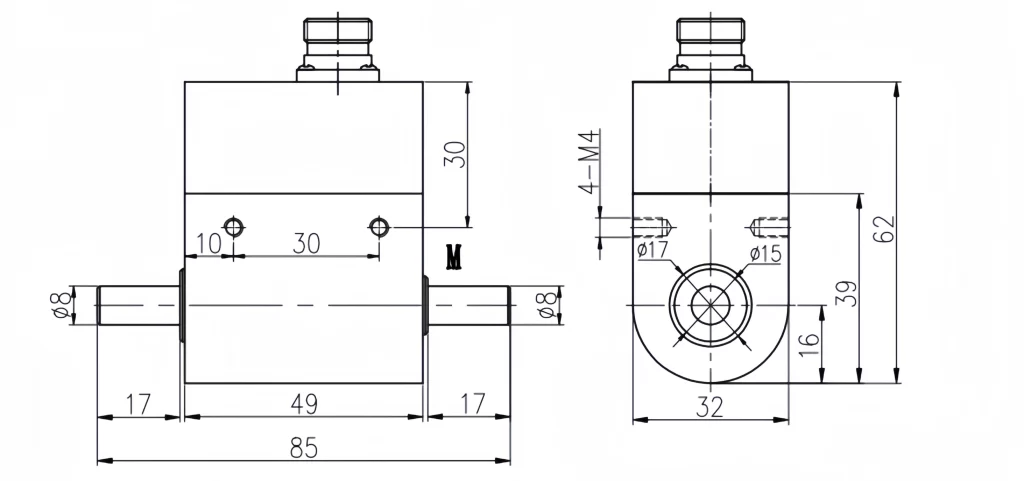

Dimensions

How is the maximum speed of a torque sensor determined?

The maximum speed of a torque sensor is mainly determined by its design structure, material properties, and manufacturing process. When determining the maximum speed of a torque sensor, the following key factors need to be considered:

Mechanical strength: The shaft and other rotating parts inside the sensor must be able to withstand the centrifugal force caused by high-speed rotation. If these parts are not strong enough, they may deform or break at high speeds.

Signal transmission method: For wired sensors, collector rings (slip rings) are a common signal and power transmission method. The design of the collector ring limits the maximum speed because excessive speeds may cause poor contact or increased wear. For wireless or contactless signal transmission (such as magnetic coupling, optical or radio frequency), such sensors can usually support higher speeds. Because there is no wear problem caused by physical contact.

Temperature effect: As the speed increases, the sensor and its surrounding environment may heat up due to friction and other reasons. Therefore, it is necessary to ensure that the materials and electronic components can work properly in high-temperature environments.

Bearing performance: Bearings are key components that support rotating parts. They must be able to withstand long-term high-speed operation without failure. Selecting the right bearing type (e.g., ball or roller bearings) and quality grade is critical to ensuring sensor reliability.

Electrical characteristics: Electronic components, including strain gauges, can be sensitive to temperature changes. They can also produce signal distortion under high-frequency vibrations. Therefore, the selection and arrangement of these components will also affect the maximum operating speed of the sensor.

Manufacturer specifications: Finally, each manufacturer will set a safe operating range based on the above factors and their own test results. The maximum allowable speed is provided as part of the product specifications.

In summary, the maximum speed of a torque sensor is the result of a combination of engineering considerations. Users should carefully refer to the technical specifications provided by the manufacturer when selecting a torque sensor for a specific application. To ensure that the selected device can meet the requirements under actual operating conditions.

More Torque Sensors and Solutions

A dynamic torque sensor is an instrument used to measure the torque of a rotating mechanical part under dynamic conditions. With the continuous improvement of industrial automation, the demand for accurate torque measurement of rotating parts is also increasing, so dynamic torque sensors are widely used in various applications.

Sino-Inst produces and supplies a full range of torque sensors and torque transmitters. If you need to purchase or have related technical questions, please feel free to contact our sales engineers!

CL1-202 Dynamic Rotary Torque Sensor - Sino-Inst

CL1-202 Dynamic Rotary Torque Sensor provides a unique solution for rotary and dynamic torque measurement. It is shaft-to-shaft type and can measure clockwise/counterclockwise torque. The normal speed is 1800RPM and can reach 4000RPM for a short time.

Product SKU: CL1-202 Dynamic Rotary Torque Sensor

Product Brand: Sino-Inst

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)