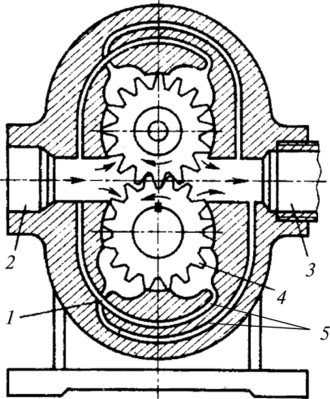

A circular gear flow transmitter is a positive displacement flow meter designed for high-precision, continuous or intermittent measurement of the volumetric or instantaneous flow rate of liquids in pipelines. It uses a pair of precision-machined cylindrical gears, driven by the fluid, to rotate. The fixed-volume cavity between the gears measures the volume of liquid passing through, making it a positive displacement flow meter. Its wide measurement range and high accuracy meet the requirements of most field conditions.

Customized Case Study

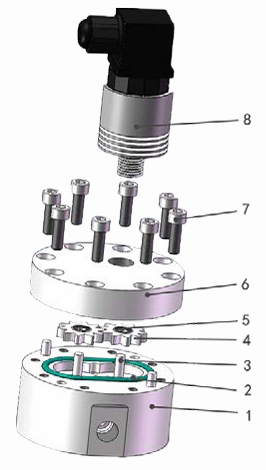

A customer from the United States wanted to measure the flow rate of cryogenic liquid nitrogen. He saw our product on our website and contacted us through the website. The final specifications were as follows:

- Gear flow meter

- Model: GF06

- Measuring range: 10-500 L/H

- Low temperature: -196°C

- Pressure: 22 psi

- Split-type local display

- G1/2 thread installation.

- 24VDC power supply

- 4-20 mA output signal + pulse signal output

Liquid nitrogen is an inert, colorless, odorless, low-viscosity, non-corrosive, non-flammable, and extremely low-temperature transparent liquid. Liquid nitrogen has a temperature as low as -196°C. Water in pipes and connecting components freezes quickly at low temperatures, causing blockages or unstable flow rates. Therefore, for liquid nitrogen flow measurement, our gear flowmeters are typically split-type. Both the pipes and the flowmeter require proper insulation.

Principle

As the medium flows, the gears mesh and rotate. The fluid flow creates a pressure differential between the inlet and outlet of the meter. Without power, a pair of gears rotate freely, filling the cavity between them with liquid. The liquid is expelled as the gears rotate, and measuring the number of gear revolutions provides the flow rate of the liquid passing through the meter.

The speed of the circular gear transmitter is detected by a sensor coil in a signal amplifier mounted on the meter case. The signal amplifier is not in contact with the measured medium. When the transmitter gears cut through the magnetic flux generated by the permanent magnets in the housing, this causes a change in the magnetic flux in the sensor coil.

The sensor coil feeds the detected signal into a preamplifier, which amplifies and shapes the signal to generate a pulse signal proportional to the flow rate. The signal is then fed into the unit conversion and flow totalizer circuits to display the accumulated flow value. It is also fed into the frequency-to-current conversion circuit, which converts the pulse signal into an analog current, indicating the instantaneous flow value.

Advantages

Corrosion resistance and strong resistance to contamination (acids and alkalis).

Ultra-short response time, suitable for measuring small flows and adding liquids in a short period of time.

Capable of operating at ultra-low temperatures up to -196°C, with custom high-temperature options up to 200°C.

Measures various viscous media (such as water, glue, honey, silicone, grease, etc.).

Class 0.5 measurement accuracy, 1:100 range ratio.

Integrates pulse output, analog, RS485, and switch output.

Positive displacement principle, no straight pipe sections required at either end.

Low starting pressure, suitable for gravity-flowing media.

High-pressure versions are also available, with a maximum pressure resistance of 40 MPa.

Lightweight and convenient, suitable for confined spaces, equipment, and laboratories.

Applications

- Measurement of resins and glue

- Measurement of hydraulic oils, lubricants, and greases

- Measurement of fuel oils

- Measurement of inks and asphalt

- Measurement of liquid nitrogen, cryogens, and solvents

- Measurement of edible oils, fish oils, and food fillings

- Measurement of fluids requiring chemical and corrosion protection

- Fluid quantitative control systems

Installation Requirements

The transmitter should be installed in an environment away from high temperatures, high mechanical vibration, strong magnetic interference, and strong corrosive environments. It should be installed in a location that is easily accessible for maintenance.

The transmitter should generally be mounted horizontally, and the sensor must be securely fastened to the assembly with screws. If vertical installation is necessary, the liquid must flow upward. The liquid should fill the pipe completely, and there should be no bubbles.

When installing the transmitter, the base centerline should be aligned with the pipe centerline, and the gasket at the connection should not protrude into the liquid.

If a flow control valve is required, it must be installed downstream of the sensor.

When installing the sensor on a new pipe, it is recommended to install a filter upstream of the transmitter to prevent impurities in the pipe from entering the transmitter.

To prevent maintenance from affecting normal liquid flow, a bypass line should be installed at the transmitter installation site.

Magnetic fields and similar interference sources near gear flow transmitters may affect the sensor’s signal pickup. The connection between the transmitter and the display instrument should use a metal shielded cable. The transmission cable shield should be grounded at the display instrument.

Other Flowmeters Suitable For Liquid Nitrogen Flow Measurement

Mass flowmeters: Suitable for applications with high flow rates and high accuracy requirements.

Cryogenic turbine flowmeters: Suitable for measuring small and medium liquid nitrogen flows, with a simple mechanical structure and low cost. They are suitable for liquid nitrogen filling and laboratory cryogenic systems.

Differential Pressure Flowmeter: Suitable for measuring large pipe diameters or high flow rates. Suitable for liquid nitrogen pipelines or industrial refrigeration systems. Requires a differential pressure transmitter for temperature compensation.

More Solutions for Liquid Nitrogen Measurement

- Case – Liquid Nitrogen Level Measurement

- Cryogenic Flow Meters Custom Cases

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- Industrial Liquid Nitrogen Flow Meters

Accurate flow measurement ensures safe production. Sino-Inst’s gear flowmeters offer high precision and accuracy. They can measure liquid nitrogen at temperatures as low as -196°C or liquids at temperatures as high as 200°C. Pressure resistance and material can be customized to meet your specific requirements. Need to select a model? Contact our technical support team directly to provide you with a tailored solution.

-1.jpg)